Method for recovering light hydrocarbon and hydrogen from tail gas of petrochemical plant

A petrochemical plant and tail gas technology, applied in combustion methods, liquefaction, incinerators, etc., can solve the problems of unattainable emission standards, potential safety hazards, and low product purity, and achieve the effect of small investment, large economic value, and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

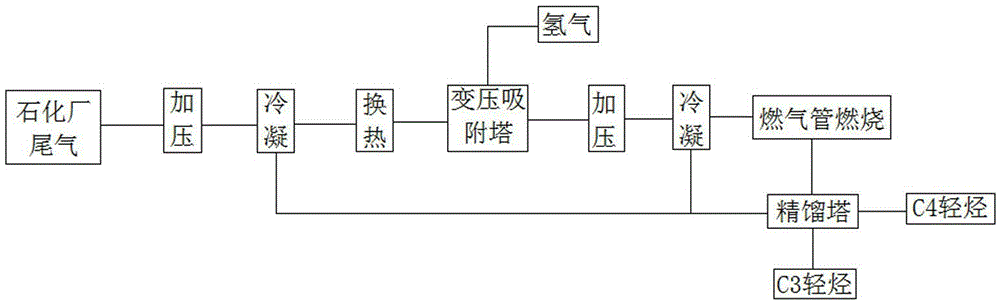

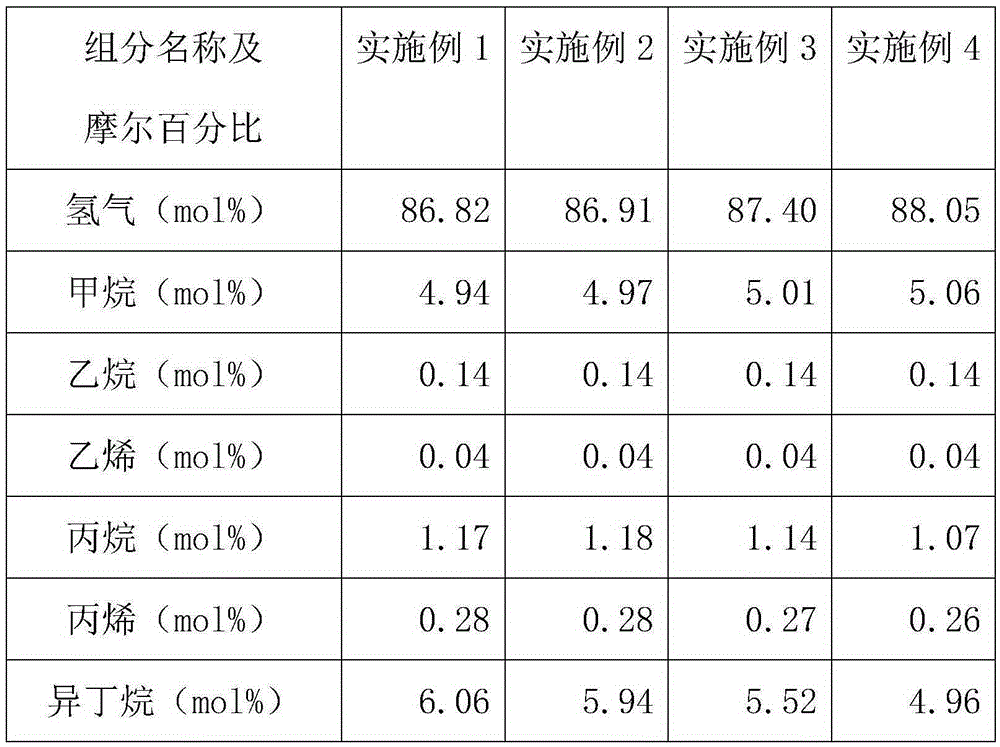

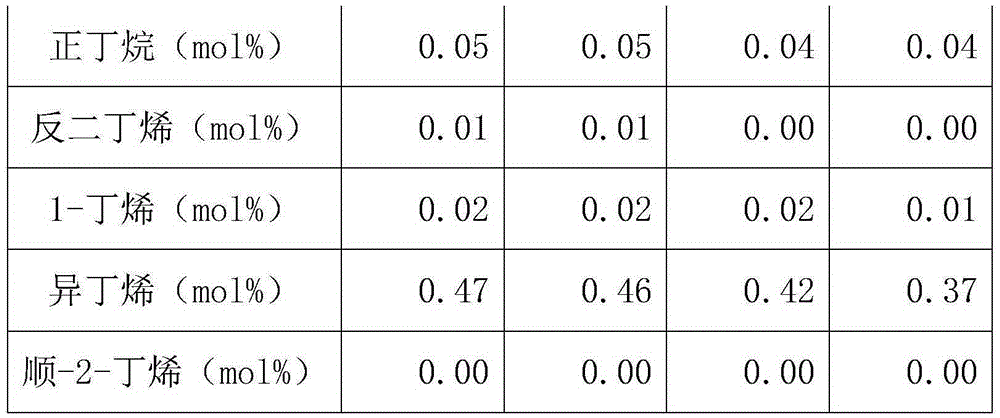

[0024] A method for recovering light hydrocarbons and hydrogen from petrochemical plant tail gas, characterized in that: the petrochemical plant tail gas is compressed to 3.0Mpa; the compressed tail gas is condensed to -5°C, and high hydrocarbon substances such as C3 and C4 in the tail gas are converted from gaseous state It becomes liquid, and the liquid light hydrocarbons rich in C3 and C4 are separated through the gas-liquid separation tank. The non-condensable gas (pressure 3.0Mpa, temperature -5°C) in the gas-liquid separation tank is heated to 5°C through a heat exchanger. The heating medium is factory circulating water. The purpose of this step is to prevent liquid material from entering the PSA unit by controlling the temperature entering the PSA unit. After heating, the non-condensable gas enters the pressure swing adsorption tower for pressure swing adsorption, and the preheated gas (pressure 3.0Mpa, temperature 5°C) enters the pressure swing adsorption device. The ...

Embodiment 2

[0026] A method for recovering light hydrocarbons and hydrogen from petrochemical plant tail gas, characterized in that: the petrochemical plant tail gas is compressed to 2.5Mpa; the compressed tail gas is condensed to 0°C, and high hydrocarbon substances such as C3 and C4 in the tail gas change from gaseous state to It is in a liquid state, and the liquid light hydrocarbons rich in C3 and C4 are separated through the gas-liquid separation tank. The non-condensable gas (pressure 2.5Mpa, temperature 0°C) in the gas-liquid separation tank is heated to 15°C through a heat exchanger, and the heating medium Circulate water for factories. The purpose of this step is to prevent liquid material from entering the PSA unit by controlling the temperature entering the PSA unit. After heating, the non-condensable gas enters the pressure swing adsorption tower for pressure swing adsorption, and the preheated gas (pressure 2.5Mpa, temperature 15°C) enters the pressure swing adsorption device...

Embodiment 3

[0028] A method for recovering light hydrocarbons and hydrogen from petrochemical plant tail gas, characterized in that: the petrochemical plant tail gas is compressed to 2.2Mpa; the compressed tail gas is condensed to -5°C, and high hydrocarbon substances such as C3 and C4 in the tail gas are converted from gaseous state It becomes liquid, and the liquid light hydrocarbons rich in C3 and C4 are separated through the gas-liquid separation tank. The non-condensable gas (pressure 2.2Mpa, temperature -5°C) in the gas-liquid separation tank is heated to 10°C through a heat exchanger. The heating medium is factory circulating water. The purpose of this step is to prevent liquid material from entering the PSA unit by controlling the temperature entering the PSA unit. After heating, the non-condensable gas enters the pressure swing adsorption tower for pressure swing adsorption, and the preheated gas (pressure 2.2Mpa, temperature -5°C) enters the pressure swing adsorption device. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com