A kind of method that rare earth cerium chloride prepares cerium oxide

A technology of cerium chloride and cerium oxide, applied in rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of decreasing the purity of rare earth oxides, affecting the quality of rare earth oxides, uneven size distribution, etc. Generation of cerium oxychloride by-products, unique heat and mass transfer laws, time- and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

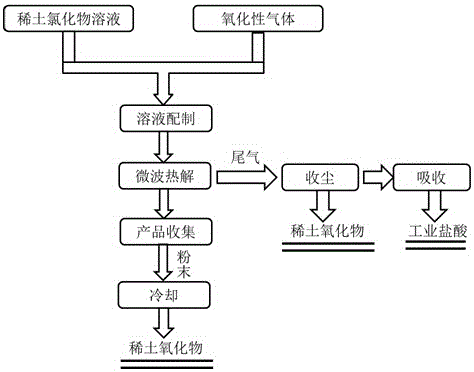

[0028] Such as figure 1 Shown, this rare earth cerium chloride prepares the method for cerium oxide, and its concrete steps are as follows: first configure the solution of the cerium chloride of 95g / L, then add dispersing agent according to solution volume percentage 5% (polyethylene glycol and ethanol according to mass ratio The mixture obtained by mixing uniformly at 10:1) is mixed uniformly to obtain a mixed solution, and the mixed solution is atomized into droplets, which are sprayed from the top of the microwave reactor (the blowing volume of the droplets is 30m 3 / h), the oxidizing gas is introduced from the bottom (the oxidizing gas is air, and the inflow rate is 1000m 3 / h), carry out microwave pyrolysis under negative pressure of 10000Pa (microwave pyrolysis temperature is 1500°C, pyrolysis time is 8 seconds), the reaction produces cerium oxide and tail gas, and the tail gas is dust-collected and absorbed to obtain industrial hydrochloric acid.

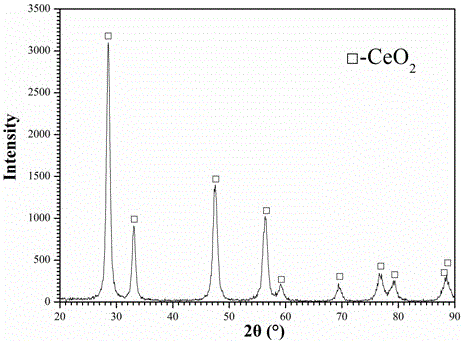

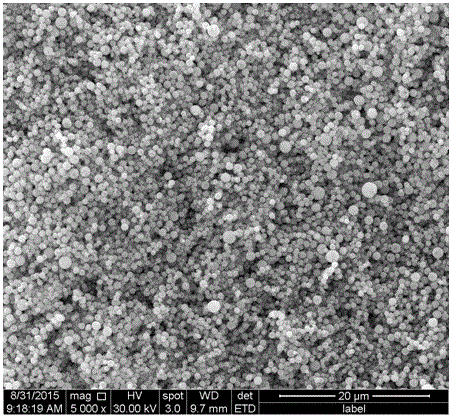

[0029] The cerium ox...

Embodiment 2

[0031] Such as figure 1 As shown, the method for preparing cerium oxide from the rare earth cerium chloride, its specific steps are as follows: first configure the solution of 2g / L cerium chloride, and then add a dispersant according to the volume percentage of the solution at 0.3% (polyethylene glycol and ethanol according to the mass ratio The mixture obtained by mixing uniformly at a ratio of 1:10) is mixed uniformly to obtain a mixed solution, and the mixed solution is atomized into droplets, which are sprayed from the top of the microwave reactor (the blowing volume of the droplets is 0.1m 3 / h), the oxidizing gas is introduced from the bottom (the oxidizing gas is oxygen, and the inflow rate is 50m 3 / h), carry out microwave pyrolysis under 100Pa negative pressure (microwave pyrolysis temperature is 700°C, and pyrolysis time is 0.5 seconds), the reaction produces cerium oxide and tail gas, and the tail gas is dust-collected and absorbed to obtain industrial hydrochloric ...

Embodiment 3

[0034] Such as figure 1 Shown, this rare earth cerium chloride prepares the method for cerium oxide, and its specific steps are as follows: first configure the solution of the cerium chloride of 10g / L, then add dispersing agent according to the volume percentage in the solution (polyethylene glycol and ethanol according to mass The ratio is 1:5 and the mixture obtained by mixing uniformly) is mixed uniformly to obtain a mixed solution, and the mixed solution is atomized into droplets, which are sprayed from the top of the microwave reactor (the blowing volume of the droplets is 1m 3 / h), the oxidizing gas is introduced from the bottom (the oxidizing gas is oxygen-enriched, and the inflow rate is 100m 3 / h), carry out microwave pyrolysis under 1000Pa negative pressure (microwave pyrolysis temperature is 900°C, and pyrolysis time is 2 seconds), the reaction produces cerium oxide and tail gas, and the tail gas is dust-collected and absorbed to obtain industrial hydrochloric acid....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com