Sapphire composite substrate and preparing method thereof

A composite substrate, sapphire technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low light extraction efficiency of light-emitting diodes, and achieve the effects of improved light extraction efficiency, improved brightness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

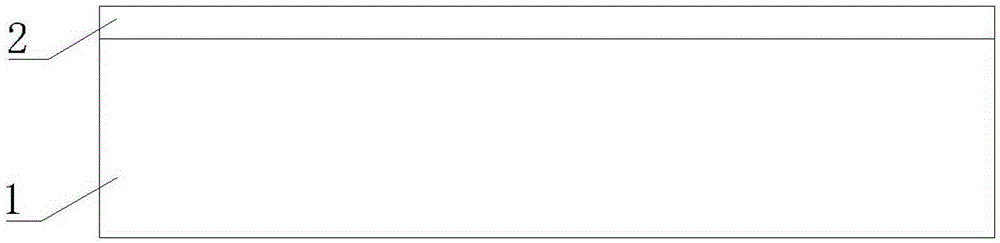

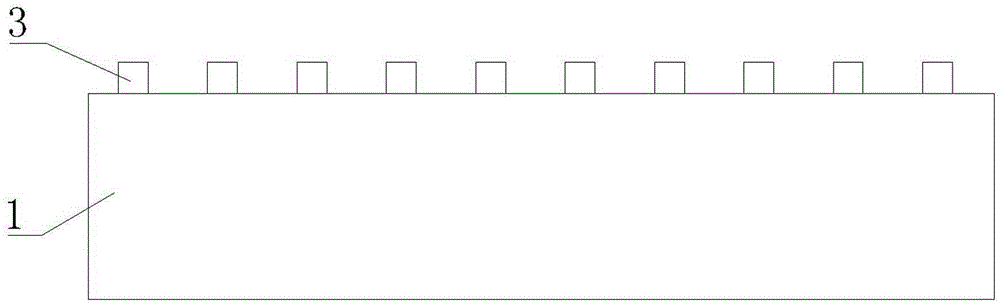

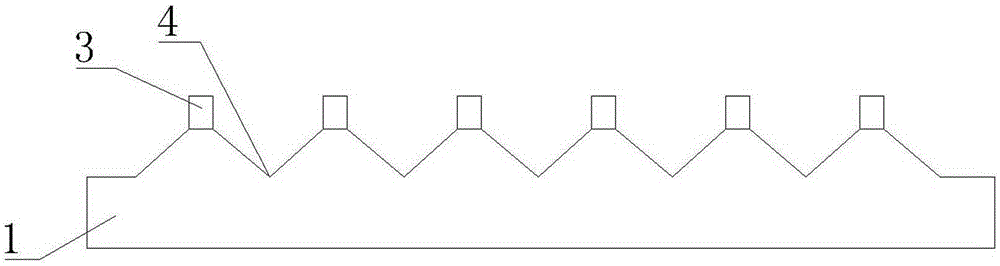

[0033] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a sapphire composite substrate includes a sapphire substrate 1, and a mask layer 2 is arranged on the sapphire substrate 1. The mask layer 2 forms a pattern mask layer 3 through photolithography or corrosion, and the pattern mask layer 3 protects and corrodes the sapphire. A patterned sapphire pattern layer 4 is formed on the substrate 1, and an aluminum oxide layer 5 is arranged on the patterned sapphire pattern layer 4. The thickness of the aluminum oxide layer 5 is 10-14nm or 101-500nm; the bottom of the adjacent pattern on the patterned sapphire pattern layer 4 Adhere to each other, the thickness of the mask layer is 10-5000nm, the mask layer is SiO2 mask layer 2, and the graphics on the SiO2 mask layer 2 are arranged in square or hexagonal arrangement.

[0034] The preparation method of the sapphire composite substrate of the present embodiment is a wet etching example, comprising steps: ...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, the difference is:

[0045] The preparation method is an example of dry etching, including steps:

[0046] 1. Choose a sapphire flat piece

[0047] 2. Using SiH4 / N2 mixed gas containing 5% SiH4 and N2O gas to deposit a SiO2 mask layer 2 with a thickness of 10-5000 nm on the sapphire flat sheet by plasma-enhanced vapor-phase chemical deposition.

[0048]3. Coating a layer of photoresist on the SiO2 mask layer 2, using photolithography technology to perform photoetching on the areas without patterns, so that the areas with patterns are protected by the photoresist to form the pattern mask layer 3.

[0049] 4. Using RIE to etch the SiO2 mask layer 2 with CF4 gas to obtain a pattern mask layer 3 with patterns arranged in a square or hexagonal arrangement.

[0050] 5. Continue to etch the sapphire to the bottom of the sapphire pattern by using BCl3, Cl3, H2, Ar, etc. by dry ICP, so that the bottoms of adjacent patterns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com