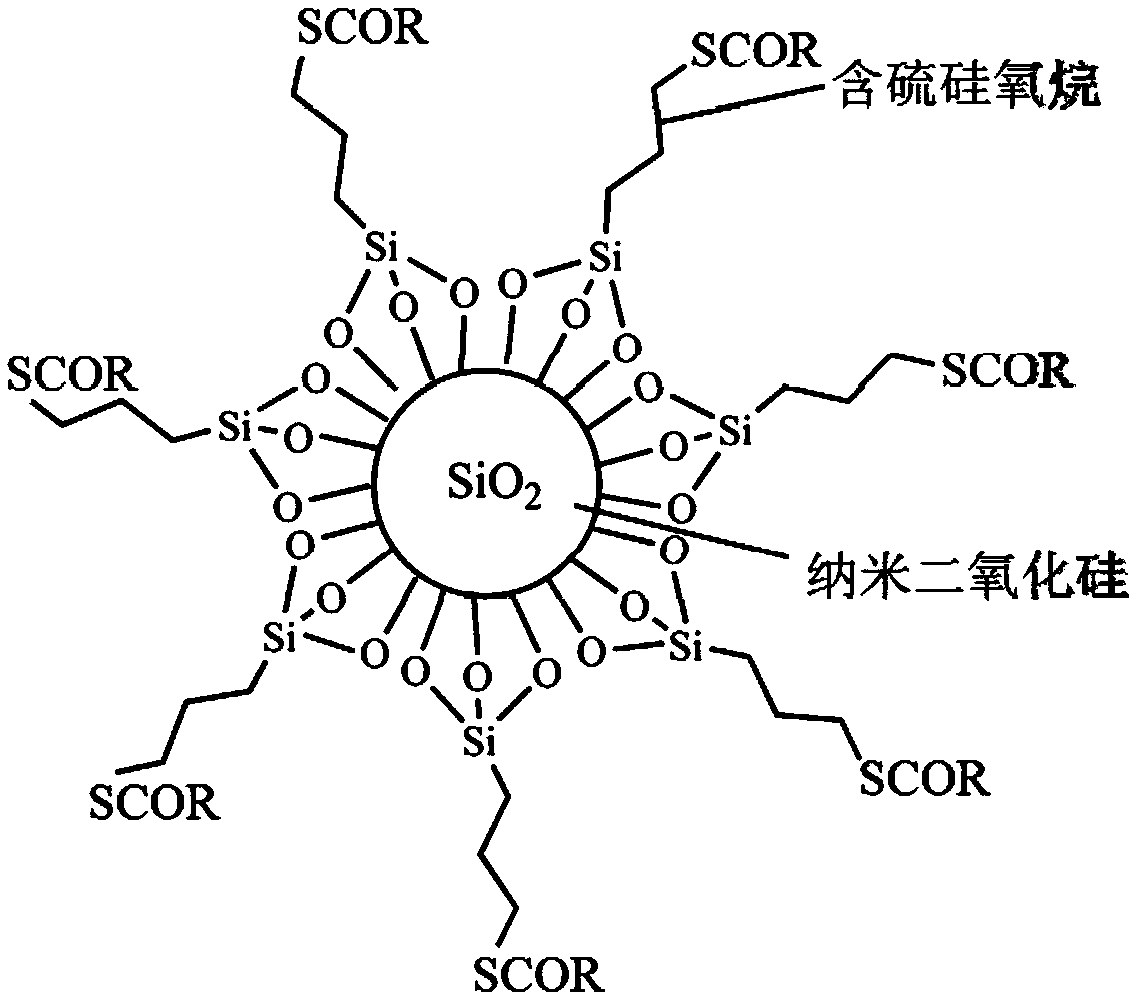

Modified sulfur-containing nano-silicon dioxide reinforced cable insulating layer material and application thereof

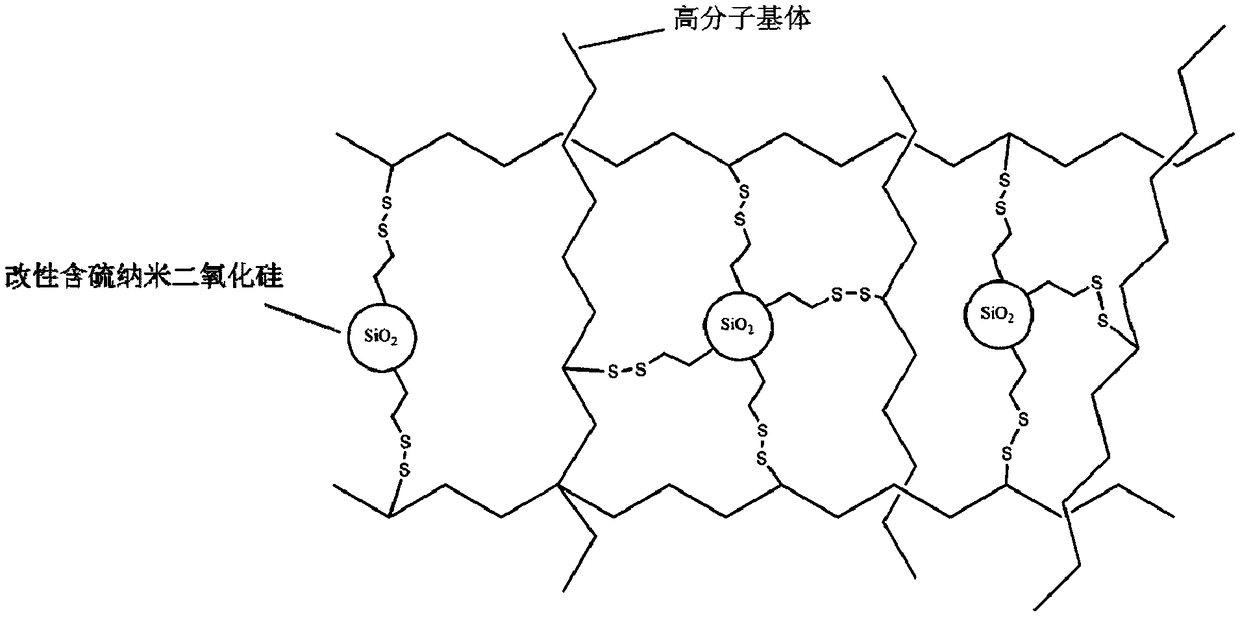

A nano-silica and insulating layer technology, applied in rubber insulators, organic insulators, etc., can solve the problems of affecting the reinforcement effect of silica particles, difficulty in uniform dispersion of silica particles, and poor dispersion, so as to improve mechanical properties and Insulation performance, enhanced reinforcement effect, strong mobility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

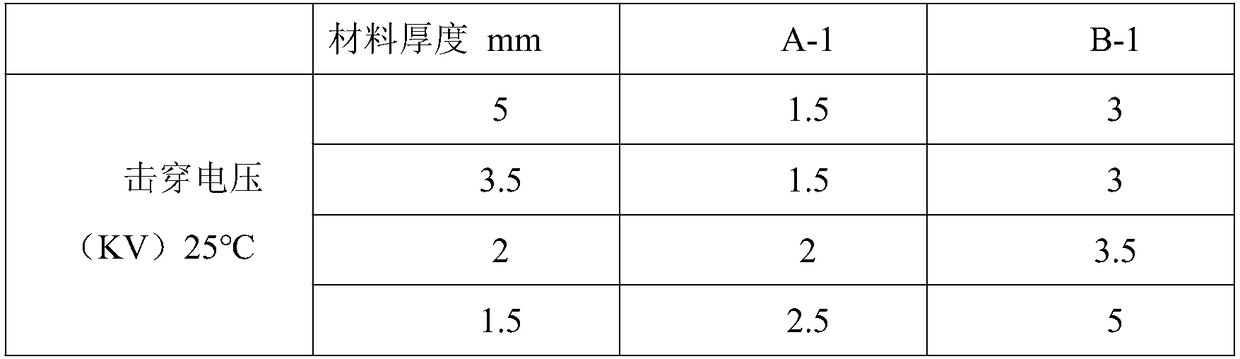

[0033] A modified sulfur-containing nano-silicon dioxide-reinforced cable insulation layer material, the raw materials of which include, in parts by weight, 100 parts by weight of butyl rubber, 10 parts by weight of modified sulfur-containing nano-silicon dioxide, and 6 parts by weight of oxidized polyethylene wax. Parts by weight, 11 parts by weight of carbon black, 0.5 parts by weight of antioxidant 4010NA (N-isopropyl-N'-phenyl-p-phenylenediamine).

[0034] Preparation of modified sulfur-containing nano-silica:

[0035] Add 50mL of absolute ethanol and 25mL of deionized water into the three-necked flask, add dropwise ammonia water until the pH is 10, and after the solution is evenly stirred, slowly add tetraethyl orthosilicate (TEOS) which accounts for 8% volume fraction of the solvent volume dropwise, React at room temperature for 3 h, then add N-methylpyrrolidone solution containing bis(triethoxysilylpropyl) tetrasulfide in a volume fraction of 2% by volume of the solvent...

Embodiment 2

[0044] A modified sulfur-containing nano-silicon dioxide-reinforced cable insulation layer material, the raw materials of which include, in parts by weight, 100 parts by weight of silicone rubber, 8 parts by weight of modified sulfur-containing nano-silicon dioxide, and 10 parts by weight of oxidized polyethylene wax Parts, 12 parts by weight of carbon black, 1 part by weight of antioxidant titanium dioxide;

[0045] The specific preparation steps of modified sulfur-containing nano-silica are as follows:

[0046] (1) 7.2 parts by weight of nano-silica (5nm particle size) is placed in a beaker, and then adding a molar concentration of 0.5mmol / L sodium hydroxide solution to it to form a density of 1g / L nano-silica solution; then the nano-silica solution was sonicated for 10 minutes, centrifuged to collect the precipitate, washed with water three times until neutral, and dried at 40°C.

[0047] (2) Add N-methylpyrrolidone to 90 parts by weight of nano-silica treated in step (1) ...

Embodiment 3

[0056] A modified sulfur-containing nano-silicon dioxide-reinforced cable insulation layer material, the raw materials of which include, in parts by weight, 100 parts by weight of styrene-butadiene rubber, 10 parts by weight of modified sulfur-containing nano-silicon dioxide, and 8 parts by weight of oxidized polyethylene wax. parts by weight, 15 parts by weight of carbon black, and 0.6 parts by weight of antioxidant titanium dioxide.

[0057] The specific preparation steps of modified sulfur-containing nano silicon dioxide are as follows:

[0058] Dissolve tetraethyl orthosilicate with a volume fraction of 4% of the total volume in a mixed solution of 50 mL xylene and 10 mL acetonitrile to prepare a precursor solution with a concentration of 0.5 mol / L, react at room temperature for 3 to 4 hours, and then add After adding bis(triethoxysilylpropyl) disulfide accounting for 2% volume fraction of the solvent volume, inject the precursor solution into the syringe pump, and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com