A method for preparing graphene by composite shear stress exfoliation using vibrating screw extruder

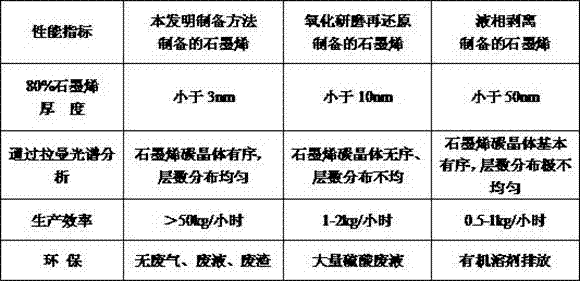

A technology of screw extruder and shear stress, which is applied in the field of preparation of graphene by compound shear stress exfoliation of vibrating screw extruder, which can solve the problem of difficult to overcome van der Waals force of graphite layer, difficulty in controlling the number of graphene layers, and long reaction time and other issues, to achieve the effect of preserving lattice integrity, efficient preparation, and stripping time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Combine graphite with excess intercalant C 12 The long-chain organic quaternary ammonium salt is added into water, homogeneously dispersed for 10 minutes, then repeatedly washed with deionized water and filtered to obtain a graphite filter cake;

[0037] (2) Disperse and mix the dried graphite filter cake in step (1) with sodium stearate and sulfamic acid at 80-120°C for 30 minutes. The mass ratio of graphite filter cake, sodium stearate and sulfamic acid 100:1:0.5;

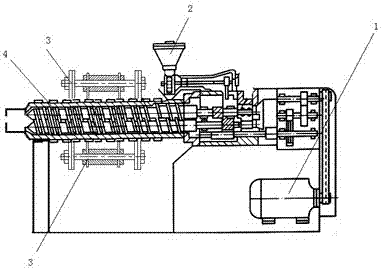

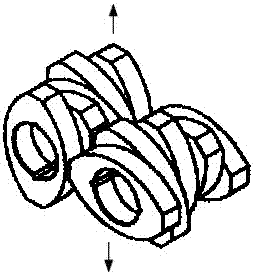

[0038] (3) Send the mixture obtained in step (2) into a co-rotating twin-screw electromagnetic dynamic extruder. The temperature of the vibrating extruder is set at 300-400°C, the speed is 800rpm, the vibration frequency is 80Hz, and the amplitude is 0.1mm. Among them, the screw of the extruder is composed of the staggered angles between the meshing blocks of 30°, 45°, 60°, 90°, reverse 30°, reverse 45°, reverse 60°, through the high-speed rotating shear force field and vibration pull Extensive force...

Embodiment 2

[0041] (1) Combine graphite with excess intercalant C 16 The long-chain organic quaternary ammonium salt was added to water, homogeneously dispersed for 25 minutes, then repeatedly washed with deionized water and filtered to obtain a graphite filter cake;

[0042] (2) Disperse and mix the dried graphite filter cake in step (1) with calcium stearate and sodium polyaspartate at 80-120°C for 45 minutes. The mass ratio of sodium aspartate is 100:1.5:1;

[0043] (3) Send the mixture obtained in step (2) into a co-rotating four-screw ultrasonic vibration extruder. The temperature of the vibration extruder is set at 300-400°C, the speed is 1200rpm, the ultrasonic frequency is 20kHz, and the power is continuously adjustable at 2KW. Through the high-speed rotating shear force field and the ultrasonic vibration tension field, the graphite is sheared and exfoliated to obtain graphene.

Embodiment 3

[0045] (1) Combine graphite with excess intercalant C 18 The long-chain organic diamine is added into water, homogeneously dispersed for 10 minutes, then repeatedly washed with deionized water and filtered to obtain a graphite filter cake;

[0046] (2) Disperse and mix the dried graphite filter cake in step (1) with zinc stearate and diethylthiourea at 80-120°C for 35 minutes. The mass ratio of urea is 100:1:0.5;

[0047] (3) Send the mixture obtained in step (2) into a co-rotating three-screw longitudinal mechanical vibrating extruder. The temperature of the vibrating extruder is set at 300-400°C, the speed is 600rpm, the frequency is set at 50Hz, and the amplitude is 3mm. Graphene is obtained by shearing and exfoliating graphite through a high-speed rotating shear force field and a vibrating tension force field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com