Manufacturing method of fire blanket

A manufacturing method and technology of fire blankets, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor flame retardant effect, low production efficiency, high production cost, etc., and achieve excellent product strength, soft texture, heat insulation and flame retardant good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

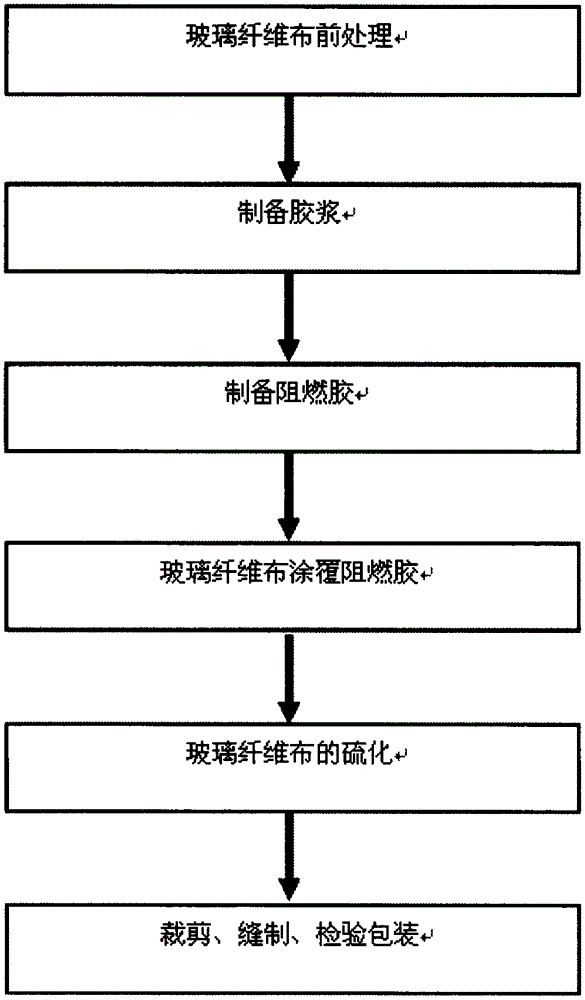

Image

Examples

Embodiment 1

[0019] Embodiment 1: This embodiment is a method for manufacturing a fire extinguishing blanket. The specifications of the fire extinguishing blanket are: length 1800mm, width 1500mm.

[0020] The manufacturing steps are as follows:

[0021] A) Pre-treatment of the glass fiber cloth, wash the glass fiber cloth twice with detergent, then wash off the residual detergent on the surface of the glass fiber cloth with water, and then place the glass fiber cloth in an oven to dry.

[0022] B) Preparation of mucilage: 2 parts by mass of raw rubber, 1.5 parts by mass of silicon dioxide, and 1 part by mass of hydroxy silicone oil, uniformly mixed to form a mucilage.

[0023] C) Preparation of flame retardant glue: 60 parts of mucilage, 5 parts by mass of aluminum hydroxide, 2 parts of sodium citrate, 6 parts by mass of magnesium hydroxide, 7 parts by mass of antimony trioxide, 10 parts by mass of decabromodiphenyl ether, 7 parts by mass of 1 part polytetrafluoroethylene, 5 parts iron o...

Embodiment 2

[0027] Embodiment 2: This embodiment is a method for manufacturing a fire extinguishing blanket. The specifications of the fire extinguishing blanket are: length 1000 mm, width 1000 mm.

[0028] The manufacturing steps are as follows:

[0029] A) Pretreatment of glass fiber cloth, wash the glass fiber cloth once with detergent, then wash off the residual detergent on the surface of the glass fiber cloth with water, and then place the glass fiber cloth in an oven to dry.

[0030] B) Preparation of mucilage: 1 part by mass of raw rubber, 0.5 part by mass of silicon dioxide, and 0.5 part by mass of hydroxy silicone oil were uniformly mixed to form a mucilage.

[0031] C) Preparation of flame retardant glue: 70 parts of mucilage, 5 parts by mass of aluminum hydroxide, 2 parts of sodium citrate, 6 parts by mass of magnesium hydroxide, 7 parts by mass of antimony trioxide, 15 parts by mass of decabromodiphenyl ether, 8 parts by mass 1 part polytetrafluoroethylene, 4 parts iron oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com