Method for regulation and control of crystal form of isotatic polypropylene (iPP)-ethylene propylene diene monomer (EPDM) rubber-plastic blended material by double constant temperature heating stages

A technology of EPDM10, rubber and plastic, which is applied in the field of regulating the crystal form of iPP-EPDM rubber and plastic blend materials with double constant temperature heating stages, achieving the effects of low equipment cost, convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

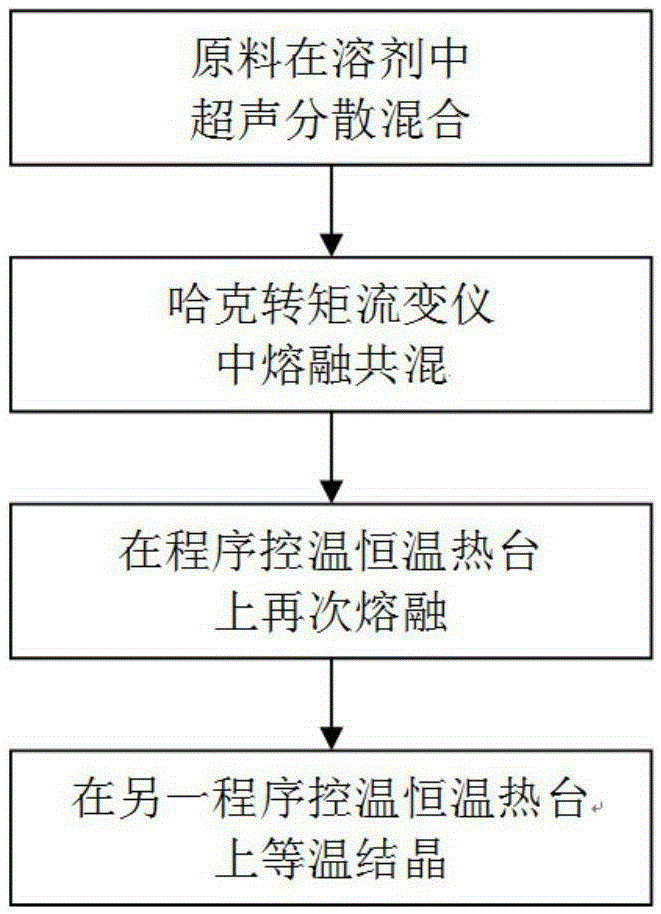

[0027] The present invention regulates the crystal form in the iPP-EPDM rubber-plastic blended material according to the following steps:

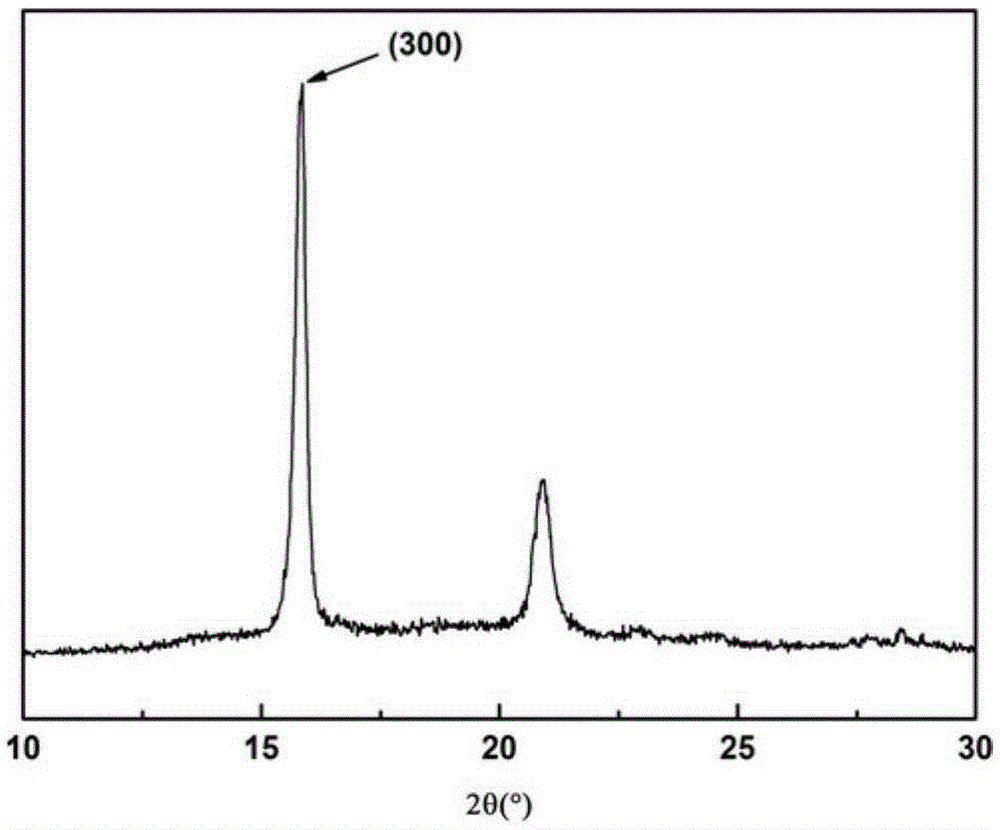

[0028] First, 80 parts by mass of isotactic polypropylene (Sinopec Yangzi Petrochemical Co., Ltd., brand F401), 20 parts by mass of EPDM, and 0.1 parts by mass of nucleating agent TMB-5 (Shanxi Chemical Research Institute) were mixed in absolute ethanol Ultrasonic mixing is uniform at room temperature, and then the absolute ethanol is evaporated to dryness, and the mixed raw materials are put into a Haake torque rheometer for melt blending (temperature 170°C, mixing time 10min, rotor speed 60r / min), and then The sample was taken out and placed on the first constant-temperature heating stage (melting heating stage, constant temperature 180°C) for re-melting. After the sample was completely melted, it was quickly transferred to the second constant-temperature heating stage (crystallization heating stage, constant temperature 100°C). Under th...

Embodiment 2

[0031] The present invention regulates the crystal form in the iPP-EPDM rubber-plastic blended material according to the following steps:

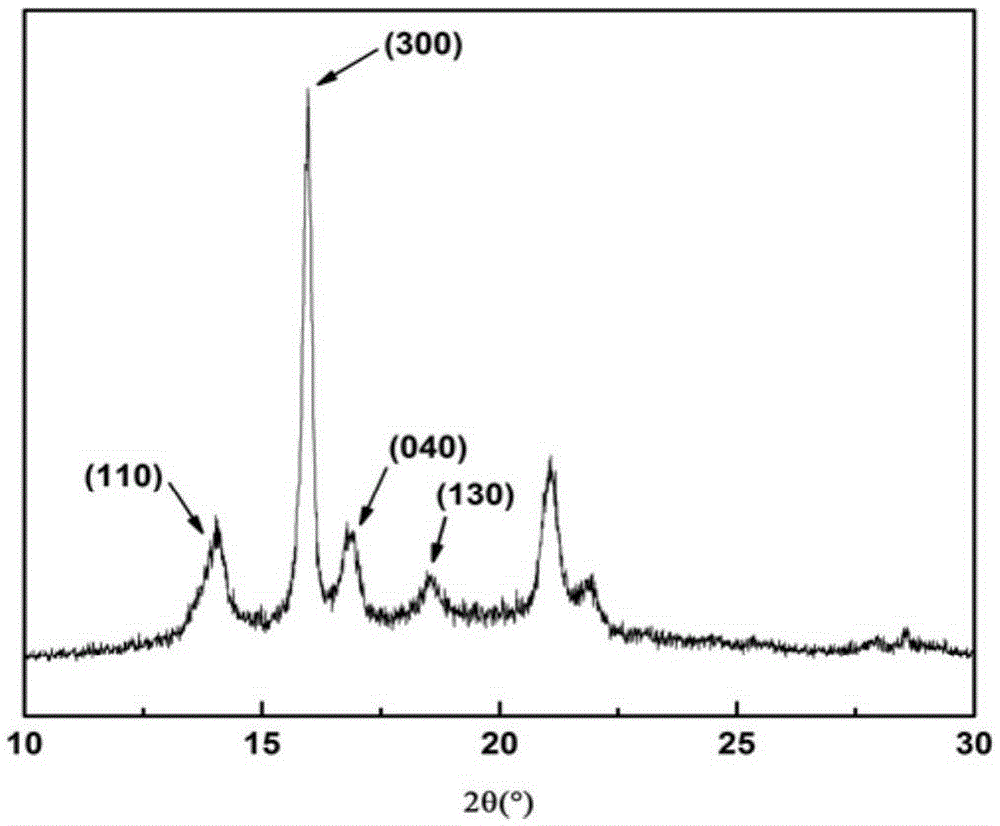

[0032] First, 80 parts by mass of isotactic polypropylene (China Lanzhou Petrochemical Co., Ltd., brand T30S), 20 parts by mass of EPDM, and 0.1 part by mass of nucleating agent NT-C (Nanjing Chengkuan Trading Co., Ltd.) were ultrasonicated in xylene at room temperature. Mix well, then evaporate the xylene to dryness, add the Haake torque rheometer for melt mixing (temperature 170°C, mixing time 10min, rotor speed 60r / min), then take the sample out and put it in the first constant temperature Melt again on the hot stage (melting hot stage, the temperature of the hot stage is controlled at 180°C), and after the sample is completely melted, it is quickly transferred to the second constant temperature hot stage (the crystallization hot stage, the temperature of the hot stage is controlled at 130°C). The isothermal crystallization was carried ...

Embodiment 3

[0035] The present invention regulates the crystal form in the iPP-EPDM rubber-plastic blended material according to the following steps:

[0036]First, 75 parts by mass of isotactic polypropylene (China Lanzhou Petrochemical Co., Ltd., brand T30S), 25 parts by mass of EPDM, 0.2 parts by mass of nucleating agent TMB-5 (Shanxi Chemical Research Institute), 2 parts by mass of sulfur and 2 parts by mass of zinc oxide. Parts by mass, ultrasonically mixed in acetone at room temperature, then evaporated acetone to dryness, added to a Haake torque rheometer for melt mixing (temperature 180 ° C, mixing time 12min, rotor speed 60r / min), and then The sample was taken out and put on the first constant temperature hot stage (melting hot stage, the temperature of the hot stage was controlled at 190°C) for re-melting. Temperature 130°C), and isothermal crystallization was carried out at this temperature for 20 minutes, and then the sample was rapidly cooled to room temperature to obtain iPP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com