Biocatalyst for production of d-lactic acid

A technology of lactic acid and production method, applied in D-lactic acid production, effective D-lactic acid production, microorganisms producing D-lactic acid, high-efficiency production of high-purity lactic acid, D-lactic acid production field, can solve aspA inactivation, Difficult to decompose aspartic acid or glutamine, research on the production of fumaric acid, etc., to achieve the effect of reducing the content of pyruvate, inhibiting by-products, and reducing purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

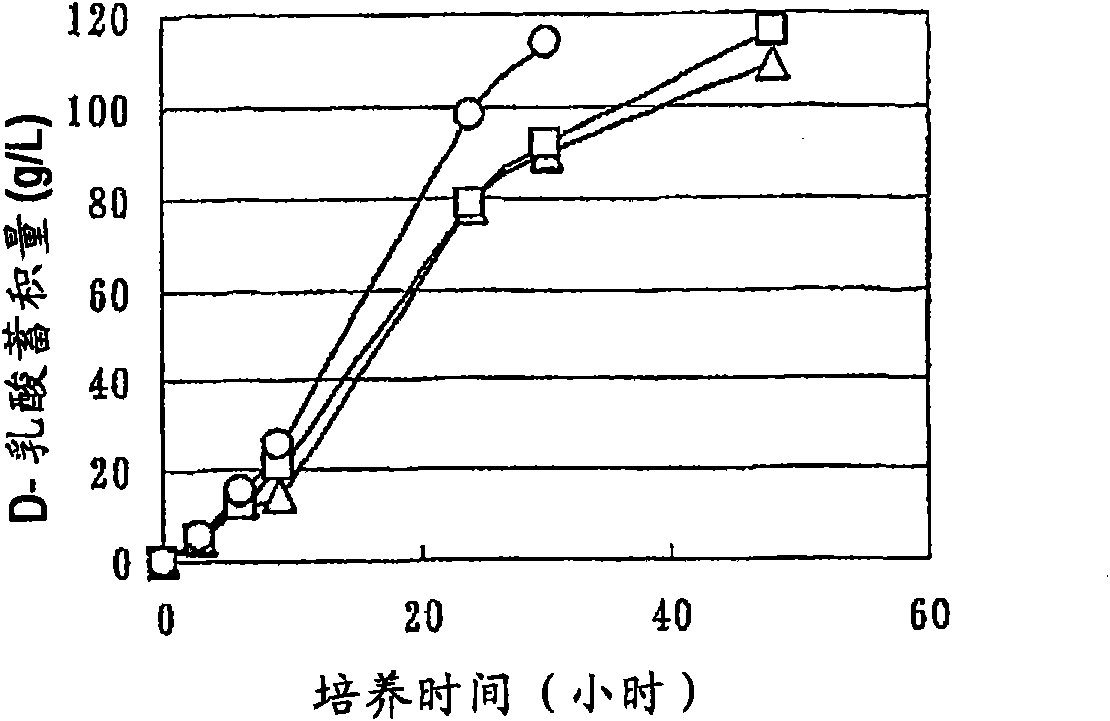

[0130] [Example 1] Utilize MT-10364 bacterial strain to produce lactic acid

[0131] The composition of the medium used for the culture is shown in Table 1 below.

[0132] Table 1

[0133]

[0134] This culture medium contains 0.34% of reducing sugar derived from grain extract after acid hydrolysis, 0.31% of D-lactic acid, 0.31% of L-lactic acid, 0.33% of free amino acid and trace amounts of various organic acids.

[0135] As pre-cultivation, 25ml LB Broth, Miller culture solution (Difco244620) was installed in the Erlenmeyer flask to carry out the planting of Escherichia coli MT-10934, stirred and cultivated overnight at a speed of 120rpm, and then cultured in 475g of the above-mentioned composition In a culture tank with a volume of 1 L (manufactured by ABLE Corporation, BMJ-01), the whole amount of bacteria was planted. Under the conditions of atmospheric pressure, aeration rate of 0.5vvm, stirring speed of 150rpm, culture temperature of 31°C, and pH of 6.7 (adjusted w...

Embodiment 2

[0141] [Example 2] Construction of ldhA expression vector and lactic acid producing bacteria

[0142] In order to obtain the promoter of serine hydroxymethyl transferase (glyA), the genomic DNA of Escherichia coli was used as a template, and sequence number 1 and sequence number 2 were used as probes to amplify by PCR method, and use restriction The resulting fragment was cut with endonuclease EcoRI, thereby obtaining a fragment encoding the glyA promoter of about 850 bp. Moreover, in order to obtain the structural gene of ldhA, the genomic DNA of Escherichia coli was used as a template, and sequence number 3 and sequence number 4 were used as probes to amplify by PCR method and cut with restriction enzymes EcoRI and HindIII The obtained fragment, thereby obtaining a ldhA structural gene fragment of about 1.0 kbp. The above two fragments were mixed with the fragment obtained by cutting plasmid pUC18 with restriction enzymes EcoRI and HindIII, ligated with DNA ligase, and then...

Embodiment 3

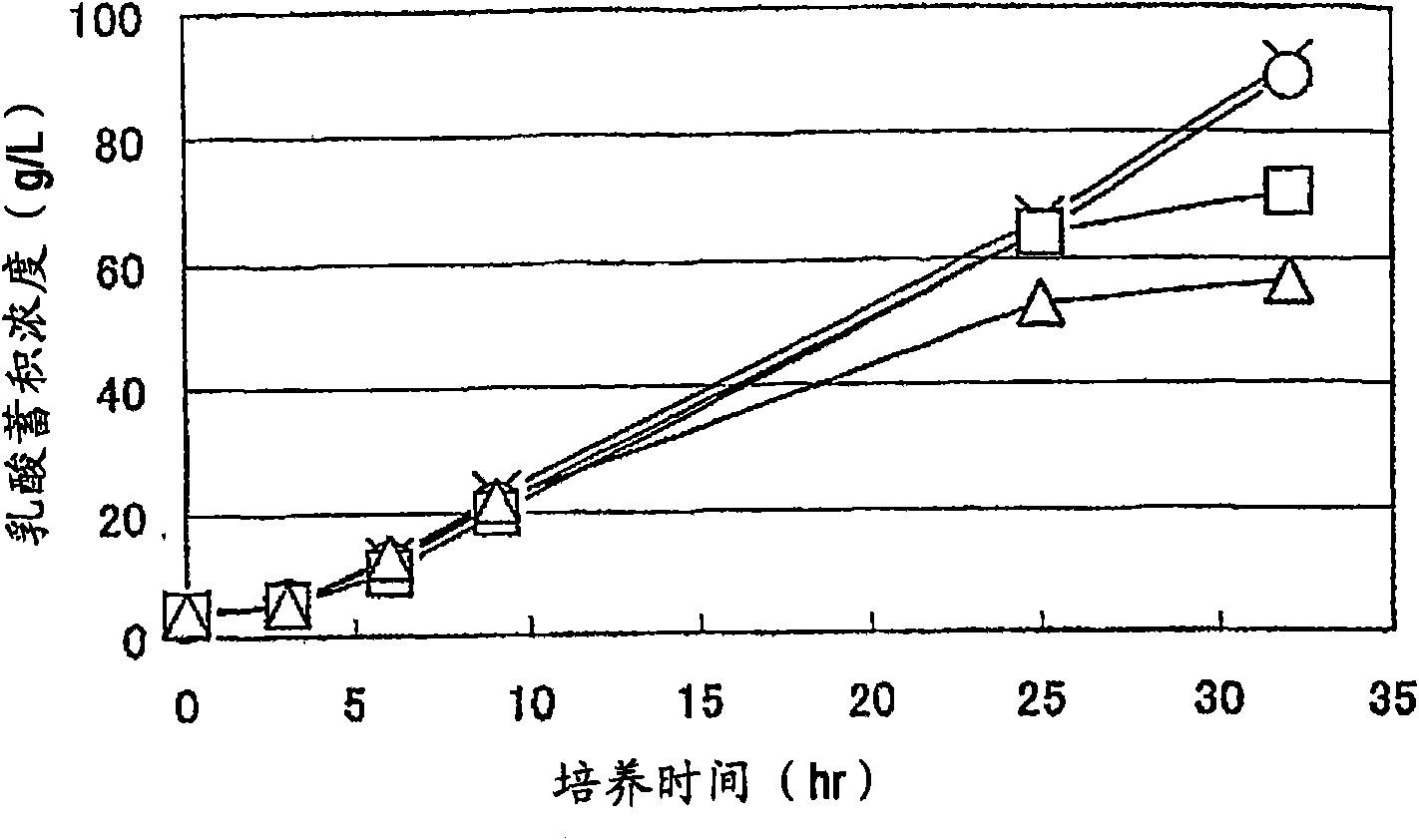

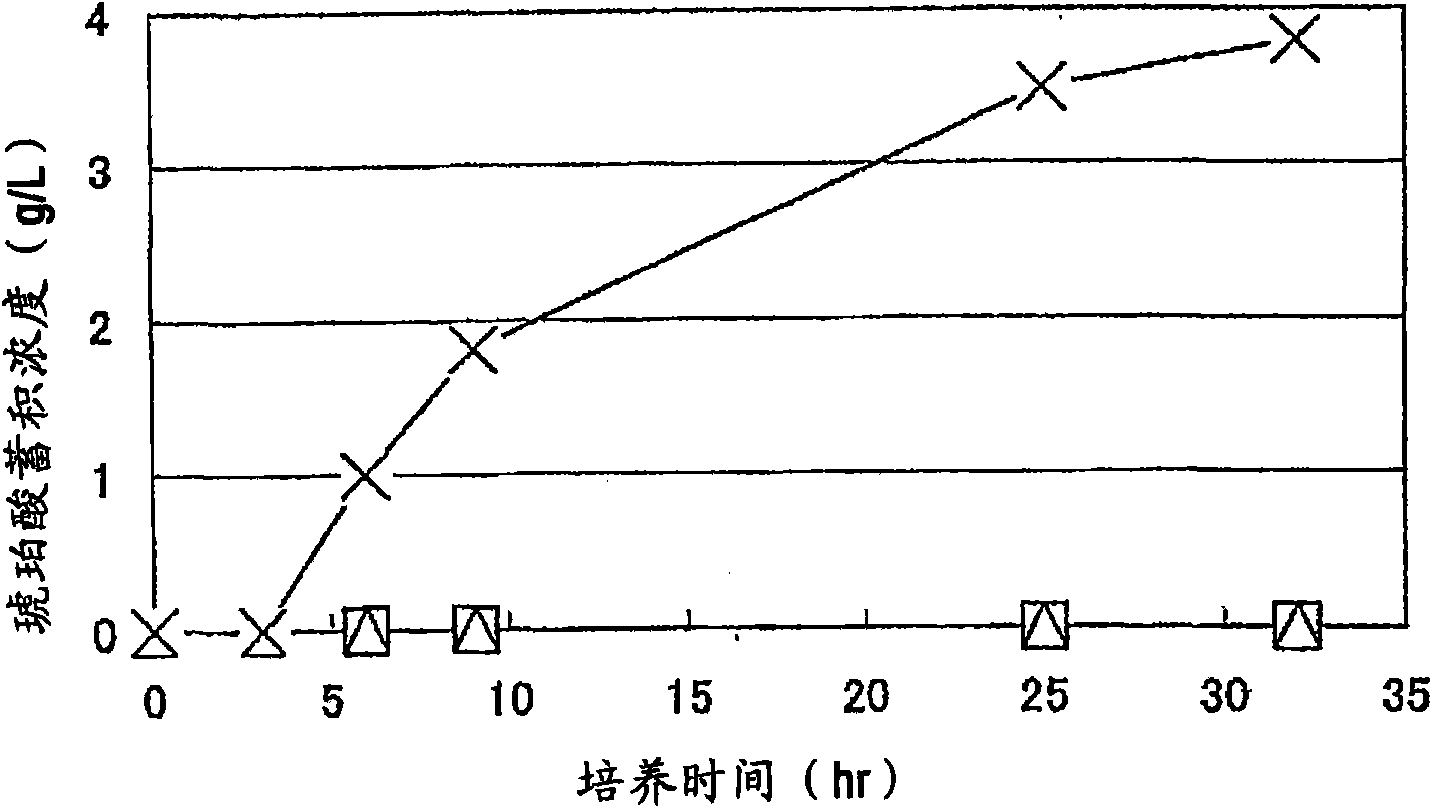

[0145] [Example 3] Lactic acid production by lactic acid-producing bacteria MT-10934 / pGlyldhA strain

[0146] As pre-cultivation, carry out the planting of the lactic acid producing bacteria MT-10934 / pGlyldhA bacterial strain obtained in Example 2 in an Erlenmeyer flask equipped with 25ml LB Broth, Miller culture solution (Difco244620), and utilize the same method as Example 1 to cultivate . After the cultivation, the content and optical purity of lactic acid were measured by HPLC according to conventional methods. The results are shown in Table 3.

[0147] table 3

[0148]

[0149] In the above results, the reason why the amount of total lactic acid exceeds the amount of glucose added at the beginning of the culture is that the carbon source in the grain extract was utilized. However, even if all the reducing sugars, organic acids, and amino acids in the grain extract are used, a conversion rate of 90% or more can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com