Methanol water reforming hydrogen production machine and hydrogen production method thereof

A methanol water and hydrogen generator technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as waste of heat energy, adverse noise reduction, adverse effects, etc., and achieve the effect of ensuring work stability and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

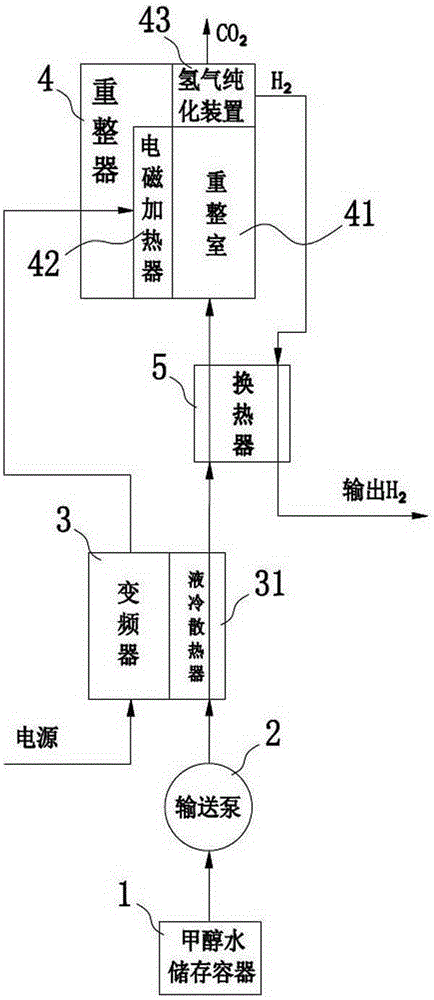

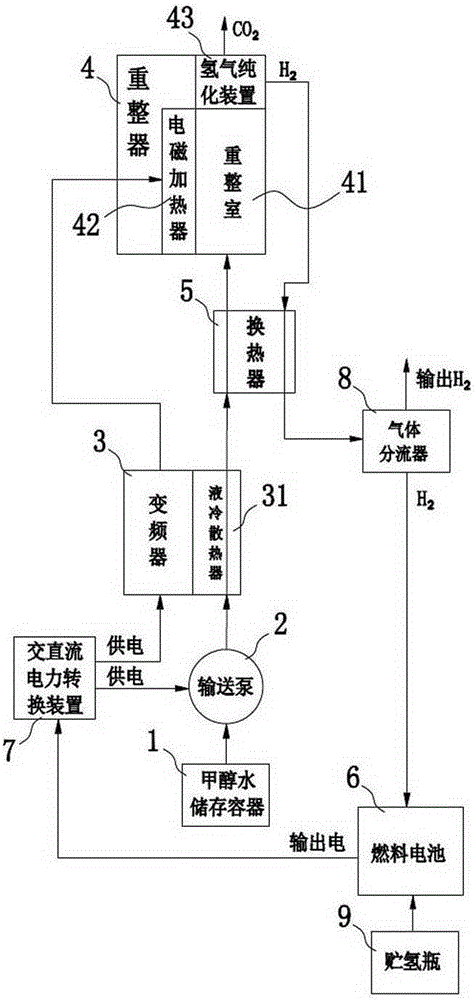

[0031] like figure 1 As shown, the present invention is a methanol-water reforming hydrogen generator, comprising a methanol-water storage container 1, a transfer pump 2, a frequency converter 3, a heat exchanger 5 and a reformer 4, wherein:

[0032] Methanol-water storage container 1, which stores liquid methanol-water raw material;

[0033] The delivery pump 2 is used to pump the methanol water raw material in the methanol water storage container 1 to the reforming chamber 41 of the reformer 4 through the delivery pipeline;

[0034] The frequency converter 3 is used to convert the low-frequency voltage or DC voltage into the high-frequency voltage required by the electromagnetic coil 421 of the electromagnetic heater 42. The frequency converter 3 is provided with a liquid-cooled radiator 31, and the methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com