Diamond substrate based nitride structure, preparation method and semiconductor device

A technology of diamond and nitride, which is applied in the field of semiconductor devices, can solve the problems of large nitride epitaxial layer mismatch, large thermal resistance at the interface of the diamond substrate, complex process, etc., to achieve good crystal quality, reduce lattice mismatch, Effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

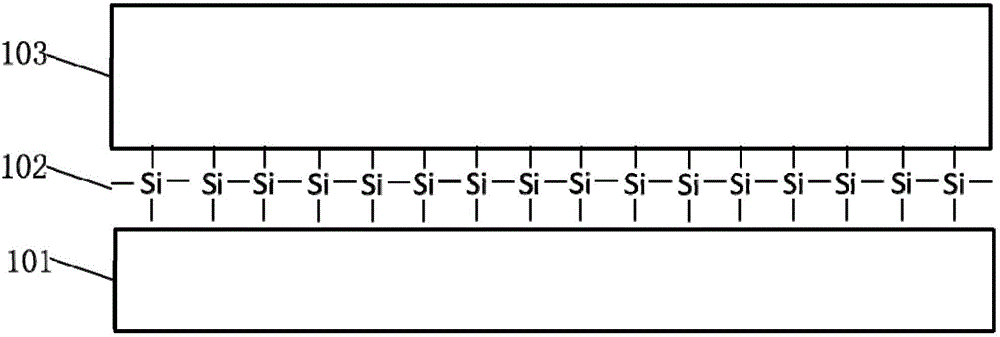

[0044] figure 1 is a schematic cross-sectional view of the nitride structure provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the structure includes a diamond substrate 101 ; at least one group IV atomic layer 102 on the diamond substrate 101 ; and a nitride epitaxial layer 103 on the at least one group IV atomic layer 102 .

[0045] The above-mentioned diamond substrate 101 is relatively thick, which is different from the diamond prepared by MOCVD method on nitride, and it is not easy to warp, and will not cause excessive warping of the epitaxial wafer, so it is not necessary to use polishing and other means to solve the problem of the diamond substrate 101. The problem of warping is simple, and the thermal resistance of diamond is small, and the thermal conductivity is good. The specific thickness of the diamond substrate 101 can be adjusted according to the design requirements of the nitride structure.

[0046] In addition, the group IV atoms...

Embodiment 2

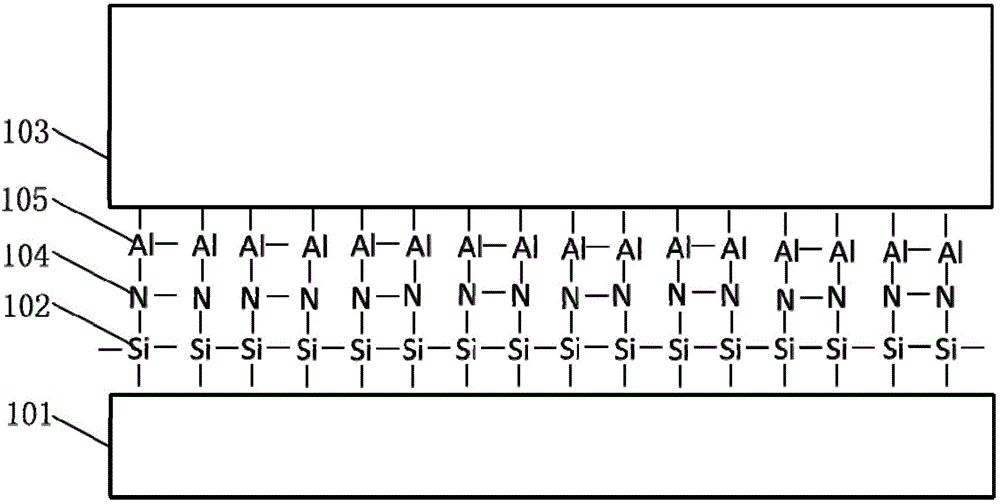

[0055] figure 2 It is a schematic cross-sectional view of the nitride structure provided by Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments, and the difference from Embodiment 1 is that there are sequentially stacked group V atomic layers 104 and III group atomic layer 105. Such as figure 2 As shown, the structure includes a diamond substrate 101; at least one IV group atomic layer 102 on the diamond substrate 101; a V group atomic layer 104 on the at least one IV group atomic layer 102; Group III atomic layer 105 above, and nitride layer 103 above group III atomic layer 105 .

[0056] Likewise, the aforementioned group IV atom may be a silicon atom. The atoms in the group V atomic layer 104 may be N, and the atoms in the group III atomic layer 105 may be Al. The group V atomic layer 104 and the group III atomic layer 105 can more smoothly transition the diamond substrate 101 from at least one group IV ...

Embodiment 3

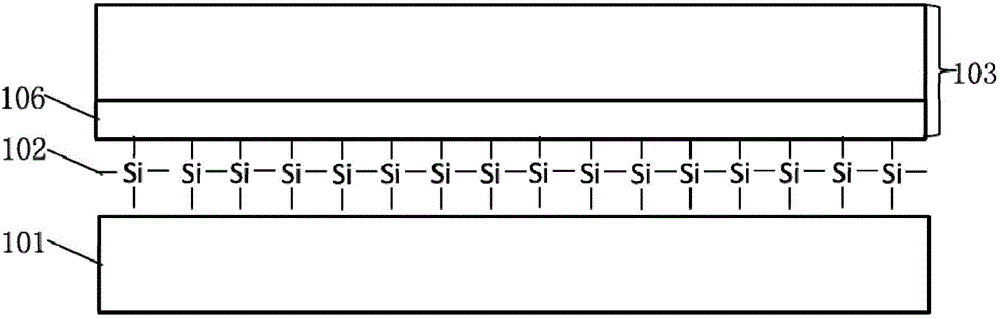

[0069] image 3 It is a schematic cross-sectional view of the nitride structure provided by Embodiment 3 of the present invention. This embodiment is optimized based on the first embodiment, and the difference from the first embodiment is that the nitride epitaxial layer 103 includes a nucleation layer 106 located on at least one group IV atomic layer 102 . Such as image 3 As shown, the structure includes a diamond substrate 101 ; at least one group IV atomic layer 102 on the diamond substrate 101 ; and a nucleation layer 106 on the at least one group IV atomic layer 102 . The group IV atoms in this embodiment may be Si, and the material of the nucleation layer 106 may be AlN, GaN or AlGaN. The nucleation layer 106 can transition at least one group IV atomic layer 102 to the nitride epitaxial layer 103 to improve the crystal quality of the nitride epitaxial layer 103 .

[0070] The preparation method of the nitride structure of the present embodiment is as follows:

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com