Nanometer inorganic zinc-rich composite anticorrosive coating and preparation method thereof

A nano-inorganic, anti-corrosion coating technology, used in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc. It is easy to industrialize large-scale production, improve scratch and corrosion resistance, and has strong bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] And in a more specific preferred implementation case, the preparation method of described nano-modified polyaniline can comprise:

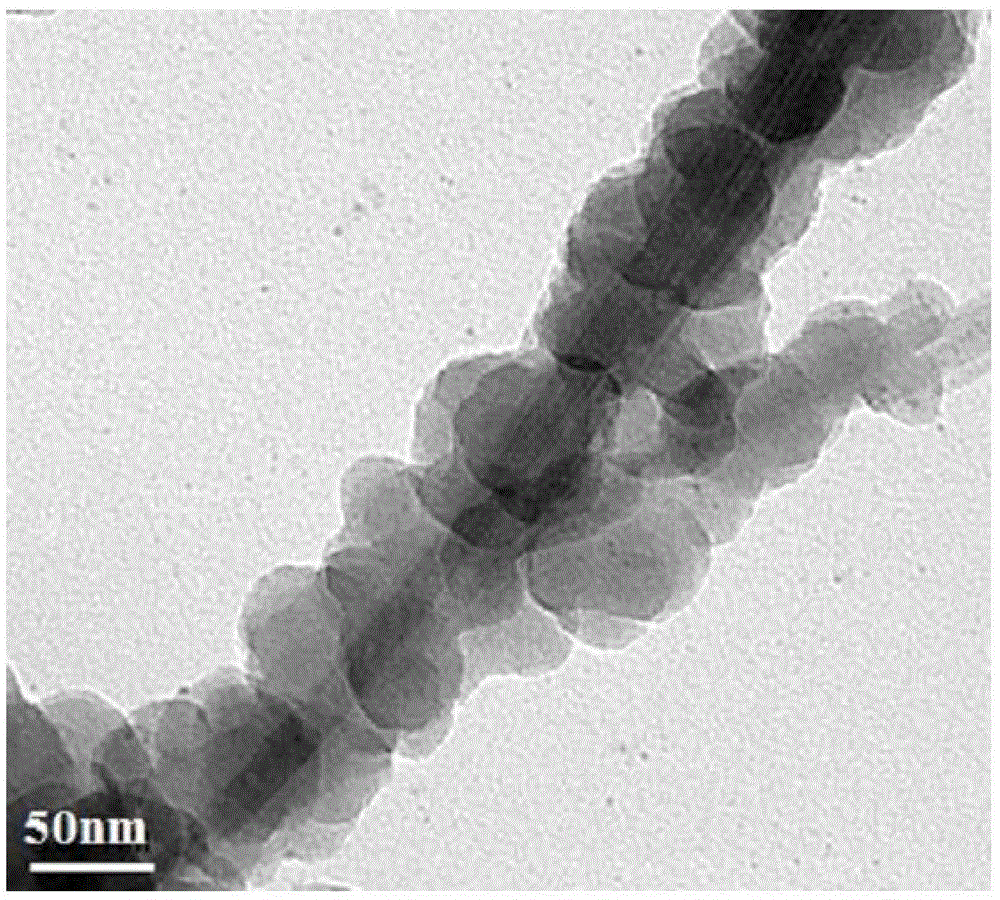

[0044] Under the condition that the stirring speed is not lower than 1000 rev / min, the nano-attapulgite and aniline with a diameter of 20nm to 50nm and a length of 0.5μm to 3μm are added to water and mixed to form a suspension.

[0045] Under the condition of continuous stirring, add a surface modifier and a dopant to the suspension, and then slowly add an oxidant, filter after the reaction, take the filtrate to wash and dry, and obtain the nano-modified polyaniline.

[0046] Wherein, the surface modifier may be at least selected from cetyltrimethylammonium bromide or dodecyltrimethylammonium bromide, and is not limited thereto.

[0047]Wherein, the dopant may be at least selected from camphorsulfonic acid or sulfosalicylic acid, and is not limited thereto.

[0048] Wherein, the oxidizing agent may be ammonium persulfate, but is not limite...

Embodiment 1

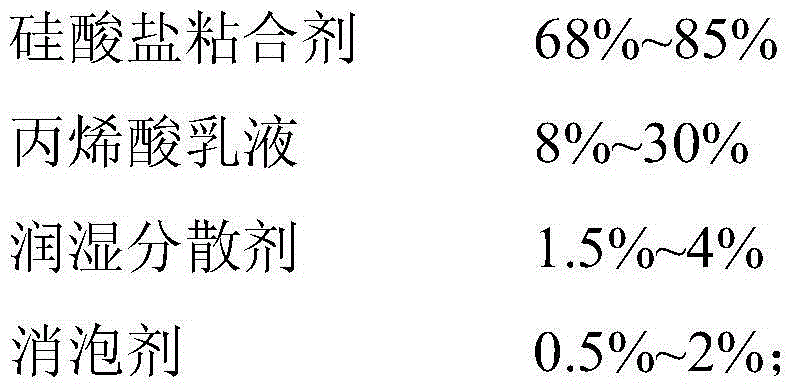

[0069] 1) Take 85 grams of potassium silicate-sodium silicate solution with a modulus of 3.5, add 13 grams of pure acrylic emulsion, 2 grams of wetting and dispersing agent and 1 gram of defoamer, stir to make it completely dispersed, and make Group A Minute;

[0070] 2) Add 8 grams of nano-modified polyaniline to the above-mentioned component A solution, stir for 1.5 hours at 1000 rpm to disperse the nano-modified polyaniline evenly in the liquid, and finally add 292 grams of 500-mesh flake zinc powder, the mass ratio of component A and component B is 1:3, and keep stirring for 30 minutes to obtain nano inorganic zinc-rich composite anticorrosion coating.

[0071] The nano inorganic zinc-rich composite anti-corrosion paint of this embodiment was sprayed on the tinplate substrate treated with sandpaper and the iron plate treated with sandblasting by high-pressure air spraying. After being completely cured, the coating film sample Y1 was obtained. Reserved for performance eva...

Embodiment 2

[0073] 1) Take 80 grams of potassium silicate solution with a modulus of 4.0, add 14 grams of styrene-acrylic emulsion, 2.5 grams of wetting and dispersing agent and 1.5 grams of defoamer, stir to make it completely dispersed, and make component A.

[0074] 2) Add 10 grams of nano-modified polyaniline to the above-mentioned component A solution, stir for 1.5 hours at 1000 rpm to disperse the nano-modified polyaniline evenly in the liquid, and finally add 290 grams of 600-mesh flake zinc powder, the mass ratio of component A and component B is 1:3, and keep stirring for 30 minutes to obtain nano inorganic zinc-rich composite anticorrosion coating.

[0075] The nano inorganic zinc-rich composite anti-corrosion paint of this embodiment was sprayed on the tinplate substrate treated with sandpaper and the iron plate treated with sandblasting by high-pressure air spraying. After being completely cured, the coating film sample Y2 was obtained. Reserved for performance evaluation tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com