Electrode of electrochemical battery, electrochemical battery employing electrode and preparation method of electrochemical battery

A battery electrode and electrochemical technology, applied in the field of electrochemical batteries, can solve problems such as being vulnerable to damage and poor performance of flexible batteries, and achieve the effects of reducing the processing area, increasing energy density, and improving self-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

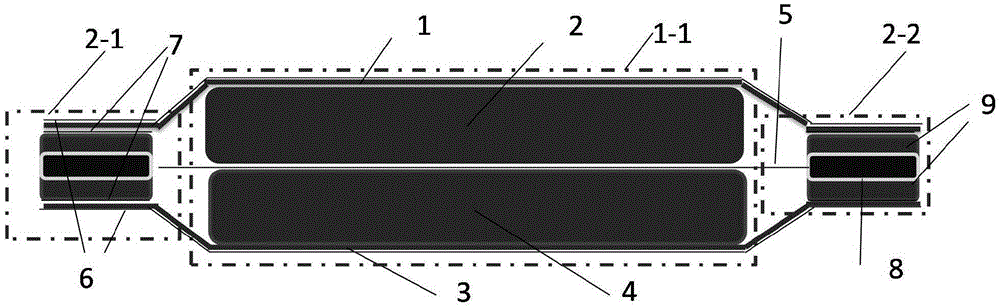

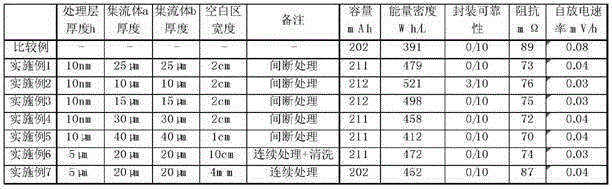

[0037] Such as figure 1 As shown, it is a schematic diagram of the cross-sectional structure of the electrochemical cell corresponding to the present embodiment, and it can be obtained from the figure that the battery of the present invention is divided into two parts, the cell main body 1-1 and the packaging area 2-1 / 2-2; The core main body 1-1, the negative electrode coating 2 is applied to one surface of the negative electrode current collector 1 as the packaging material, and the positive electrode coating 4 is applied to one surface of the positive electrode current collector 3 as the packaging material, and then separated with the separator 5 Laminates; for the packaging area 2-1 / 2-1, it is mainly composed of a water barrier layer (ie, the negative electrode collector 1 and the positive electrode collector 3 as the packaging material) and the sealing layer. In the position of the sealing area, the negative electrode collector 1 and The positive current collector 3 has un...

Embodiment 2

[0047] The difference from Example 1 is that it includes the following steps:

[0048] Initial membrane preparation: apply the above-mentioned positive electrode slurry on an aluminum foil with a thickness of 10 μm to obtain a coating film area with a length of 60 cm and a width of 50 cm, and the width of the empty foil material area is 4 cm to obtain an initial positive electrode sheet; apply the above-mentioned negative electrode slurry On a copper foil with a thickness of 10 μm, a coating area with a length of 60 cm and a width of 50 cm is obtained, and the width of the empty foil area is 4 cm to obtain an initial negative electrode sheet;

[0049] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0051] The difference from Example 1 is that it includes the following steps:

[0052] Preparation of the initial membrane: apply the above-mentioned positive electrode slurry on an aluminum foil with a thickness of 15 μm to obtain a coating film area with a length of 60 cm and a width of 50 cm, and the width of the empty foil material area is 4 cm to obtain an initial positive electrode sheet; apply the above-mentioned negative electrode slurry On a copper foil with a thickness of 15 μm, a coating area with a length of 60 cm and a width of 50 cm is obtained, and the width of the empty foil area is 4 cm to obtain an initial negative electrode sheet;

[0053] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com