Method for preparing high-grade artificial rutile from high-calcium and high-magnesium rock-mineral ilmenite

A technology of artificial rutile and ilmenite, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of equipment corrosion, difficult removal of calcium and magnesium, high energy consumption, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

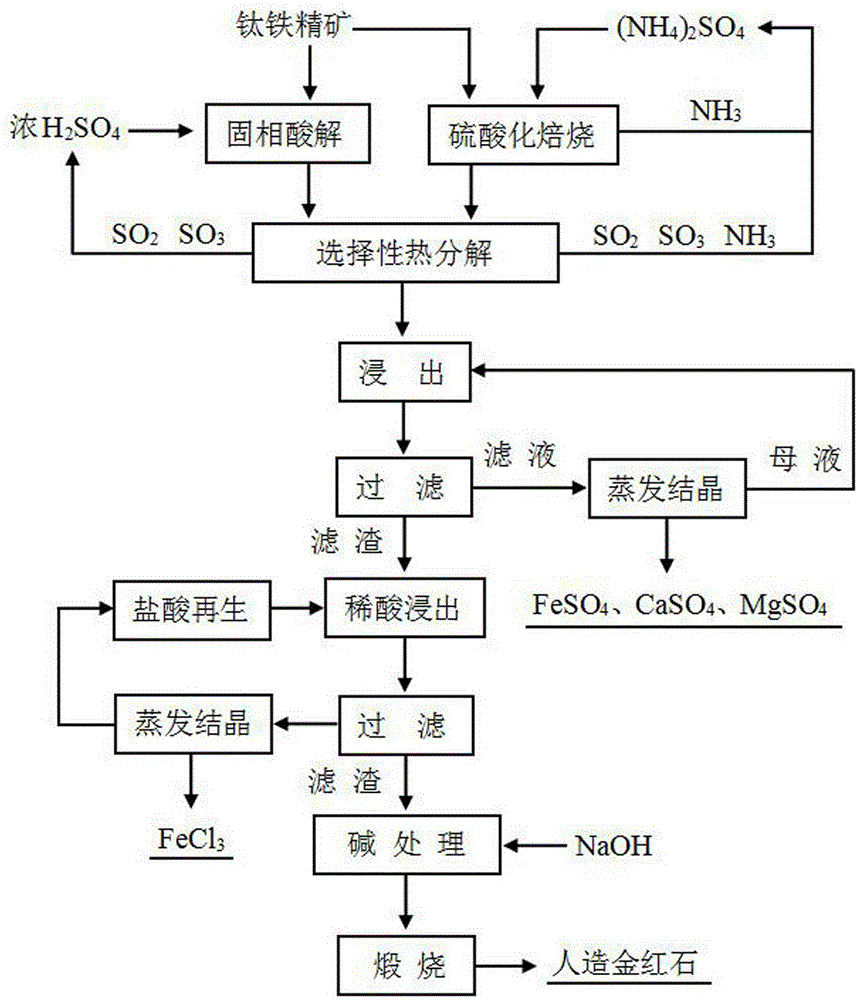

Method used

Image

Examples

Embodiment 1

[0031] (1) Finely ground ilmenite concentrate below 50 μm with ammonium sulfate ((NH 4 ) 2 SO 4 ) are uniformly mixed, and the mass ratio of ilmenite concentrate and ammonium sulfate is controlled to be 1:14.

[0032] (2), put the mixture obtained in step (1) into the tube furnace, ° C / min heating up to 250 ° C and keep warm for 240min. After the reaction finished, continue to feed the material with 10 ° C / min rises to 430°C with the furnace and keeps the temperature for 240min. After the reaction was over, the material was taken out and cooled to room temperature naturally to obtain a massive solid.

[0033] (3), leaching the massive solid obtained in step (2) with water, and controlling the leaching temperature to 90 ° C The reaction time is 10 minutes, and the liquid-solid mass ratio is 3:1. After the reaction, the solution was cooled to room temperature and filtered to obtain a filter residue.

[0034] (4), the filter residue obtained in the step (3), is leached w...

Embodiment 2

[0037] (1) Finely ground ilmenite concentrate below 50 μm with ammonium sulfate ((NH 4 ) 2 SO 4 ) are uniformly mixed, and the mass ratio of ilmenite concentrate and ammonium sulfate is controlled to be 1:5.

[0038] (2), put the mixture obtained in step (1) into the tube furnace, ° C / min heat up to 360 ° C and keep warm for 120min. After the reaction finished, continue to feed the material with 10 ° C / min rises with the furnace to 560°C and keeps it warm for 120min. After the reaction was over, the material was taken out and cooled to room temperature naturally to obtain a massive solid.

[0039] (3), leaching the massive solid obtained in step (2) with water, controlling the leaching temperature to be 40 ° C The reaction time is 90 minutes, and the liquid-solid mass ratio is 15:1. After the reaction, the solution was cooled to room temperature and filtered to obtain a filter residue.

[0040] (4), leaching the filter residue obtained in step (3) with a mass fraction...

Embodiment 3

[0043] (1) Finely ground ilmenite concentrate below 50 μm with ammonium sulfate ((NH 4 ) 2 SO 4 ) are uniformly mixed, and the mass ratio of ilmenite concentrate and ammonium sulfate is controlled to be 1:20.

[0044] (2), put the mixture obtained in step (1) into the tube furnace, ° C / min heat up to 420 ° C and keep warm for 60min. After the reaction finished, continue to feed the material with 10 ° C / min rises with the furnace to 650°C and keeps it warm for 60 minutes. After the reaction was over, the material was taken out and cooled to room temperature naturally to obtain a massive solid.

[0045] (3), leaching the massive solid obtained in step (2) with water, controlling the leaching temperature to be 40 ° C The reaction time is 50 minutes, and the liquid-solid mass ratio is 10:1. After the reaction, the solution was cooled to room temperature and filtered to obtain a filter residue.

[0046] (4), leaching the filter residue obtained in step (3) with a mass frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com