Combustion system and combustion method for retarding slagging and contamination of high-alkali coal boiler for combustion

A combustion system and high-alkali coal technology, applied in the field of coal-fired boilers, can solve the problems of increased heat transfer resistance, fluctuating combustion in the furnace chamber, even fire extinguishing, increased coal input, etc. The effect of reducing smoke loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

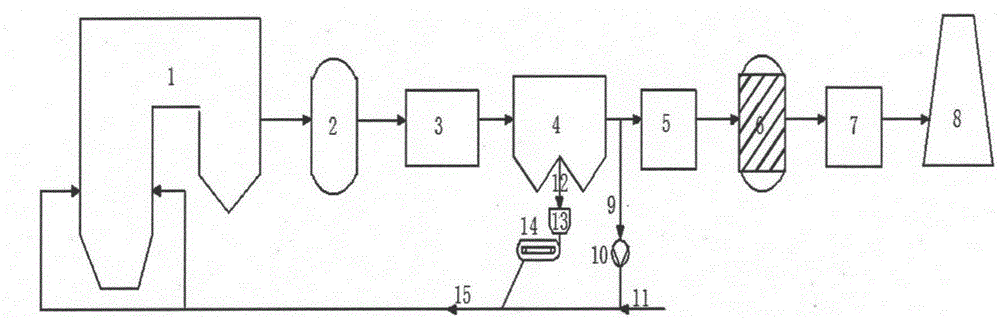

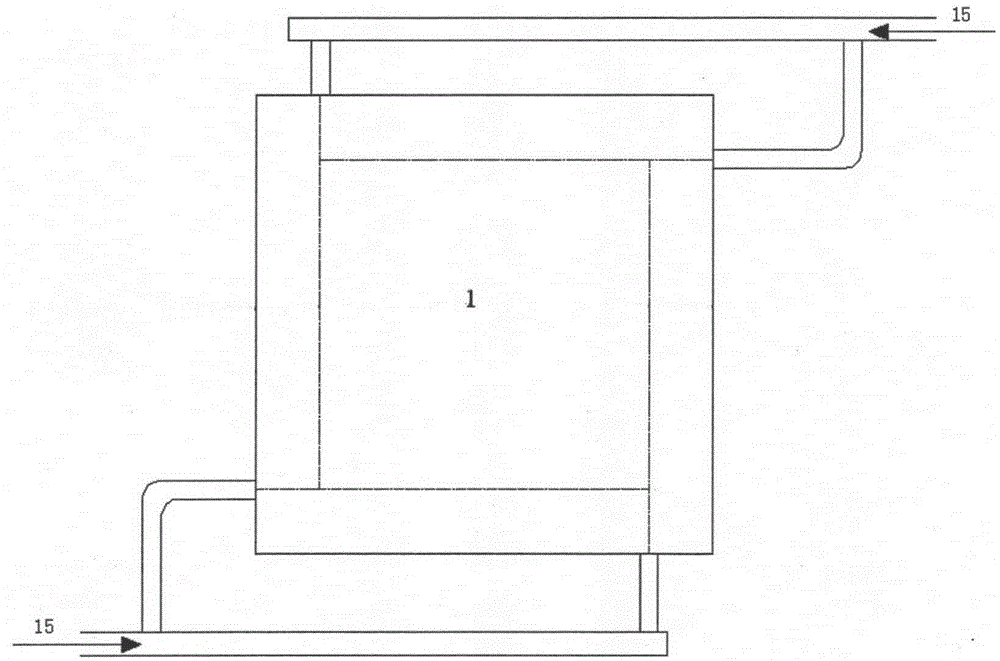

[0031] figure 1 The schematic diagram of the combustion system for slowing down the slagging and fouling of the high-alkali coal-fired boiler provided in this embodiment, the described combustion system for slowing down the slagging and fouling of the high-alkali coal-fired boiler consists of boiler 1, denitrification equipment 2, air Preheater 3, dry electrostatic precipitator 4, first flue gas-flue gas reheater GGH5, wet desulfurization equipment 6, second flue gas-flue gas reheater GGH7, chimney 8, recirculation flue gas pipe Road 9, circulating fan 10, primary air pipeline 11, circulating ash pipeline 12, ash bin 13, ash conveyor 14, flue gas with circulating ash, air mixture pipeline 15 and the like.

[0032] Boiler 1, denitrification equipment 2, air preheater 3, dry electrostatic precipitator 4, first flue gas-flue gas reh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com