Method for preparing three-dimensional microporous graphene totally without participation of solution

A solution-free, graphene-free technology, applied in the field of inorganic synthesis, can solve problems such as affecting electrical conductivity and thermal conductivity, large impact on waste liquid environment, and graphene structure damage, and achieves the effects of simple operation, large-scale preparation, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, copper powder is used as catalyst growth three-dimensional graphene

[0030] First of all, the preparation work before the reaction: take a certain amount of copper powder and spread it in the ceramic boat, place the ceramic boat in the temperature zone of the tube furnace, turn on the vacuum pump to pump the internal pressure of the quartz tube to 5×10 -3 Below Torr, close the gas outlet valve, feed the argon gas with a flow rate of 400 milliliters per minute through the flowmeter to rush the air pressure back to normal pressure, continue feeding argon gas to exhaust the air (at this time, until the reaction is over, the gas outlet valve is opened to maintain normal pressure) pressure environment), the temperature of the tube furnace was raised to 1000 °C at a rate of 50 °C / min.

[0031] Next, the reaction stage: ①template preparation; turn off the argon gas, and change it into 200 ml per minute of hydrogen gas to reduce and anneal the copper powder for 2...

Embodiment 2

[0032] Embodiment 2, copper powder is used as catalyst growth three-dimensional graphene

[0033] The preparation method is basically the same as in Example 1, the difference is: in the ② growth material process in the reaction stage, alcohol vapor is introduced in the form of argon bubbling alcohol, and hydrogen is introduced at the same time, and the ratio of hydrogen to argon is 10 / 50 ml Every minute, the mixed gas is used as the carbon source.

Embodiment 3

[0034] Embodiment 3, copper powder is used as catalyst to grow three-dimensional graphene

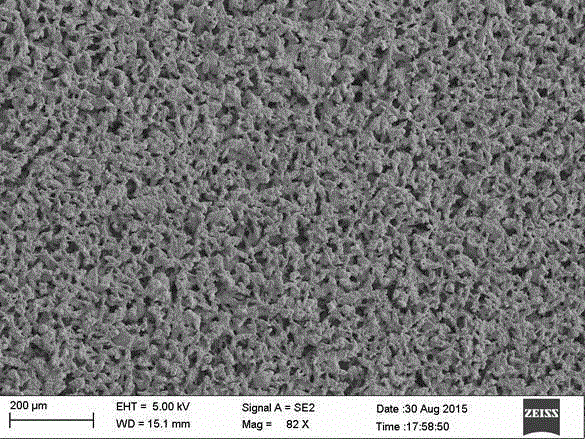

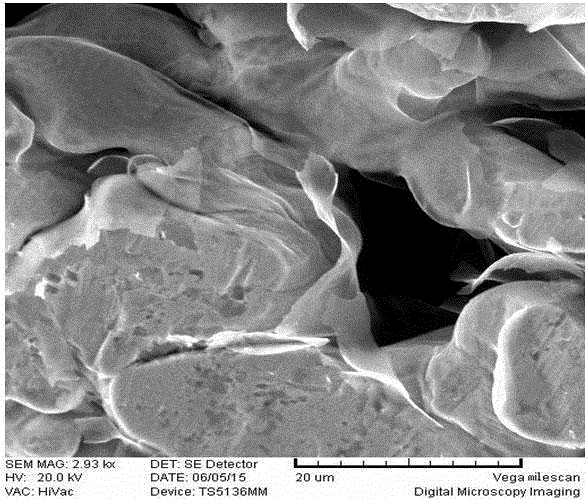

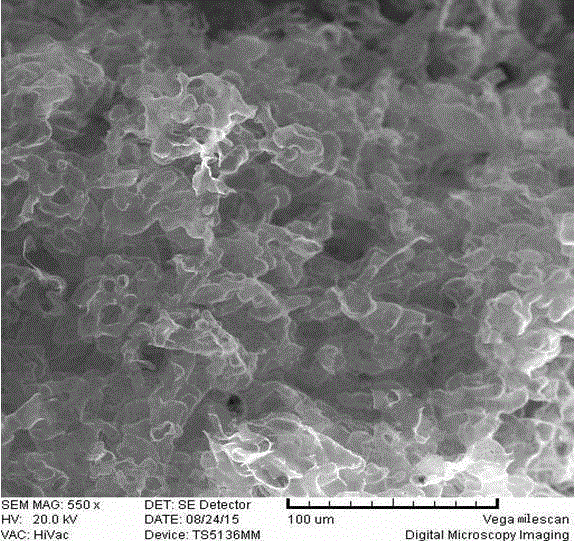

[0035] The preparation method is basically the same as in Example 1, except for: ② growing material process in the reaction stage. After preparing a three-dimensional microporous network copper template (such as figure 1 ), take it out and immerse it in the anisole solution dissolved in polymethyl methacrylate, then put it into the quartz tube, and directly enter the furnace temperature zone of 1000 degrees Celsius under the atmosphere of argon (the tube furnace can be moved flexibly). React for 20 minutes to prepare graphene.

[0036] 2. Transition metal compounds as catalyst precursors

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com