Electrorheological fluid preparation method

An electrorheological fluid and product technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of insufficient service life and stability, high cost, complicated preparation process, etc., achieve good mechanical response, not easy to wear, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Put 200 grams of petroleum catalytic cracking clarified oil slurry in a 500ml coking tank, and use N 2 After replacing the air in the kettle, raise the temperature to 420°C, maintain and control the pressure at 1Mpa, after the light components <400°C are distilled, raise the temperature to 500°C and keep for 1H, then lower the temperature. After taking out the coke, grind and sieve, take the granules in the sieving range of 0.1-75m, and mix them with methyl silicone oil with a viscosity of 50mPa. The electrorheological fluid of petroleum coke particles is made. The C / H atomic ratio of the coke particles is 2.2.

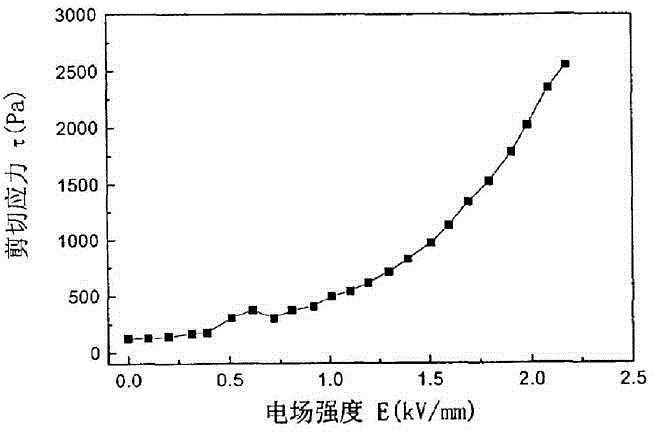

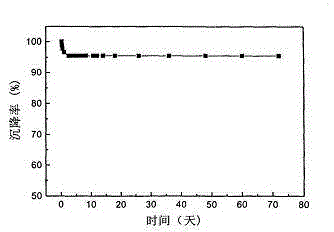

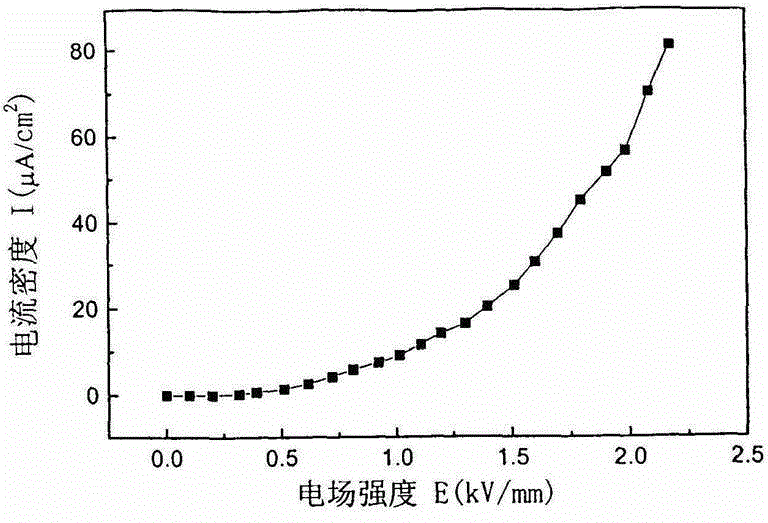

[0016] Pour this electrorheological fluid into the concentric cylinder type electrorheological tester, at a shear rate of 98s -1 Test the mechanical response and current density under the conditions of DC and DC electric field, the test results are shown in figure 1 with figure 2 . It can be seen from the figure that the shear stress of this electrorheolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com