A kind of industrial solid waste and non-metallic tailings block for mineral wool production and preparation method thereof

An industrial solid waste, non-metal technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of low strength, high production cost of mineral wool, and low recycling rate of industrial solid waste, etc. Achieve performance improvement such as strength, reduce waste output, and have no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

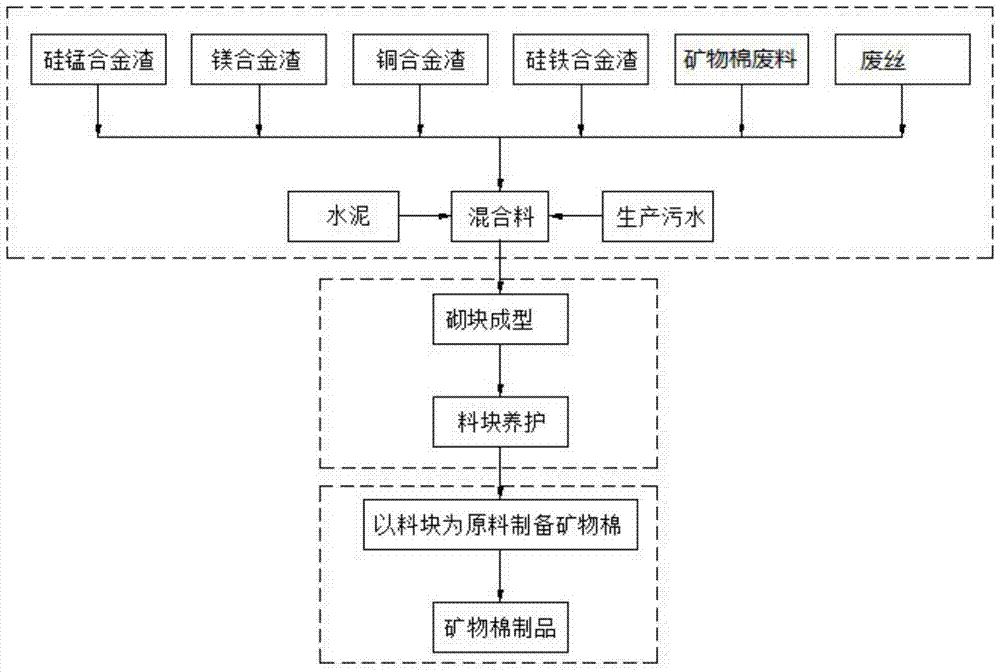

Method used

Image

Examples

Embodiment 1

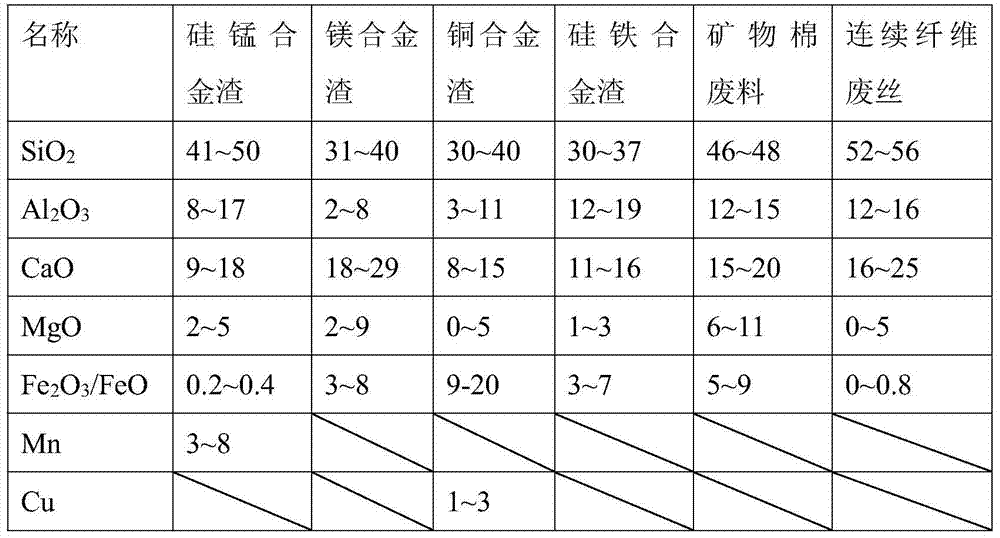

[0033] The raw materials of industrial solid waste and non-metallic tailings for mineral wool production include: 25 parts of silicon-manganese alloy slag, 20 parts of magnesium alloy slag, 10 parts of copper alloy slag, 5 parts of ferrosilicon alloy slag, and 10 parts of mineral wool waste , 20 parts of waste silk, 10 parts of cement and 9 parts of water, the parts are parts by mass.

Embodiment 2

[0035] The raw materials of industrial solid waste and non-metallic tailings for mineral wool production include: 30 parts of silicon-manganese alloy slag, 20 parts of magnesium alloy slag, 10 parts of copper alloy slag, 12 parts of ferrosilicon alloy slag, and 18 parts of mineral wool waste , waste silk is 0 parts, cement 10 parts and water 10 parts, and described parts are mass parts.

Embodiment 3

[0037] The raw materials of industrial solid waste and non-metallic tailings for mineral wool production include: 30 parts of silicon-manganese alloy slag, 16 parts of magnesium alloy slag, 15 parts of copper alloy slag, 14 parts of ferrosilicon alloy slag, and 0 parts of mineral wool waste , 20 parts of waste silk, 5 parts of cement and 5 parts of water, the parts are parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com