A method of coating the inner wall of an atomic gas to slow down the relaxation of atomic spins

A technology of atomic gas chamber and atomic spin, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of increasing the uncontrollable risk of atomic gas chamber, the performance change of atomic gas chamber, danger, etc. , to achieve the effects of increasing the macroscopic atomic spin relaxation time, optimizing the coating process conditions, and optimizing the size of the connecting pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

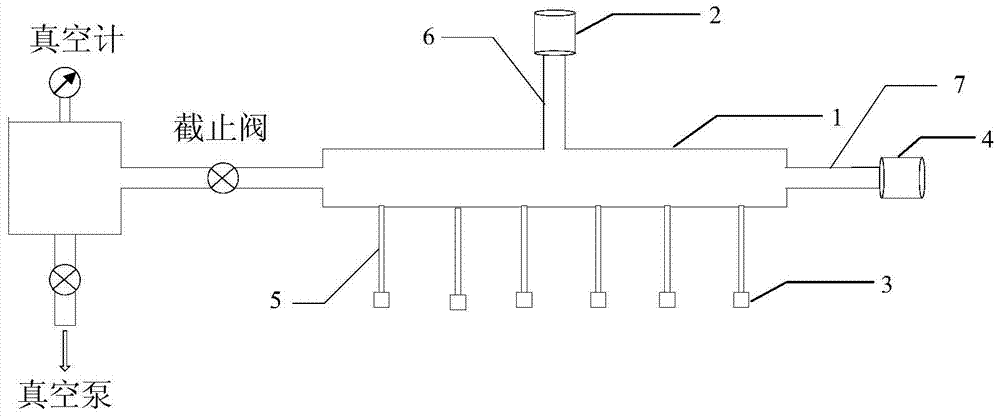

Embodiment 1

[0043] Firstly, the glass bulbs of the 6 atomic gas chambers 3 are cleaned and dried, and then welded to the glass main pipe 1 through 6 glass thin tubes 5. The diameter of the glass thin tube 5 is 2.5 mm, and the diameter of the glass main pipe 1 is 20 mm. 10 mg of the rubidium source was placed in the glass container 2, and welded to the glass main pipe 1 through a glass thin tube 6, and the diameter of the glass thin tube 6 was 8 mm. 500 mg of titanium hydride was placed in the glass container 4, and it was welded to the glass main pipe 1 through the glass thin tube 7, and the diameter of the glass thin tube 7 was 8 mm.

[0044] Connect the glass main pipe 1 to the vacuum system, and use the vacuum pump to evacuate the entire pipeline to a pressure of 3×10 - 4 Pa; use the method of distillation to heat the glass container 2 containing the rubidium source, so that the rubidium source diffuses into each atomic gas chamber 3 in the form of steam; the heating temperature is 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com