Reaction and rectification device and method for producing isopropanolamine

A technology of isopropanolamine and reactive distillation, applied in separation methods, chemical instruments and methods, fractional distillation, etc., can solve the problems of low efficiency, cumbersome process steps of isopropanolamine, high energy consumption, etc., and achieve reduction of total investment, The reaction process is stable and controllable, and the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

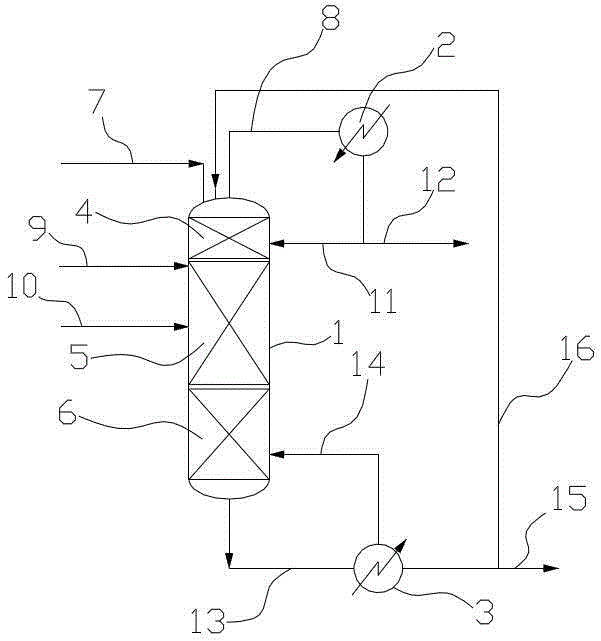

[0024] Such as figure 1 A reactive distillation device for producing isopropanolamine is shown, the reactive distillation device includes a reactive distillation tower 1, a condenser 2 and a reboiler 3, and the reactive distillation tower is divided into a rectification section 4 from top to bottom , the reaction section 5 and the stripping section 6, the top of the reactive distillation column is provided with a water inlet pipe 7 and a condenser feed pipe 8, and the condenser feed pipe is connected with the condenser inlet, and the condenser outlet is connected with the rectification section. The distillate reflux pipe 11 and the tower top product discharge pipe 12, the upper part of the reaction section is provided with an ammonia feed pipe 9, the middle part of the reaction section is provided with a propylene oxide feed pipe 10, and the bottom of the reactive distillation tower passes through the connecting pipe 13 is connected with the inlet of the reboiler, the top of t...

Embodiment 2

[0027] The reaction rectification device of producing isopropanolamine in the present embodiment and embodiment 1 figure 1 Exactly the same, the difference lies in the process parameters in the method for producing isopropanolamine, specifically: ammonia water, propylene oxide are charged according to the ratio that the molar ratio of ammonia to propylene oxide is 1, and the feeding of ammonia water and propylene oxide is controlled. The material temperature is 250°C; the temperature at the top of the reaction distillation tower is controlled at 50°C, the temperature of the reaction section is 300°C, the temperature at the bottom of the reaction distillation tower is 200°C, and the operating pressure of the entire column of the reaction distillation tower is 50 bar; The molar ratio of internal ammonia to propylene oxide was 30.

Embodiment 3

[0029] The reaction rectification device of producing isopropanolamine in the present embodiment and embodiment 1 figure 1 Exactly the same, the difference lies in the process parameters in the method for producing isopropanolamine, specifically: ammonia water, propylene oxide are charged according to the ratio that the molar ratio of ammonia to propylene oxide is 1.1, and the feeding of ammonia water and propylene oxide is controlled. The material temperature is 300°C; the temperature at the top of the reactive distillation tower is controlled to be 101°C, the temperature of the reaction section is 350°C, the temperature at the bottom of the reactive distillation tower is 240°C, and the operating pressure of the entire column of the reactive distillation tower is 100 bar; The molar ratio of internal ammonia to propylene oxide was 300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com