Preparation method of dibasic ester aromatic ring saturation catalyst containing benzene ring

A catalyst, a technology of benzene dibasic acid, which is applied in the field of preparation of dibasic ester aromatic ring saturated catalysts, can solve the problem of deactivation of active components, and achieve the effect of improving reaction efficiency and precious metal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

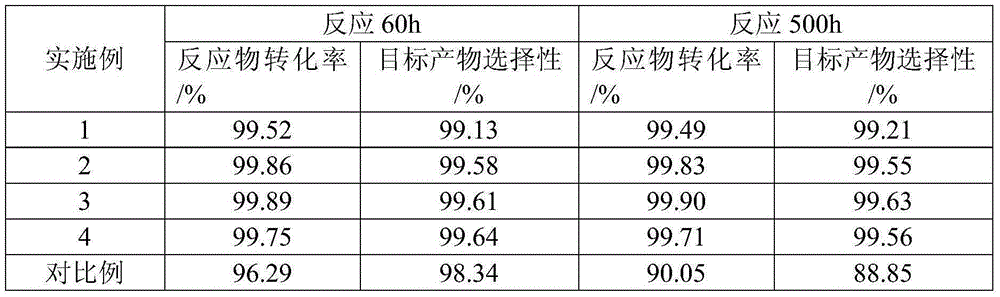

Examples

Embodiment 1

[0019] Take amorphous silica-alumina powder and macroporous silica gel and mix appropriate amount of alumina binder to extrude into strips. After drying and roasting, the specific surface area of the carrier is 105cm 2 / g, the total pore volume is 2.0ml / g. Take an appropriate amount of ruthenium acetate powder, dissolve it in an appropriate amount of acetic acid solution, slowly add dilute ammonia solution dropwise until the pH of the solution reaches 9.5, impregnate an appropriate amount of carrier in it, after saturated adsorption, immediately put it in an oven to dry at 80°C for 18h, and then roast at 300°C for 3h. The results of X-ray fluorescence analysis show that the content of elemental Ru accounts for 0.3%wt of the catalyst, and the content of Cl element is less than 0.02%wt.

Embodiment 2

[0021] Take an appropriate amount of macroporous alumina dry powder (dry basis accounts for 90%) and alumina binder (dry basis accounts for 10%) to extrude into strips, and after drying and roasting, the specific surface area of the carrier is 193cm 2 / g, the total pore volume is 1.31ml / g. Take an appropriate amount of ruthenium acetate powder, dissolve it in an appropriate amount of ethanol solution, slowly add dilute ammonia solution dropwise until the pH of the solution reaches 8.5, impregnate an appropriate amount of carrier in it, after saturated adsorption, immediately put it in an oven for drying at 60°C for 18 hours, and roast at 300°C for 3 hours. The results of X-ray fluorescence analysis show that the content of elemental Ru accounts for 0.8%wt of the catalyst, and the content of Cl element is less than 0.02%wt.

Embodiment 3

[0023] Take macroporous alumina powder (30% on dry basis) and alumina A101 powder (70% on dry basis) to extrude into strips, after drying and roasting, the specific surface area of the carrier is 218cm 2 / g, the total pore volume is 0.79ml / g. Take an appropriate amount of ruthenium acetate powder, dissolve it in an appropriate amount of ethanol solution, slowly add dilute ammonia solution dropwise until the pH of the solution reaches 8.0, impregnate an appropriate amount of carrier in it, after saturated adsorption, immediately put it in an oven for drying at 60°C for 18 hours, and then roast at 300°C for 3 hours. The results of X-ray fluorescence analysis show that the content of elemental Ru accounts for 0.8%wt of the catalyst, and the content of Cl element is less than 0.02%wt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com