Composite microbial straw decomposing agent and preparation method thereof

A straw decomposing agent and compound microorganism technology, applied in the field of microorganisms, can solve problems affecting the normal operation of aviation, railways and expressways, affecting the yield and quality of farmland crops, and affecting the full absorption of soil nutrients, so as to achieve sustainable development and enhance Plant stress resistance, effect of improving crop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

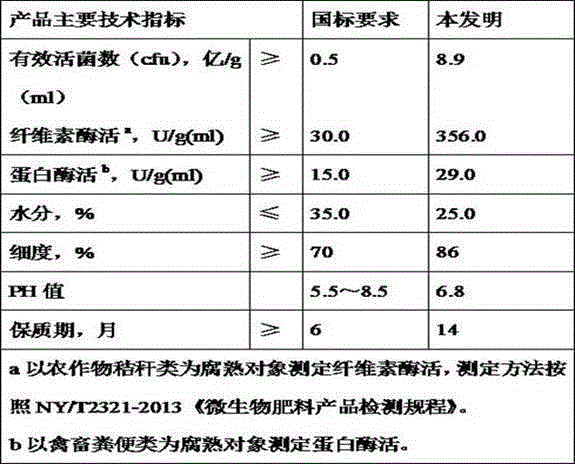

Embodiment 1

[0025] A preparation method of a composite microorganism straw decomposing agent, comprising the following steps:

[0026] Step 1. Prepare nutrient solution

[0027] 700g of molasses with a sugar content of 75° and 5000g of demineralized water are mixed and evenly prepared to form a nutrient solution;

[0028] Step two, compound inoculation

[0029] Adjust the temperature of the nutrient solution to 37°C, sequentially inoculate 25g of Bacillus natto, 25g of Lactobacillus plantarum, 25g of Bacillus colioids, 60g of Trichoderma viride, and 150g of yeast into the nutrient solution, and Bacillus natto, plant The number of live bacteria of Lactobacillus, Bacillus colloid, Trichoderma viride, and yeast is 500-1000 million per gram;

[0030] Step 3: Sealed constant temperature fermentation

[0031] Adjust the temperature of the nutrient solution after inoculation to 37°C, seal and ferment at constant temperature for 6 days;

[0032] Step 4, secondary fermentation

[0033] Take 6...

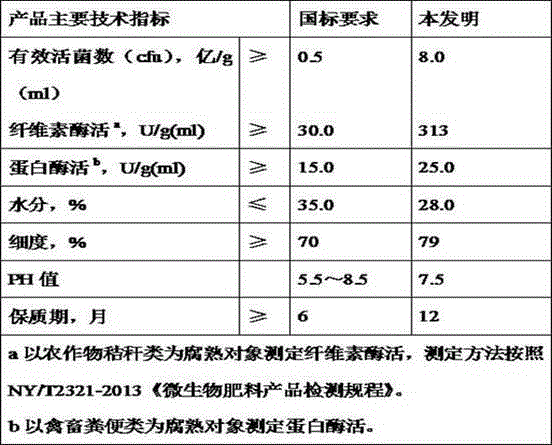

Embodiment 2

[0038] A preparation method of a compound microbial straw decomposing agent, comprising the following steps:

[0039] Step 1. Prepare nutrient solution

[0040] 800g of molasses with a sugar content of 75° and 5000g of demineralized water are mixed and evenly prepared to form a nutrient solution;

[0041] Step two, compound inoculation

[0042] Adjust the temperature of the nutrient solution to 37°C, sequentially inoculate 30g of Bacillus natto, 30g of Lactobacillus plantarum, 30g of Bacillus colioids, 80g of Trichoderma viride, and 200g of yeast into the nutrient solution, and Bacillus natto, plant The number of live bacteria of Lactobacillus, Bacillus colloid, Trichoderma viride, and yeast is 500-1 billion per gram;

[0043] Step 3: Sealed constant temperature fermentation

[0044] Adjust the temperature of the nutrient solution after inoculation to 37°C, seal and ferment at constant temperature for 6 days;

[0045] Step 4, secondary fermentation

[0046] Take 5000g of ...

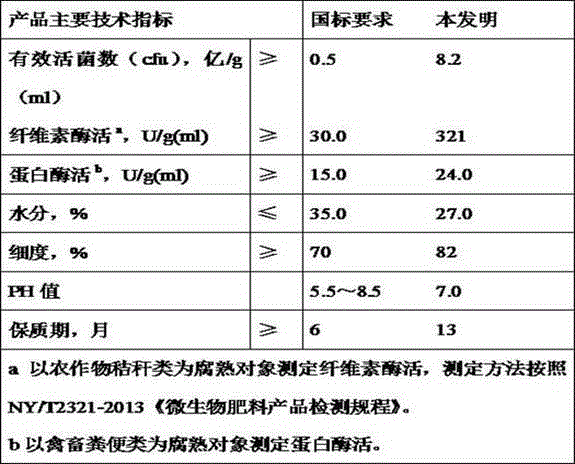

Embodiment 3

[0050] A preparation method of a compound microbial straw decomposing agent, comprising the following steps:

[0051] Step 1. Prepare nutrient solution

[0052] 500g of molasses with a sugar content of 75° and 4000g of demineralized water are mixed and evenly prepared to form a nutrient solution;

[0053] Step two, compound inoculation

[0054]Adjust the temperature of the nutrient solution to 37°C, sequentially inoculate 20g of Bacillus natto, 20g of Lactobacillus plantarum, 20g of Bacillus colioids, 50g of Trichoderma viride, and 100g of yeast into the nutrient solution, and Bacillus natto, plant The number of live bacteria of Lactobacillus, Bacillus colloid, Trichoderma viride, and yeast is 500-1000 million per gram;

[0055] Step 3: Sealed constant temperature fermentation

[0056] Adjust the temperature of the nutrient solution after inoculation to 37°C, seal and ferment at constant temperature for 6 days;

[0057] Step 4, secondary fermentation

[0058] Add 6000g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com