Processing method for ketoxime type silane byproduct ketoxime salt

A treatment method, ketoxime-type technology, applied in the direction of nitrogen and non-metallic compounds, hydrolysis to prepare carbonyl compounds, hydroxylamine, etc., can solve the problems of high production cost, unfavorable water balance of production system, large sewage discharge, etc., and achieve reduction in treatment cost, benefit process water circulation, and reduce the effect of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

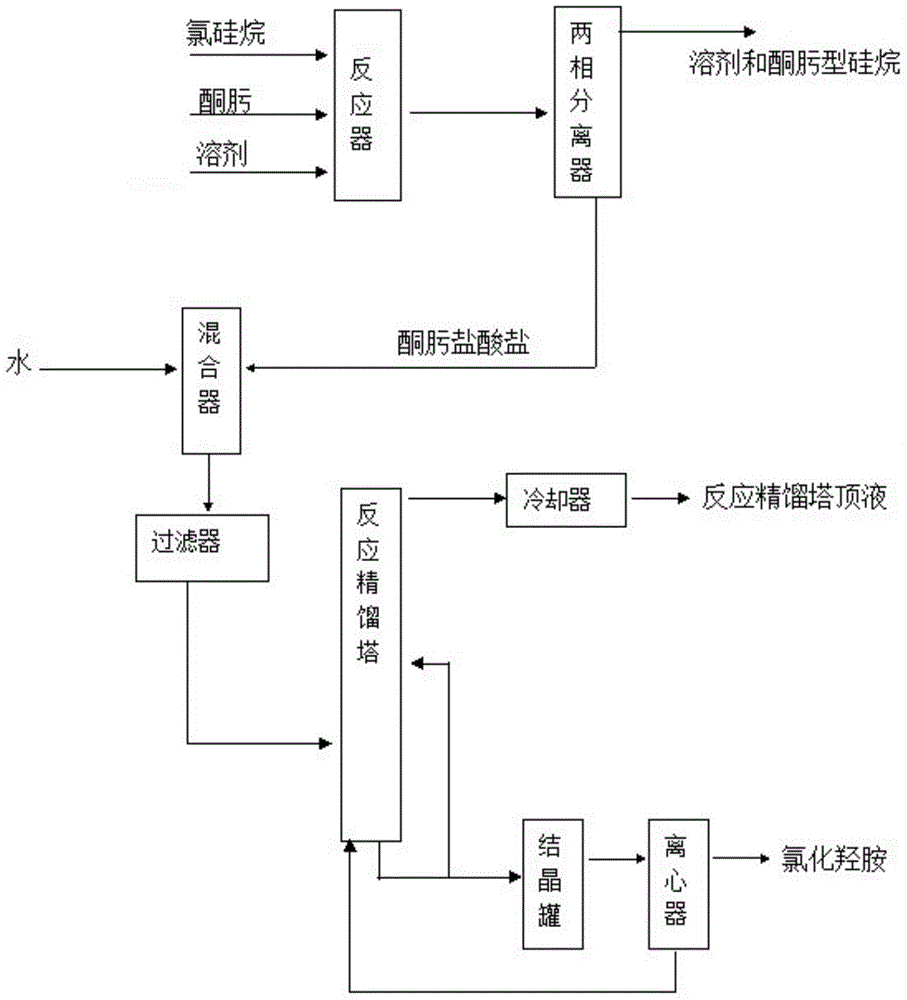

Image

Examples

Embodiment 1

[0019] In the production process of ketoxime type silane, after the two-phase separator settles and separates layers, the ketoxime hydrochloride precipitate of the lower floor is separated and taken out, and 123.5g butanone oxime hydrochloride (1mol) is added to the mixer, and then Add 360g (20mol) of desalinated water at a high speed to mix thoroughly, feed the material from the feed port in the rectification tower after filtration, and turn on the vacuum pump connected to the vacuum pump port to control the vacuum degree in the tower at 0.05MPa. The internal temperature is controlled at 70-100°C, the reflux ratio in the tower is 4, the kettle liquid is partially circulated, and the produced butanone is discharged from the top of the tower through the cooler in time, part of the kettle liquid is cooled and crystallized by the crystallization tank, and filtered and dried to obtain chlorinated Hydroxylamine 65g, yield 94%, titration content 99.1%.

Embodiment 2

[0021] In the production process of ketoxime type silane, after the two-phase separator settles and separates layers, the ketoxime hydrochloride precipitate in the lower layer is separated and taken out, and 109.5g of acetone oxime hydrochloride (1mol) is added to the mixer, and then at a certain speed Add 360g (20mol) of desalinated water for thorough mixing, feed the material from the feed port in the rectification tower after filtration, turn on the vacuum pump connected to the vacuum pump port, and control the vacuum degree in the tower at 0.05MPa, and the vacuum in the rectification tower still The temperature is controlled at 70-100°C, the reflux ratio in the tower is 4, the kettle liquid is partially circulated, and the butanone produced is discharged from the top of the tower through the cooler in time, part of the kettle liquid is cooled and crystallized by the crystallization tank, and filtered and dried to obtain hydroxylamine chloride 67g, yield 96%, titration conte...

Embodiment 3

[0023] In the production process of ketoxime type silane, after the two-phase separator settles and separates layers, the ketoxime hydrochloride precipitate in the lower layer is separated and taken out, and 149.6g cyclohexanone oxime hydrochloride (1mol) is added to the mixer, and then Add 360g (20mol) of desalted water at a certain speed for thorough mixing, feed the material from the feed port in the rectification tower after filtration, and turn on the vacuum pump connected to the vacuum pump port to control the vacuum degree in the tower at 0.05MPa. The temperature in the kettle is controlled at 70-100°C, the reflux ratio in the tower is 5, the kettle liquid is partially circulated, and the produced butanone is discharged from the top of the tower through the cooler in time, part of the kettle liquid is cooled and crystallized by the crystallization tank, and filtered and dried to obtain chlorine Hydroxylamine 134g, yield 96%, titration content 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com