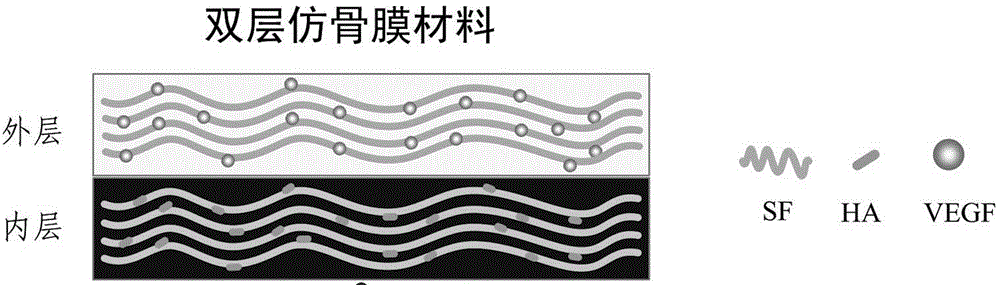

Preparation method of silk fibroin two-layer periosteum-imitation material

A silk fibroin, membrane material technology, applied in the field of biomaterials, can solve the problem of not simulating the structure and function of the periosteum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of outer layer spinning solution: after activation of VEGF (vascular endothelial growth factor), add VEGF / SF mass ratio of 2ng / mg to pure silk fibroin aqueous solution, stir and concentrate at 60°C to obtain SF with a concentration of 38% (Silk fibroin) / VEGF spinning solution;

[0024] (2) Preparation of the inner layer spinning solution: Add 0.1mol / L diammonium hydrogen phosphate aqueous solution to the silk fibroin aqueous solution with a concentration of 0.1%, then slowly add 0.1mol / L calcium nitrate solution, and adjust the pH= 10 or so, control the molar ratio of calcium to phosphorus to be 1.67, and control the mass ratio of silk fibroin to hydroxyapatite to be 0.2. After two hours of reaction, the solution is centrifuged to obtain a precipitate, which is then repeatedly washed with ethanol and freeze-dried to obtain SF / HA ( Hydroxyapatite) nanoparticles, and then add SF / HA nanoparticles to SF aqueous solution, stir and concentrate at 60°C to obtai...

Embodiment 2

[0028] (1) Preparation of outer layer spinning solution: after activation of VEGF (vascular endothelial growth factor), add VEGF / SF mass ratio of 10ng / mg to pure silk fibroin aqueous solution, stir and concentrate at 60°C to obtain SF with a concentration of 40% (Silk fibroin) / VEGF spinning solution;

[0029] (2) Preparation of the inner layer spinning solution: Add 0.1mol / L diammonium hydrogen phosphate aqueous solution to the silk fibroin aqueous solution with a concentration of 0.1%, then slowly add 0.1mol / L calcium nitrate solution, and adjust the pH= 10 or so, control the molar ratio of calcium to phosphorus to be 1.67, and control the mass ratio of silk fibroin to hydroxyapatite to be 0.2. After two hours of reaction, the solution is centrifuged to obtain a precipitate, which is then repeatedly washed with ethanol and freeze-dried to obtain SF / HA ( Hydroxyapatite) nanoparticles, and then add SF / HA nanoparticles to SF aqueous solution, stir and concentrate at 60°C to obta...

Embodiment 3

[0033](1) Preparation of outer layer spinning solution: after activation of VEGF (vascular endothelial growth factor), add VEGF / SF mass ratio of 20ng / mg to pure silk fibroin aqueous solution, stir and concentrate at 60°C to obtain SF with a concentration of 40% (Silk fibroin) / VEGF spinning solution;

[0034] (2) Preparation of the inner layer spinning solution: Add 0.1mol / L diammonium hydrogen phosphate aqueous solution to the silk fibroin aqueous solution with a concentration of 0.1%, then slowly add 0.1mol / L calcium nitrate solution, and adjust the pH= 10 or so, control the molar ratio of calcium to phosphorus to be 1.67, and control the mass ratio of silk fibroin to hydroxyapatite to be 0.2. After two hours of reaction, the solution is centrifuged to obtain a precipitate, which is then repeatedly washed with ethanol and freeze-dried to obtain SF / HA ( Hydroxyapatite) nanoparticles, and then add SF / HA nanoparticles to SF aqueous solution, stir and concentrate at 60°C to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com