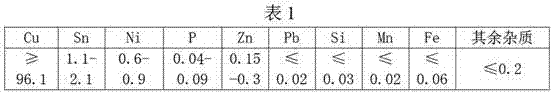

A kind of preparation method of cu-ni-sn copper alloy strip

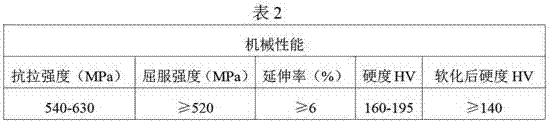

A copper alloy plate, cu-ni-sn technology, applied in the field of copper alloy, can solve the problem that the tensile strength, yield strength and hardness of copper alloy cannot meet the requirements of production standards, so as to improve the melting and casting process, increase the strength and reduce the number of products The effect of stomata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preparation method of TKA copper alloy strip, comprises the steps:

[0022] (1) According to the effective volume of the power frequency cored induction furnace, the mass ratio is copper: tin: nickel: phosphorus: zinc = 97.43: 1.5: 0.8: 0.07: 0.2 for batching; copper, tin, nickel, phosphor copper Put the intermediate alloy and zinc into the furnace body of the power frequency cored induction furnace and heat it to 1170-1210°C (1170°C, 1190°C, 1210°C) for melting, and then cover the surface of the melt with a layer of calcined charcoal with a thickness of 150-200mm , keep warm for 30 minutes, and then fully stir to obtain smelting water (smelting water is also called copper water);

[0023] (2) Use a crystallizer with a graphite inner sleeve to carry out the above-mentioned copper water at a temperature of 1170°C-1210°C (1170°C, 1190°C, 1210°C), and a casting speed of 2.4-3.0 m / h (2.4 m / h, 2.7 m / h, 3.0 m / h) semi-continuous casting process to obtain a rectangular ing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com