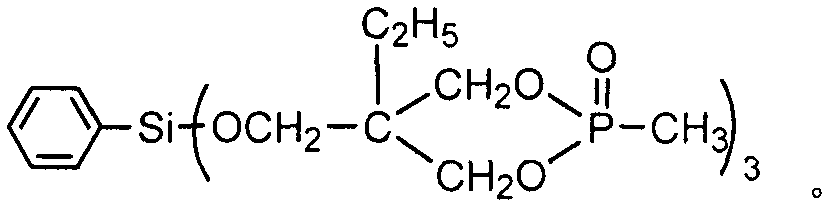

Fire retardant - phenyl tri-(phosphonia cyclomethoxy) silane compound and preparation method thereof

A technology of phenyltrimethoxysilane and phenyltrisilane, which is applied in the field of flame retardant phenyltrisilane compounds and their preparation, can solve the problems of limited application range, influence of polymer thermal stability and mechanical properties, etc. Stable physical and chemical properties, promoting flame retardant effect, and no three-waste emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

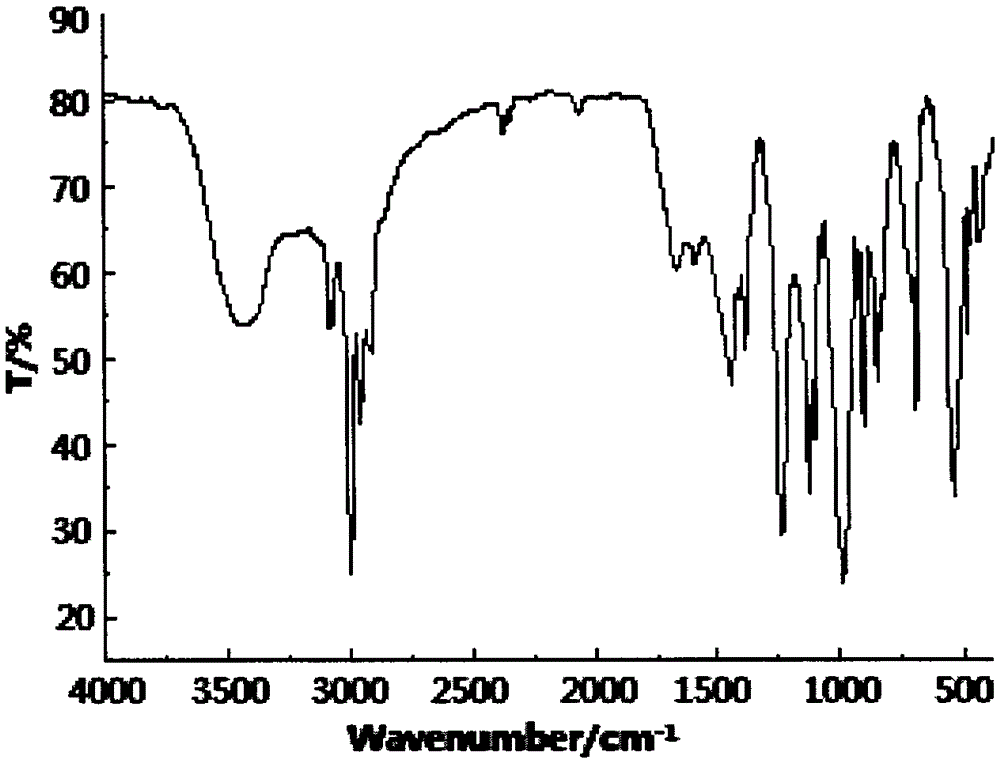

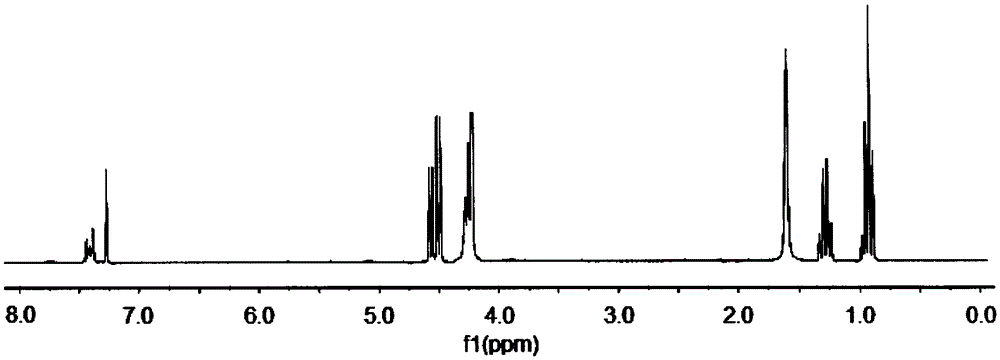

Embodiment 1

[0028] Example 1 In a 250ml four-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, replace the air in the bottle with nitrogen, and add 51.87g (0.32mol) of caged phosphate, 90ml of diethylene glycol dimethyl ether , 19.83g (0.10mol) phenyltrimethoxysilane and 1.45g dimethyl sulfate, heat up to 155°C, keep warm for 18h, remove diethylene glycol dimethyl ether (recycled) by distillation under reduced pressure, and cool to 50°C , then add 68ml of petroleum ether, stir to make the solid dispersed in petroleum ether, filter with suction and dry to get white solid phenyl tris (phosphacyclomethoxy) silane, product yield 85.0%, its decomposition temperature: 335 ±5°C.

Embodiment 2

[0029] Example 2 In a 150ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, replace the air in the bottle with nitrogen, and add 50.25g (0.31mol) of caged phosphate, 19.83g (0.10mol) of phenyl Trimethoxysilane and 1.35g dimethyl sulfate, heat up to 140°C, keep warm for 20h, cool to 50°C, add 68ml of petroleum ether, stir to disperse the solid in petroleum ether, filter with suction and dry to obtain a white solid Phenyltris(phosphacyclomethoxy)silane, the product yield is 83.7%, and its decomposition temperature: 335±5°C.

Embodiment 3

[0030] Example 3 In a 250ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, replace the air in the bottle with nitrogen, and add 53.49g (0.33mol) of caged phosphate ester, 100mlDMF, 19.83g (0.10mol) Phenyltrimethoxysilane and 0.80g methyl p-toluenesulfonate, heat up to 130°C, keep warm for 22h, distill off DMF (recycled) under reduced pressure, cool to 50°C, add 68ml of petroleum ether, stir to make the solid Disperse in petroleum ether, filter with suction, and dry to obtain white solid phenyltris(phosphacyclomethoxy)silane with a product yield of 86.4%, and its decomposition temperature: 335±5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com