Method for preparing polyaniline-ferroferric oxide (PANI-Fe3O4) nanocomposite by solvothermal method

A technology of nano-composite materials, ferroferric oxide, applied in the field of nano-composite materials, can solve problems such as environmental pollution, complicated preparation process, difficulty in obtaining high purity and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

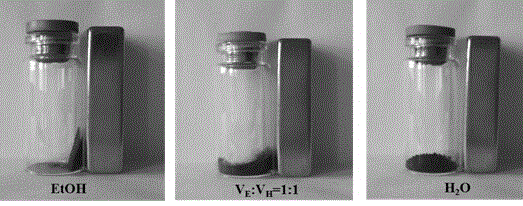

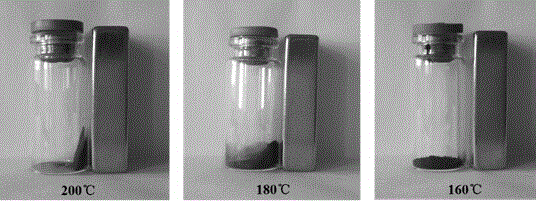

Method used

Image

Examples

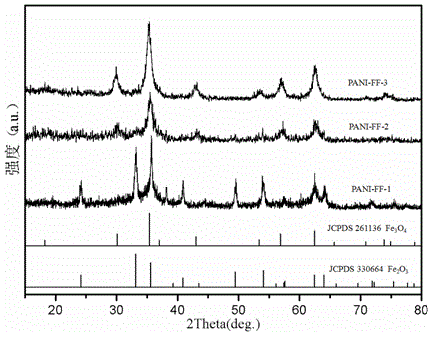

Embodiment 1

[0037] 2.424gFe(NO 3 ) 3 9H 2 O and 0.10mL aniline monomer were added to 48mL EtOH, stirred and dissolved, then transferred to a polytetrafluoroethylene reactor, and reacted for 10h at 200°C. After the reaction, centrifuge, wash with absolute ethanol and twice with water, place in a drying oven, and dry at 90-100°C for 9-11 hours to obtain the composite material PANI-FF-1. A certain amount of the material was calcined at 700°C for 2 hours, and the actual composite amount of PANI in the composite material was calculated to be 21% according to the mass change before and after calcination. The composite material had a magnetization of 7.53 emu / g.

Embodiment 2

[0039] The addition of aniline monomer is 0.50mL, and other conditions are with embodiment 1, and the composite material PANI-FF-2 that obtains, with embodiment 1, the actual composite amount of PANI recorded in this composite material is 37%; Its magnetization is 30.73emu / g.

Embodiment 3

[0041] The add-on of aniline monomer is 1.00mL, and other conditions are with embodiment 1, and the composite material PANI-FF-3 that obtains, with embodiment 1, the actual composite amount of PANI recorded in this composite material is 48%; Its magnetization is 42.91 emu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com