Europium-doped tungstate transparent glass ceramic and preparation method thereof

A technology of transparent glass and glass ceramics, applied in the field of europium-doped tungstate transparent glass ceramics and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

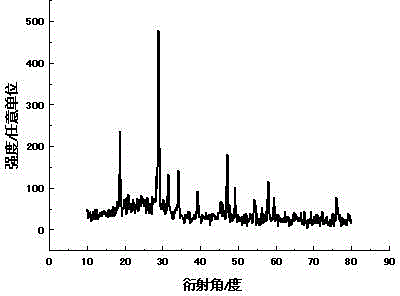

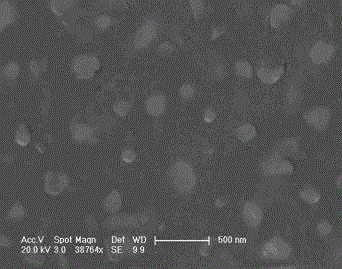

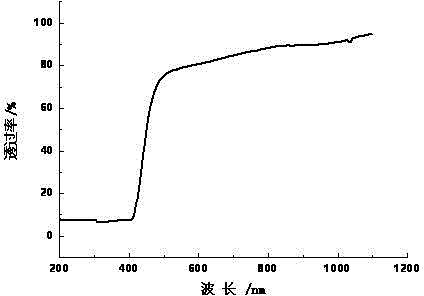

Embodiment 1

[0026] According to mass percentage 26CaCO 3 -10WO 3 -40SiO 2 -10H 3 BO 3 -8.5NaF-0.5Sb 2 O 3 -5Eu 2 O 3 , Weigh each component, and mix the above components thoroughly, put it in a corundum crucible, put it in a silicon molybdenum furnace, heat up to 1500 ℃, make the raw material melt into a liquid state, after 1 hour of constant temperature, the liquid in the crucible Pour it on a preheated stainless steel mold to solidify and shape it, quickly put it in a 500℃ muffle furnace, keep it warm for 1 hour, and then cool down to room temperature with the furnace, to prepare a europium-doped transparent tungstate glass; sample the transparent tungstate glass Put it in a box-type resistance furnace, heat up to 580°C at a heating rate of 5°C / min, keep it for 2 hours, then heat it up to 740°C at a heating rate of 4°C / min, keep it for 2 hours, and obtain europium-doped hyalotungstic acid Salt glass ceramics; cut the prepared europium-doped transparent tungstate glass ceramics with a cutt...

Embodiment 2

[0028] According to mass percentage 30CaCO 3 -10WO 3 -35SiO 2 -15H 3 BO 3 -5NaF-1.5Sb 2 O 3 -3.5Eu 2 O 3 , Weigh each component and mix the above components evenly, put it in a corundum crucible, put it in a silicon-molybdenum furnace, heat up to 1400 ℃, make the raw material melt into a liquid state, after 2 hours of constant temperature, the liquid in the crucible Pour it on a preheated stainless steel mold to solidify and shape it, quickly put it in a 500℃ muffle furnace, keep it warm for 1 hour, and then cool down to room temperature with the furnace, to prepare a europium-doped transparent tungstate glass; sample the transparent tungstate glass Put it into a box-type resistance furnace, heat it up to 580°C at a heating rate of 4°C / min, keep it for 2 hours, then heat it up to 760°C at a heating rate of 4°C / min, keep it for 1 hour, and obtain europium-doped hyaluronic acid Salt glass ceramics; cut the prepared europium-doped transparent tungstate glass ceramics with a cutting...

Embodiment 3

[0030] According to mass percentage 25CaCO 3 -15WO 3 -40SiO 2 -10H 3 BO 3 -5NaF-1Sb 2 O 3 -4Eu 2 O 3 , Weigh each component, and mix the above components thoroughly, put them in a corundum crucible, put them in a silicon molybdenum furnace, heat up to 1300 ℃, make the raw materials melt into a liquid state, after 3 hours of constant temperature, the liquid in the crucible Pour it on a preheated stainless steel mold to solidify and shape it, quickly put it in a 500℃ muffle furnace, keep it warm for 1 hour, and then cool down to room temperature with the furnace, to prepare a europium-doped transparent tungstate glass; sample the transparent tungstate glass Put it in a box-type resistance furnace, heat up to 620°C at a heating rate of 3°C / min, keep it for 1 hour, then heat it up to 740°C at a heating rate of 4°C / min, keep it for 2 hours, and obtain europium-doped hyalotungstic acid Salt glass ceramics; cut the prepared europium-doped transparent tungstate glass ceramics with a cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com