Low-temperature crushing and separating treatment method for oil field waste plastic

A technology of separation treatment and low-temperature crushing, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of exceeding national standards, polluting surface water and groundwater, etc., and achieve low operating costs, effective environmental protection, and resource utilization. The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

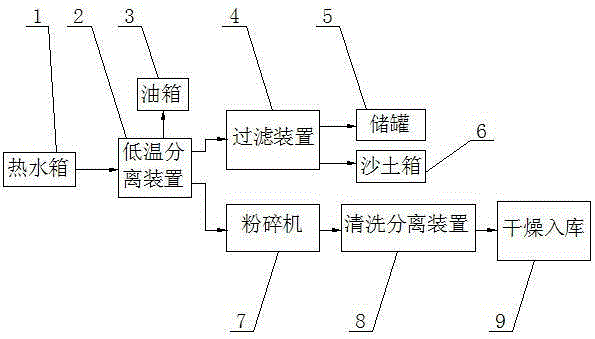

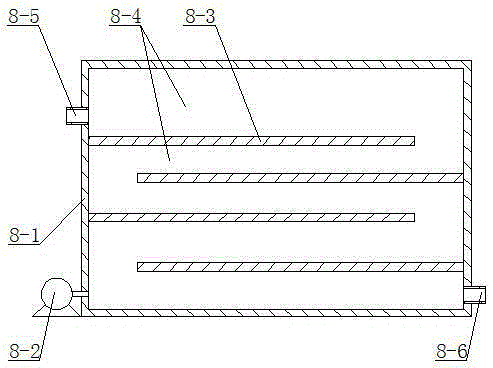

[0022] Specific implementation mode one: as Figure 1~Figure 3 As shown, the low-temperature pulverization and separation treatment method of oilfield waste plastics, the low-temperature pulverization and separation treatment method of oilfield waste plastics includes the following steps:

[0023] Step 1: pretreatment; arrange the sludge and waste plastics in the hot water tank 1 for initial cleaning, and the temperature of the hot water in the hot water tank 1 is 50-55°C;

[0024] The purpose is to refine and separate the sand and gravel in the waste plastic cloth sludge, and the extracted sewage has a low oil content, which can be directly discharged into the sewage treatment device for biochemical treatment.

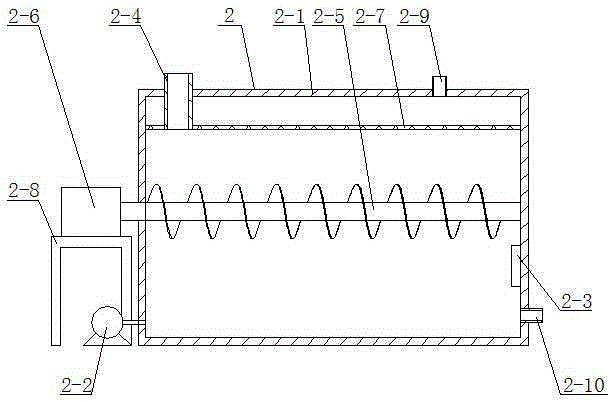

[0025] Step 2: low-temperature separation treatment; put the pretreated sludge waste plastic cloth into the low-temperature separation device 2, and simultaneously inject water into the low-temperature separation device 2 for oil-water separation, and the waste sludge...

specific Embodiment approach 2

[0035] Specific embodiment two: the low-temperature pulverization and separation treatment method of oil field waste plastics described in specific embodiment one. 25% (mass percentage) of alkanolamide, 0.2% (mass percentage) of sodium oleate, 3% (mass percentage) of sodium pyrophosphate, and the balance is composed of caustic soda, and all the above-mentioned raw materials are mixed in Together.

[0036]The feature of this cleaning aid is that it can quickly and effectively emulsify, disperse, and dissolve oil stains on waste plastic cloth, and it is non-toxic to washing materials and the environment, has no irritating odor, and does not pollute the environment.

specific Embodiment approach 3

[0037] Specific implementation mode three: the low-temperature pulverization and separation treatment method of oil field waste plastics described in specific implementation mode 1 or 2, the low-temperature separation treatment in step 2 is divided into two stages; in the first stage, the water temperature is 30~35°C, and the processing time is 20~ 25mim, the low-boiling light hydrocarbons on the waste sludge and waste plastic cloth volatilize from the oily sludge; in the second stage, when the water temperature is 36°C to 45°C, the heavy oil on the waste sludge and waste plastic cloth Initial partial separation; eventually four products of oil, water, waste plastic cloth and burnt sand (i.e. a small amount of debris) are separated.

[0038] This separation process consists of the following two stages:

[0039] Ⅰ Low-temperature separation stage: When the water temperature is 30-35°C, light hydrocarbons with low boiling points are volatilized from the oily sludge;

[0040] Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com