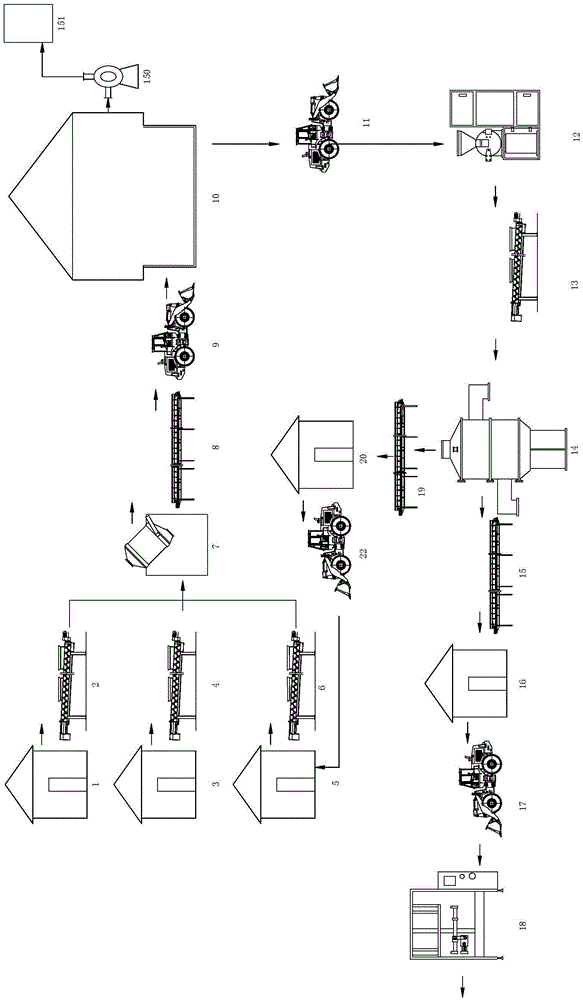

Sludge solar enhanced biological treatment process and device

A technology of biological enhancement and treatment process, which is applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of insufficient sludge reduction capacity, etc., to improve the heating rate, operation stability, and treatment time Short, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

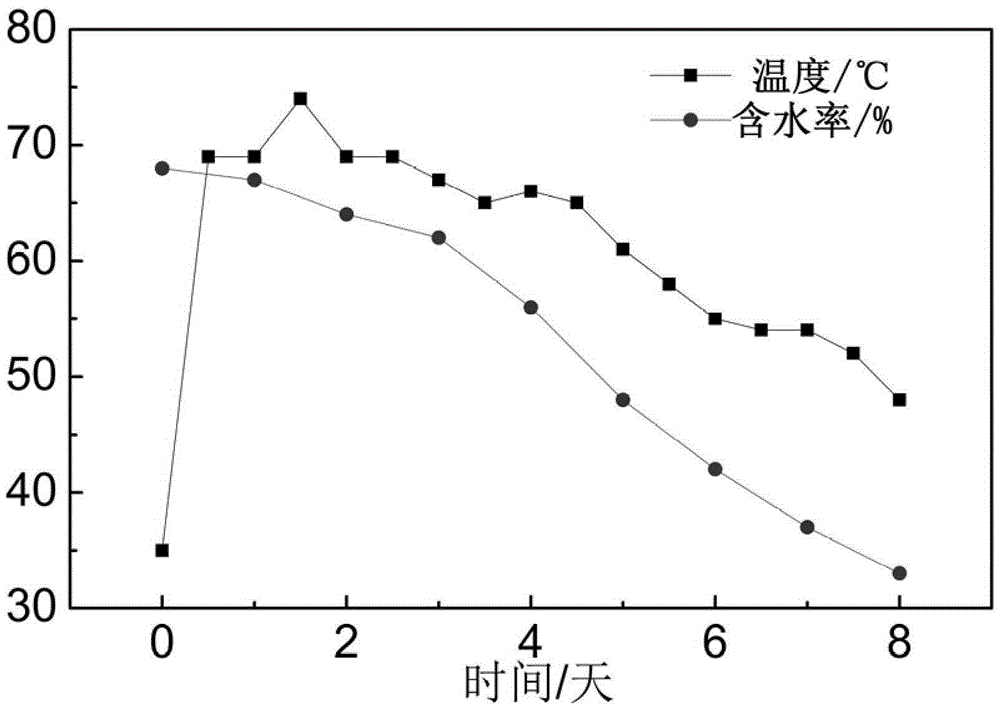

[0044] Take 30 tons of dewatered sludge with a water content less than 80% from the urban sewage treatment plant and transport it to the raw sludge storage bin by transport vehicle, and transport it to the mixing mixer through a screw conveyor (or loading vehicle), and conditioner (bran, bran, Sawdust), aerobic biological agent (the aerobic biological agent that can oxidize and decompose the sludge includes thermophilic fungi and thermophilic actinomycetes, etc.) are mixed and prepared, and the dosage rate of the conditioner is mixed After 10% of the total amount, the amount of aerobic biological agent added is 100 kg, and the moisture content of the sludge after deployment is 70%.

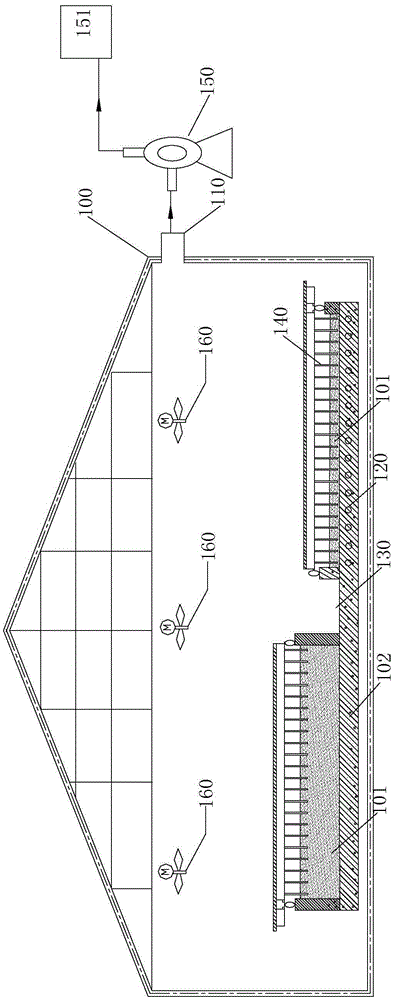

[0045] After the raw material sludge, conditioner and bacterial agent are evenly mixed, they are transported to the solar bioaugmentation treatment system for bioaugmentation-assisted solar drying treatment. In the high-temperature gel-breaking area, the size of the mixed sludge pile is 12m in len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com