Fermentation method for efficiently producing keratinase through recombinant escherichia coli

A technology of keratinase and fermentation method, which is applied in the field of fermentation engineering, can solve the problems of low keratinase production, unstable activity, and reduce the development and application of keratinase, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Construction of recombinant Escherichia coli capable of efficiently secreting keratinase

[0037](1) A gene sequence template SEQ ID NO. 1 of a highly active keratinase mutant obtained according to multiple molecular transformations in this experiment, or a template obtained by chemical synthesis, and subjected to PCR amplification. The reaction conditions are: pre-denaturation at 95°C for 5 minutes, followed by a cycle: denaturation at 98°C for 10 seconds, annealing at 55°C for 10 seconds, extension at 72°C for 7 minutes and 50 seconds, and 30 cycles; extension at 72°C for 1 minute and 50 seconds, and then cooling down to 12°C to obtain the final reaction solution. The DNA amplification enzyme used was PrimerSTAR from TaKaRa Company, and the formula was used according to the product manual.

[0038] (2) The amplified PCR product and the pET22b(+) plasmid were treated with NcoI and XhoI endonucleases to obtain DNA sequences at cohesive ends, and then ligated o...

Embodiment 2

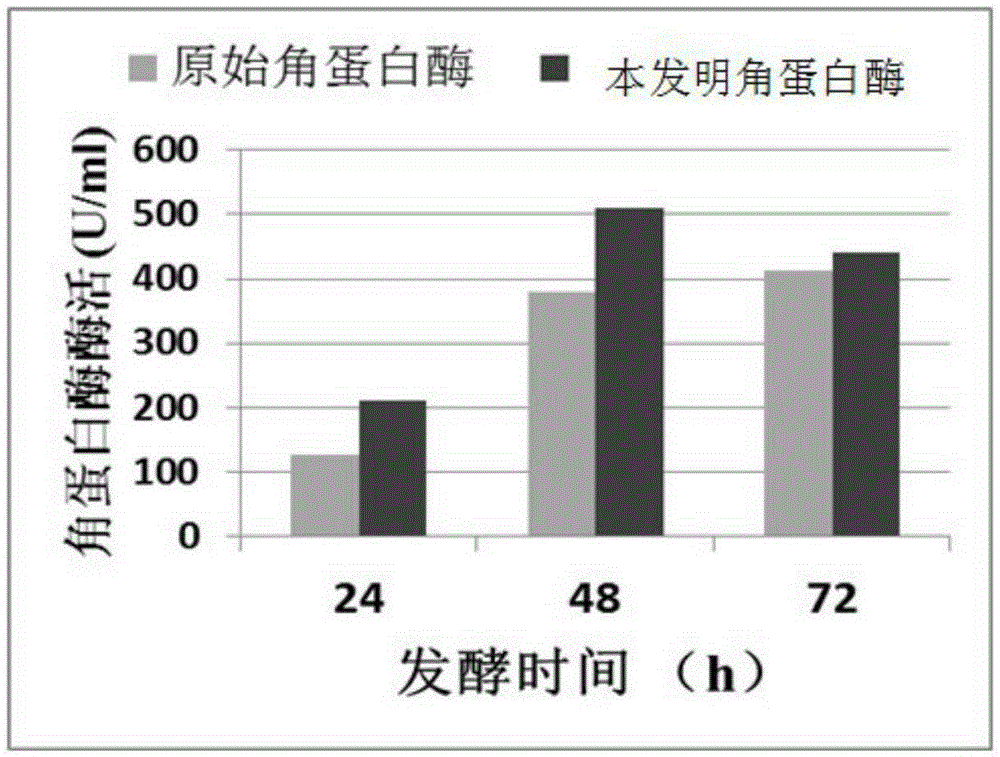

[0043] Fermentation optimization of embodiment 2 recombinant escherichia coli on the shake flask medium

[0044] The resulting genetically engineered bacteria were cultured overnight at 37°C in a 50mL medium containing 100μg / L ampicillin, and then inserted into a 50mL liquid medium containing 100μg / L ampicillin and cultured at 37°C until OD 600 =0.6, lower the temperature to 20°C and culture, add the inducer IPTG with a final concentration of 0.1mM to induce culture, centrifuge at 72h to obtain the supernatant enzyme liquid, which is the crude enzyme liquid, and measure the enzyme activity.

[0045] Five kinds of basal media were selected to compare the efficiency and yield of Escherichia coli fermented to produce keratinase in shake flasks. These five media are LB, 2×YT, SOC, TB, SB. The main differences of these five media are the presence or absence of carbon source and the concentration of different nitrogen sources or differences in salt ions.

[0046] LB (g / L): peptone...

Embodiment 3

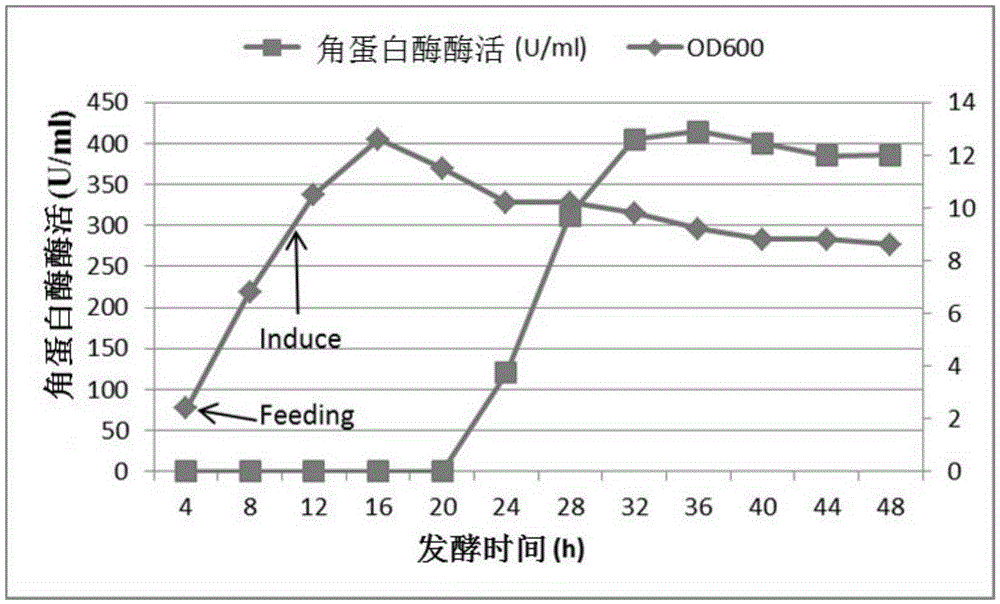

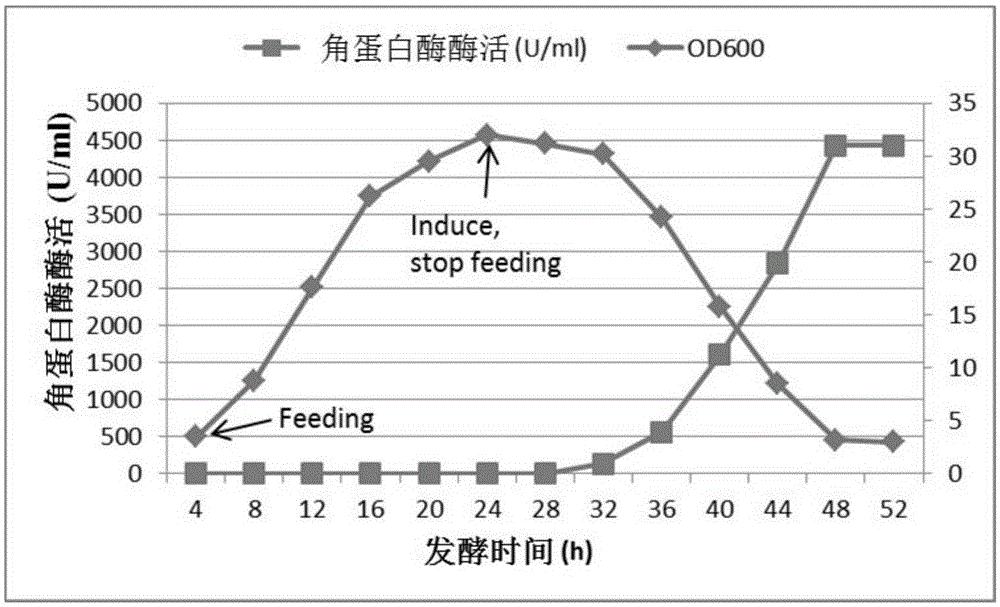

[0061] Embodiment 3 recombinant escherichia coli produces keratinase on 3L fermenter

[0062] 3L fermenter fermentation conditions: initial culture temperature 37°C, inoculum size 2%, ampicillin content 100 μg / l, stirring speed 400-800rpm, initial liquid volume 1L, ventilation volume 1vvm, using BioFlo / CelliGen115 fermenter from New Brunswick Company.

[0063] On the basis of 2×YT medium, carbon source medium (g / l, glycerol 500, yeast powder 15, peptone 30, MgSO 4 15), and feed the dissolved oxygen when it rebounds for the first time, and the flow speed is 0.8ml / min. When the cell concentration reached 10OD600, IPTG was added to a final concentration of 200mM for low-temperature induction at 20°C, during which the pH of the medium was controlled by adding ammonia water to not less than 7.0. The experimental results show that (such as figure 2 ), using fed-batch strategy, Escherichia coli can indeed reach 12.6OD in 16h 600 , but 6 hours after the induction, the bacterial ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com