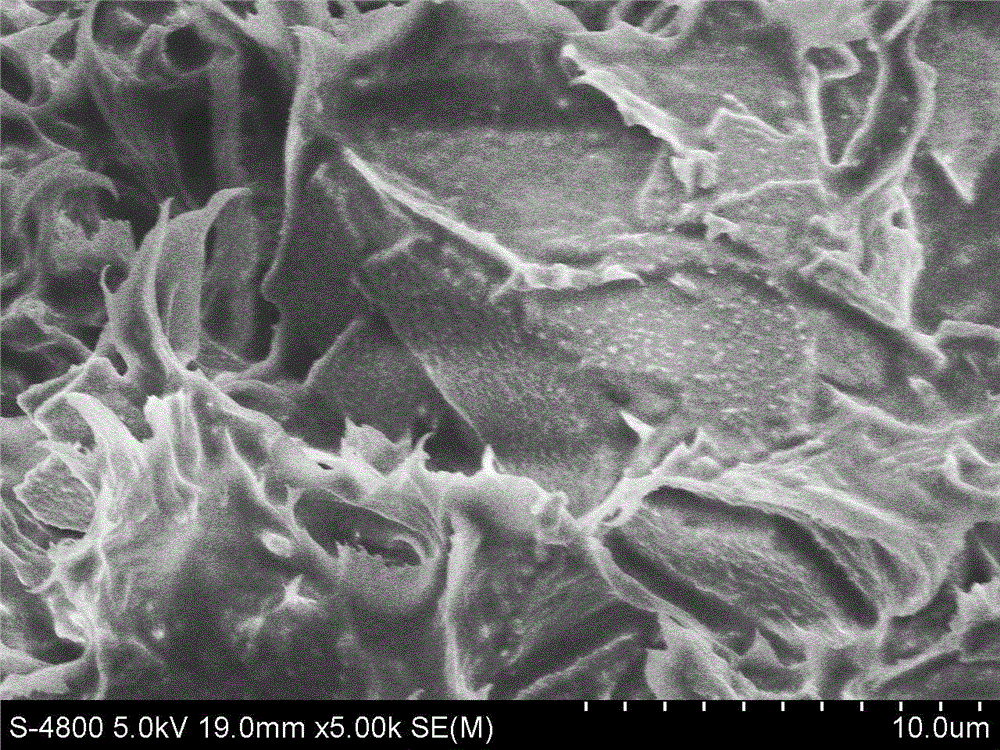

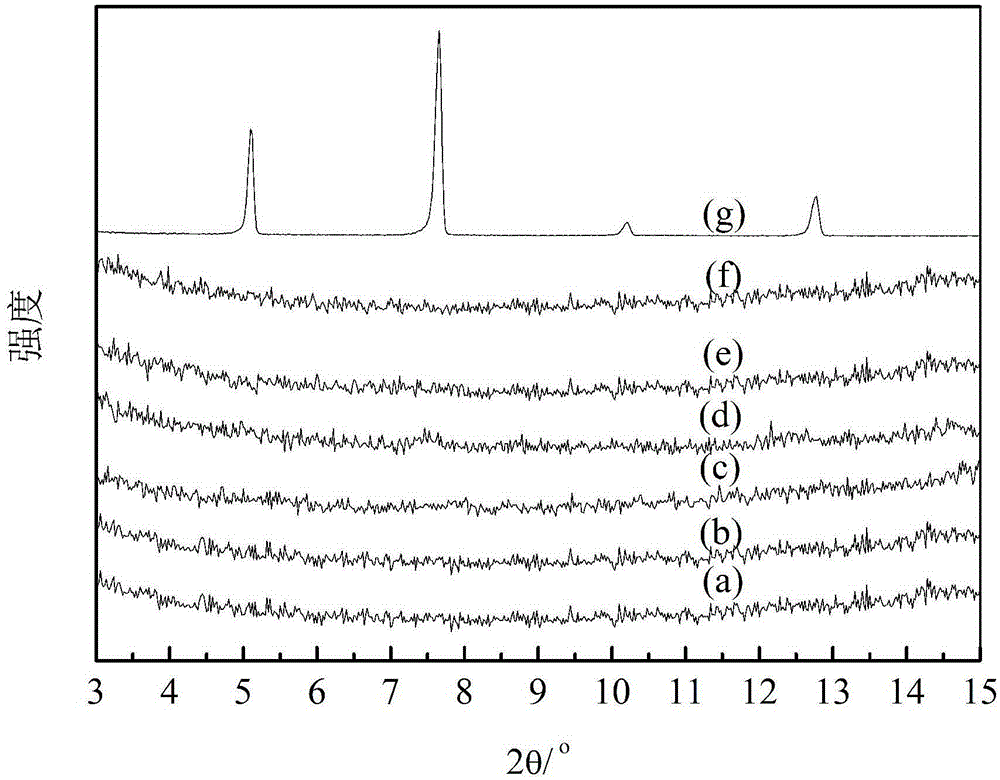

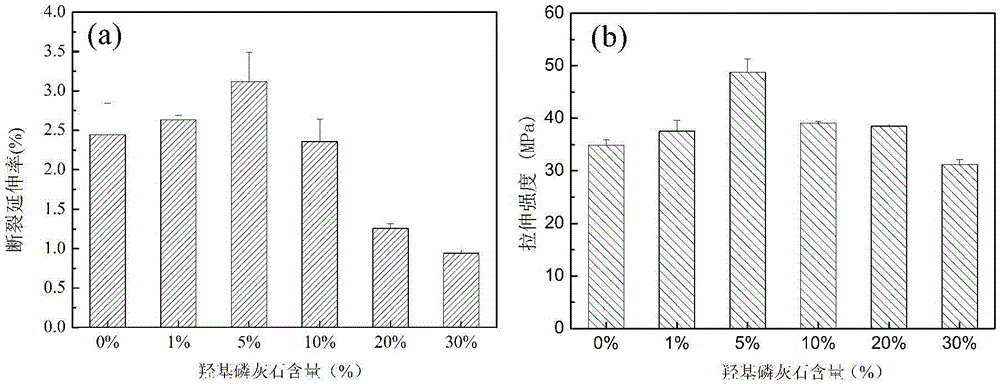

Sheet hydroxyapatite/polylactic acid nanometer composite prepared through in-situ intercalation method

A technology of hydroxyapatite and nano-hydroxyapatite, which is applied in the field of biomedical materials, can solve problems such as the contradiction between strength and toughness, complicated preparation steps, and difficult dispersion of nanoparticles, and achieve good biocompatibility and simple preparation process , the effect of excellent interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolve 1.88mmol of lauric acid and 50mmol of calcium nitrate tetrahydrate in 60ml of ethanol aqueous solution (the volume ratio of ethanol to water is 1:1), and stir evenly at 37°C.

[0020] (2) Weigh 30mmol of diammonium hydrogen phosphate and add it to 60ml of ethanol aqueous solution (the volume ratio of ethanol to water is 1:1), pour the prepared diammonium hydrogen phosphate solution into a constant pressure dropping funnel, and place it at 37°C under magnetic force Slowly add dropwise at a speed of 2ml / min into the mixed solution of calcium nitrate tetrahydrate and lauric acid under stirring.

[0021] (3) After the above mixed solution was stirred for 0.5 hours, 40ml of 2M sodium hydroxide ethanol aqueous solution (the volume ratio of ethanol to water was 1:1) was added dropwise, reacted at 37°C for 2 hours, heated in water at 100°C for 8h, and mixed with ethanol and After washing with hot water and suction filtration for 3 times, dry it.

[0022] (4) Take ...

Embodiment 2

[0025] (1) Dissolve 3.76mmol of lauric acid and 50mmol of calcium nitrate tetrahydrate in 60ml of ethanol aqueous solution (the volume ratio of ethanol to water is 1:1), and stir evenly at 37°C.

[0026] (2) Weigh 30mmol of diammonium hydrogen phosphate and add it to 60ml of ethanol aqueous solution (the volume ratio of ethanol to water is 1:1), pour the prepared diammonium hydrogen phosphate solution into a constant pressure dropping funnel, and place it at 37°C under magnetic force Slowly add dropwise at a speed of 3ml / min into the mixed solution of calcium nitrate tetrahydrate and lauric acid under stirring.

[0027] (3) After the above mixed solution was stirred for 1 hour, 40ml of 2M sodium hydroxide ethanol aqueous solution (the volume ratio of ethanol to water was 1:1) was added dropwise, reacted at 37°C for 4 hours, heated in water at 100°C for 12h, and mixed with ethanol and After washing with hot water and suction filtration for 4 times, dry.

[0028] (4) Take 100 p...

Embodiment 3

[0031] (1) Dissolve 18.8mmol of lauric acid and 50mmol of calcium nitrate tetrahydrate in 60ml of ethanol aqueous solution (the volume ratio of ethanol to water is 1:1), and stir evenly at 37°C.

[0032] (2) Weigh 30mmol of diammonium hydrogen phosphate and add it to 60ml of ethanol aqueous solution (the volume ratio of ethanol to water is 1:1), pour the prepared diammonium hydrogen phosphate solution into a constant pressure dropping funnel, and place it at 37°C under magnetic force Slowly add dropwise at a speed of 4ml / min into the mixed solution of calcium nitrate tetrahydrate and lauric acid under stirring.

[0033] (3) After the above mixed solution was stirred for 1 hour, 40ml of 2M sodium hydroxide ethanol aqueous solution (the volume ratio of ethanol to water was 1:1) was added dropwise, reacted at 37°C for 6 hours, heated in water at 100°C for 24h, and mixed with ethanol and After washing with hot water and suction filtration for 5 times, dry.

[0034] (4) Take 100 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com