Solvothermal preparation method of polyaniline-ferric oxide nanocomposite material

A technology of nanocomposite materials, ferric oxide, applied in the field of nanocomposite materials, can solve the problems of high cost, complicated preparation process, difficulty in obtaining high purity and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

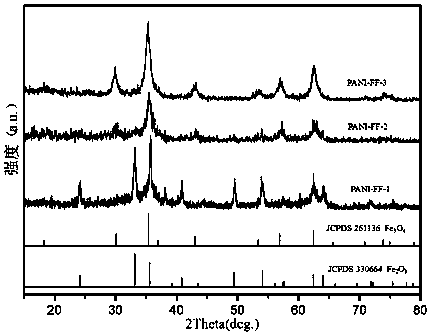

Embodiment 1

[0038] 2.424g Fe(NO 3 ) 3 9H 2 O and 0.10 mL of aniline monomer were added to 48 mL of EtOH, stirred and dissolved, then transferred to a polytetrafluoroethylene reactor, and reacted at 200 °C for 10 h. After the reaction, centrifuge, wash with absolute ethanol, and twice with water, place in a drying oven, and dry at 90-100 °C for 9-11 h to obtain the composite material PANI-FF-1. A certain amount of the material was calcined at 700 °C for 2 h, and the actual composite amount of PANI in the composite material was calculated to be 21% according to the mass change before and after calcination. The composite has a magnetization of 7.53 emu / g.

Embodiment 2

[0040] The addition of aniline monomer is 0.50 mL, and other conditions are with embodiment 1, and the composite material PANI-FF-2 that obtains, with embodiment 1, the actual composite amount of PANI recorded in this composite material is 37%; Its magnetization is 30.73 emu / g.

Embodiment 3

[0042] The add-on of aniline monomer is 1.00 mL, and other conditions are with embodiment 1, and the composite material PANI-FF-3 that obtains, with embodiment 1, the actual composite amount of PANI recorded in this composite material is 48%; Its magnetization is 42.91 emu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com