Nanocomposite catalyst and its preparation method and application

A nanocomposite and nanocluster technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of low precious metal loading efficiency and metal nanocluster adsorption capacity. Not strong, low metal load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1, the preparation metal content is the Pt-Cu alloy nano-cluster composite catalyst Pt-Cu / MDC1-1 of 16wt% (method one)

[0095] Dissolve 0.1g of melamine in 100mL of water to make a melamine solution. Conductive carbon black (commercially available XC-72R, 0.4g, specific surface area 254m 2 / g) was added to the above-mentioned melamine solution, ultrasonically treated for 20 minutes, and heated in an oil bath at 150° C. to evaporate the solvent water to obtain a melamine-carbon material ( XC-72R) mixture. Under the air atmosphere, the mixture was heated to 613K in a muffle furnace, kept for 1 h and then cooled to room temperature to obtain a carbon material MDC1-1 modified by melamine polycondensate. Elemental analysis showed that the nitrogen content in MDC1-1 was 4.4%. BET specific surface area test shows that the specific surface area of MDC1-1 is 100m 2 / g.

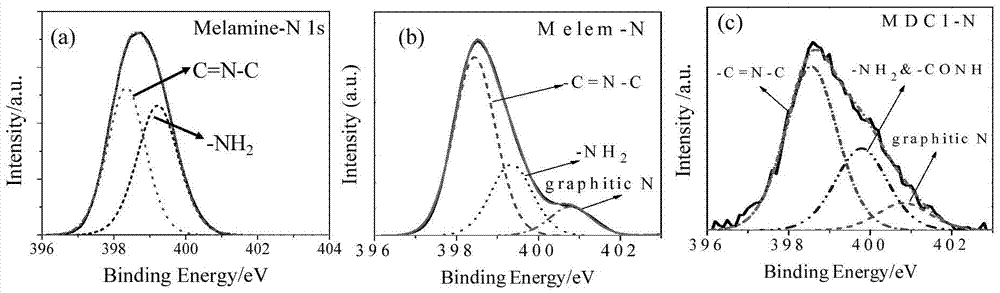

[0096] attached figure 1 The N1s XPS spectra of the raw material Melamine (a), the mela...

Embodiment 2

[0106] Example 2, the preparation of a Pt-Cu alloy nanocluster composite catalyst Pt-Cu / MDC1-2 with a metal content of 41wt%

[0107] (method one)

[0108] The carbon material MDC1-1 modified by melamine condensation polymer was prepared according to the method described in Example 1.

[0109] Dissolve 1 g of chloroplatinic acid hexahydrate in 50 mL of ethylene glycol for later use. Under stirring condition at 313K, 7.6mL chloroplatinic acid hexahydrate (0.31mmol) ethylene glycol solution was added in the ethylene glycol solution (227mL) that was dissolved with 150mg copper acetate monohydrate, the ethylene glycol solution (0.25mol) of NaOH / L) adjust the pH of the above solution to 10, and stir for 30 minutes. The above mixture was added dropwise to 324 mL of ethylene glycol solution in which MDC1-1 (350 mg) was dispersed, heated to reflux at 471K for 4 hours under a nitrogen atmosphere, cooled to room temperature, filtered, washed, and vacuum-dried at 343K for 5 hours. Ta...

Embodiment 3

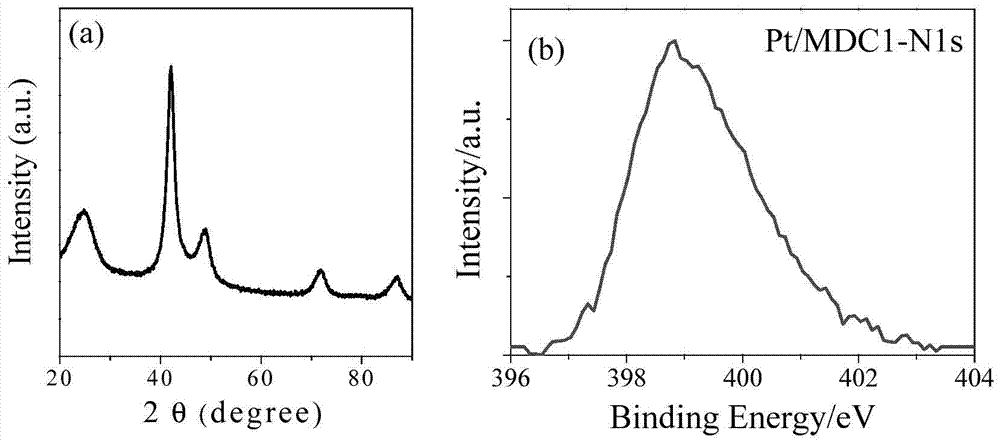

[0110] Example 3, the preparation of a Pt-Cu alloy nanocluster composite catalyst Pt-Cu / MDC1-3 with a metal content of 27.8wt%

[0111] The Pt-Cu / MDC1-2 catalyst (50mg) prepared in Example 2 was ultrasonically dispersed in 1M nitric acid (20mL), stirred at 298K for 20 hours, centrifuged and washed with water to remove residual acid, the resulting solid product Vacuum drying at 298K for 3 hours to prepare Pt-Cu alloy nano-cluster composite catalyst Pt-Cu / MDC1-3. ICP-AES analysis showed that the Pt / Cu atomic ratio in Pt-Cu / MDC1-3 was 72:28, and the Pt metal loading was 24.7wt%.

[0112] The TEM photo of the PtCu / MDC1-3 catalyst is attached Figure 5 shown. In Pt-Cu / MDC1-3, the average particle size of metal nanoparticles is 2.1 nm, and the particle size distribution is 1.5-3.5 nm.

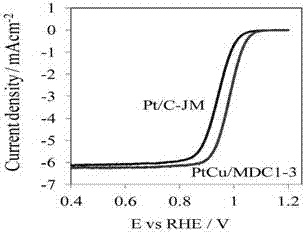

[0113] Test the Pt-Cu / MDC1-3 catalyst prepared by embodiment 3 and commercially available Pt / C-JM catalyst (platinum content: 52wt%) to the electrocatalytic activity of oxygen reduction reaction b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com