Comprehensive treatment method for glyphosate wastewater

A technology for comprehensive treatment of glyphosate wastewater, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems that are difficult to achieve, increase treatment costs, increase the cost of chemical use, etc. problem, to achieve good removal effect, to achieve the effect of removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 1000g of phosphorus-containing wastewater, add 2.5g of 30% hydrochloric acid under stirring at 20°C, and adjust the pH to 4.2. Gradually add the above-mentioned aluminum-containing wastewater at this temperature, and keep it warm for 35 minutes, maintain the end point pH=6.15, and consume 3.4g of aluminum-containing wastewater. Add 3.5 g of 0.3% cationic PAM (polyacrylamide) flocculant aqueous solution under stirring state, continue to stir for 5 minutes and then let it stand still, a certain amount of precipitation occurs. After being poured and filtered, the clear liquid was taken for analysis, wherein the aluminum element content was 1.8ppm, the total phosphorus was 4.5mg / L, the COD was 312mg / L, and the chloride ion content was 0.08%. According to the calculation, the removal rate of aluminum element reaches 98.8%, the removal rate of total phosphorus reaches 95.5%, and the removal rate of COD reaches 63.3%.

Embodiment 2~8

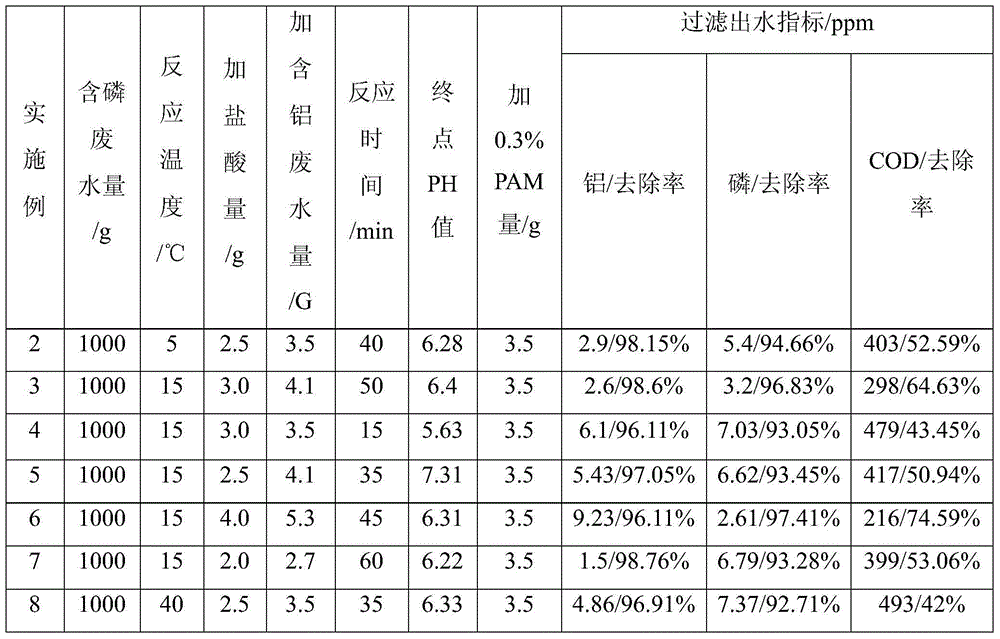

[0033] The test process is basically the same as in Example 1, and the optimization of the technical control point and the analysis of its results are specifically shown in Table 1:

[0034] Table 1: Statistics of Experimental Data of Embodiments 2 to 8

[0035]

Embodiment 9

[0037] Take 1000 g of phosphorus-containing wastewater, and add 3.5 g of the above-mentioned aluminum-containing wastewater under stirring at 20° C., and the pH at this time is 9.6. Gradually add 30% hydrochloric acid at this temperature and keep it warm for 35 minutes to maintain the end point pH=6.28 and hydrochloric acid 2.4. Add 3.5 g of 0.3% PAM aqueous solution under stirring state, continue to stir for 5 min and then let it stand still, a certain amount of precipitation occurs. After being poured and filtered, the clear liquid was taken for analysis, wherein the aluminum element content was 17.55ppm, the total phosphorus was 14.1mg / L, the COD was 503mg / L, and the chloride ion content was 0.08%. According to the calculation, the removal rate of aluminum element reaches 88.83%, the removal rate of total phosphorus reaches 85.9%, and the removal rate of COD reaches 40.82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com