Package-on-package structure of chip and package-on-package method

A stacked packaging and chip technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of inconsistent tail wires, breakage and debonding, vibration fatigue, etc., and achieve the effect of reducing packaging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

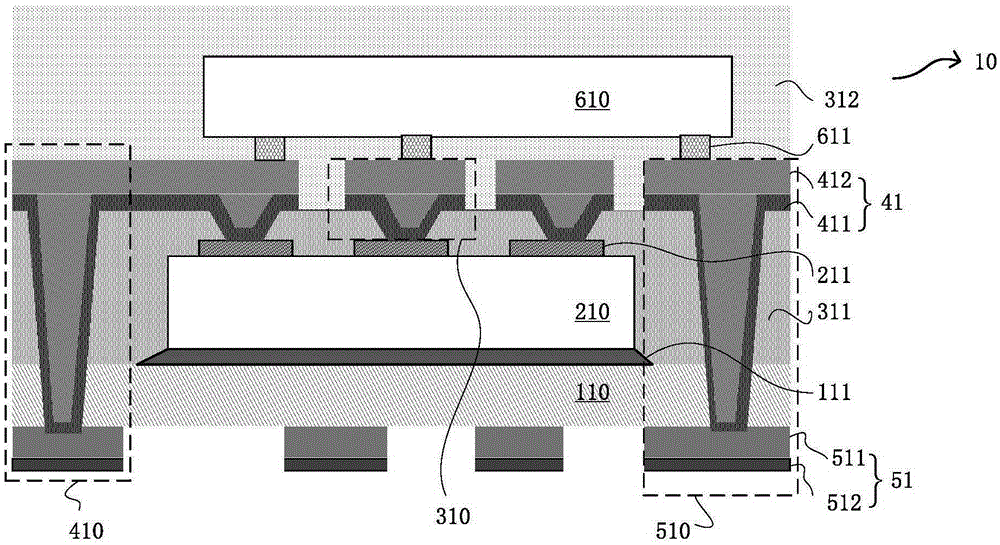

[0074] figure 1 It shows a schematic structural diagram of the stacked package structure of the first embodiment of the present invention. The package structure 10 mainly includes: a substrate 110, a first die 210, a first encapsulation body 311, a plurality of isolated interconnection bodies 310, a plurality of first redistribution bodies 410, a plurality of isolated penetrating bodies 510, The second die 610.

[0075] The substrate 110 may include semiconductor materials (such as silicon, germanium, indium antimonide, gallium arsenide, indium arsenide, gallium nitride, etc.), insulating materials (epoxy, polyester glass, silicon dioxide, polytetrafluoroethylene, etc.) Glass, ceramics, etc.) or a combination thereof. The packaging substrate 110 includes opposite first and second surfaces.

[0076] Both the first die 210 and the second die 610 include opposite active surfaces and back surfaces. The device layers of the first die 210 and the second die 610 are located on the acti...

no. 2 example

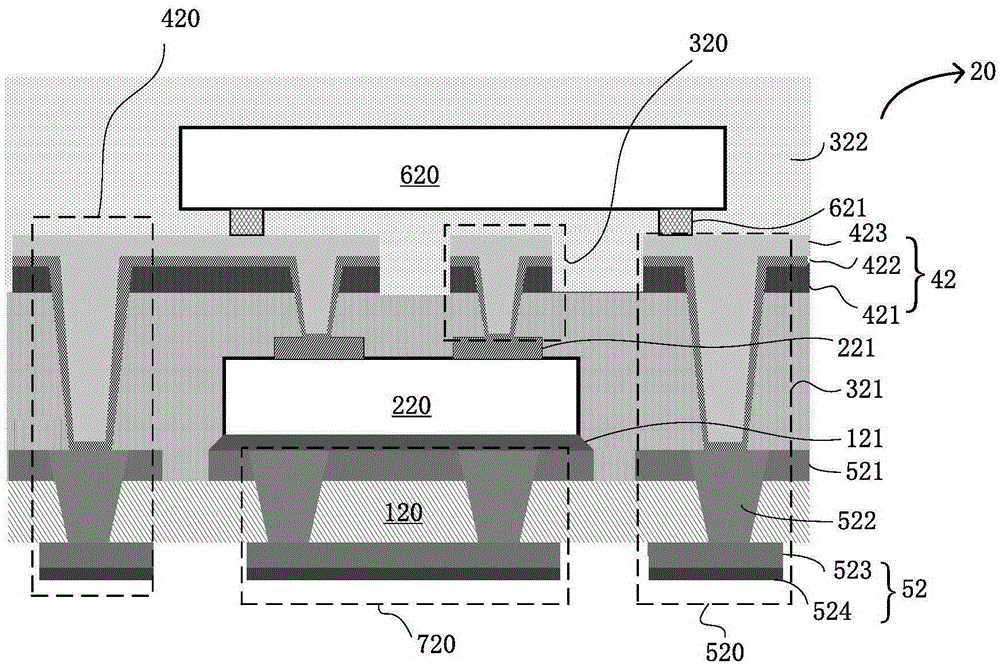

[0088] figure 2 The structure diagram of the stacked package structure of the second embodiment of the present invention is shown. The stacked package structure 20 includes: a substrate 120, a first die 220, a first encapsulation body 321, a plurality of isolated interconnections 320, a second encapsulation body 322, and a plurality of isolated first redistribution bodies 420, a plurality of isolated through bodies 520, a second die 620, a patterned conductive layer 521, and at least one second redistribution body 720.

[0089] The difference between this embodiment and the first embodiment is that the stacked package structure 20 further includes a conductive layer 521 and a second redistribution body 720. The patterned conductive layer 521 is formed on the first surface of the substrate 120, and the back surface of the first die 220 is electrically connected to the conductive layer 521 through the conductive adhesive layer 121, thereby leading the back electrode of the first d...

no. 3 example

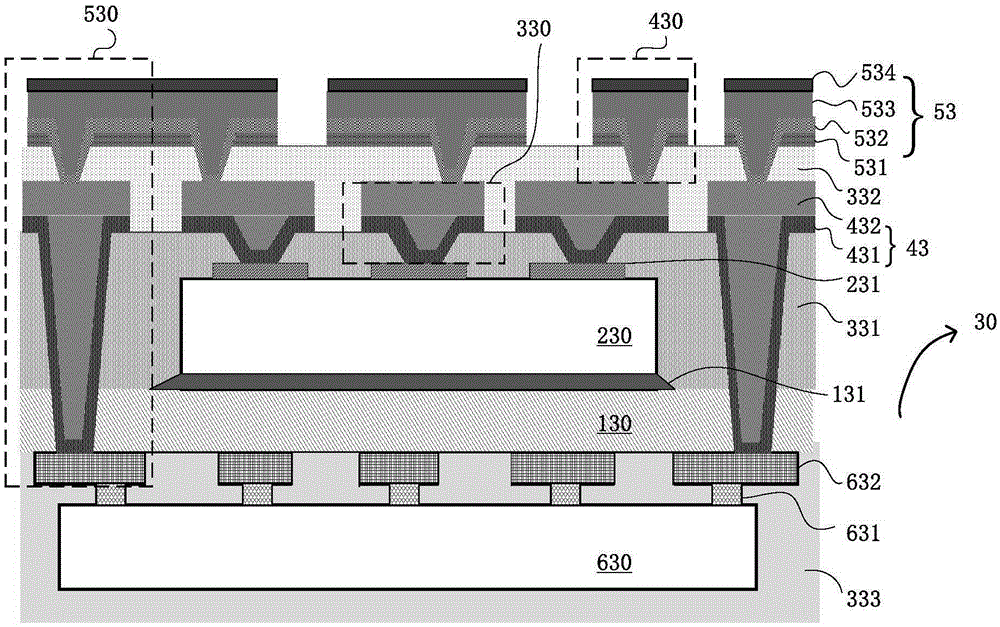

[0099] image 3 The structure diagram of the stacked package structure of the third embodiment of the present invention is shown. The stacked package structure 30 includes: a package substrate 130, a first die 230, an adhesive layer 131, a plurality of isolated interconnections 330, a first encapsulation body 331, and a plurality of isolated first redistribution bodies 430 , A plurality of isolated penetrating bodies 530, a second encapsulating body 322, a second die 630, and a third encapsulating body 333.

[0100] The back surface of the first die 230 is mounted on the first surface of the substrate 130 through the adhesive layer 131, and the substrate 130 also has a second surface opposite to the first surface. The first encapsulation body 331 covers the first die 230. The interconnection body 330 includes a first portion extending from the surface of the first encapsulation body 331 and a second portion extending from the surface of the first encapsulation body 331 to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com