FeS nanosheet preparing method

A technology of nanosheets and precursors is applied in the field of preparation of FeS nanosheets to achieve the effects of uniform morphology, safe preparation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

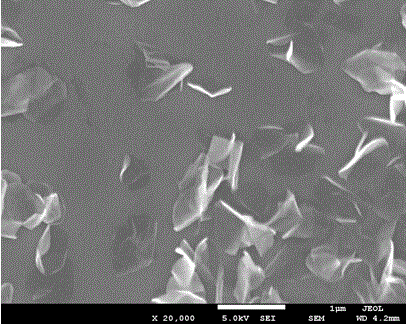

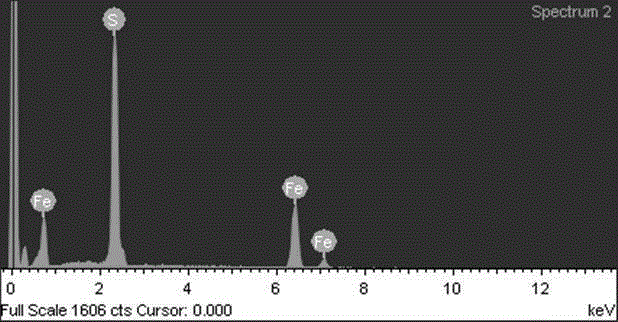

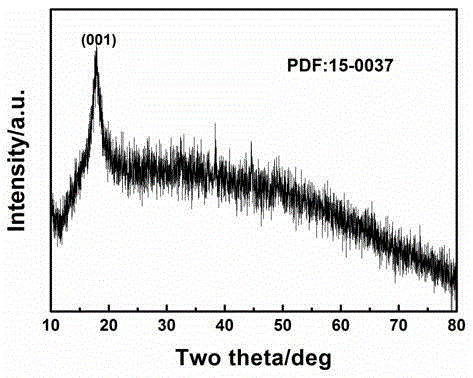

[0023] A preparation method of FeS nanosheets, comprising the following steps:

[0024] Step 1, dissolving the iron-containing precursor, the sulfur-containing precursor and a surfactant in water to prepare a solution, the surfactant being cetyltrimethylammonium bromide;

[0025] Step 2. Transfer the solution prepared in Step 1 to a reaction kettle and heat it. After the reaction is complete, centrifuge and wash the sample with water and alcohol to prepare FeS nanosheets.

[0026] Wherein, in step 1, the iron-containing precursor is ferrous chloride, ferrous acetate or ferrous sulfate; the sulfur-containing precursor is thiourea, thioacetamide, sodium sulfide, cysteine or reduced glutathione . The molar ratio of the iron-containing precursor to the sulfur-containing precursor is 1:1 to 1:12; the molar ratio of the iron-containing precursor to the surfactant is 1:0.1 to 1:2.

[0027] In step 2, the reaction temperature is 120°C to 240°C; the reaction time is 1h to 18h.

[...

Embodiment 1

[0031] Step 1, 1mmol ferrous acetate, 1mmol thioacetamide, 0.1mmol cetyltrimethylammonium bromide (CTAB) are dissolved in 80ml water to obtain a solution;

[0032] Step 2. Transfer the solution prepared in Step 1 to a reactor for heating, control the reaction temperature to 120° C., react for 1 hour, centrifuge, wash the sample with water and alcohol, and prepare FeS nanosheets.

Embodiment 2

[0034] Step 1, 1mmol ferrous chloride, 10mmol cysteine, 0.5mmol cetyltrimethylammonium bromide (CTAB) are dissolved in 80ml water to obtain a solution;

[0035] Step 2. Transfer the solution prepared in Step 1 to a reactor for heating, control the reaction temperature to 160° C., react for 6 hours, centrifuge, wash the sample with water and alcohol, and prepare FeS nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com