Deodorization insole and preparation method thereof

An insole and anti-odor technology, which is applied in the field of shoe lining materials, can solve the problems of impact on the use effect, poor perspiration function, and inability to adapt to market demand, etc., and achieve the effect of convenient operation, strong perspiration function, and easy production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

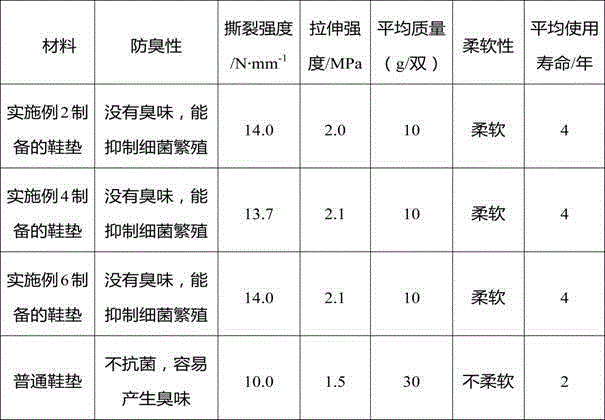

Examples

Embodiment 1

[0030] A kind of deodorant insole

[0031] Deodorant insole raw material composition:

[0032] 3.5kg of cinnamon oil, 7kg of monkshood oil, 3.5kg of paraben, 7kg of benzoic acid, 3.15kg of zeolite, 6.3kg of titanium dioxide, 3.1kg of zinc oxide, 1.1kg of EVA, 20kg of polyethylene, 20kg of polypropylene, 13kg of artificial rubber, polyurethane 13kg.

Embodiment 2

[0034] A kind of preparation method of deodorant insole

[0035] The specific steps are:

[0036] (1) Pulverization: Ultrafine pulverization of zeolite, titanium dioxide, and zinc oxide until the particle size is 20nm.

[0037] (2) Base material preparation: Melt EVA, polyethylene, polypropylene, artificial rubber, and polyurethane at a vacuum of 0.01MPa and 200°C for 20 minutes, and stir at a speed of 20r / min for 10 minutes until the material is uniform .

[0038] (3) Preliminary mixing: Add the pulverized zeolite, titanium dioxide, and zinc oxide to the prepared base material, keep warm at 180°C under 1 atmospheric pressure, stir at a speed of 20r / min for 10 minutes, and stir evenly to obtain a preliminary mixture.

[0039] (4) Secondary mixing: add cinnamon oil, luohan cedar oil, paraben ester, and benzoic acid to the primary mixture, and keep it warm at 190°C under an atmospheric pressure, and stir at a speed of 2000r / min for 10 minutes to obtain secondary mix.

[0040...

Embodiment 3

[0042] A kind of deodorant insole

[0043] Deodorant insole raw material composition:

[0044] The parts by weight of the organic antibacterial material consist of: cassia bark oil 6kg, Luo Han tar 8kg, paraben 6kg, benzoic acid 12kg, zeolite 6.4kg, titanium dioxide 7.2kg, zinc oxide 2.4kg, EVA6kg, polyethylene 30kg, polypropylene 30kg , Artificial rubber 15kg, polyurethane 15kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com