Electric flocculation method for pretreating high-concentration polluted wastewater of glyphosate

A glyphosate, high-concentration technology, applied in the direction of water pollutants, natural water treatment, water/sewage treatment, etc., to achieve the effect of fast speed, clear and transparent effluent, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

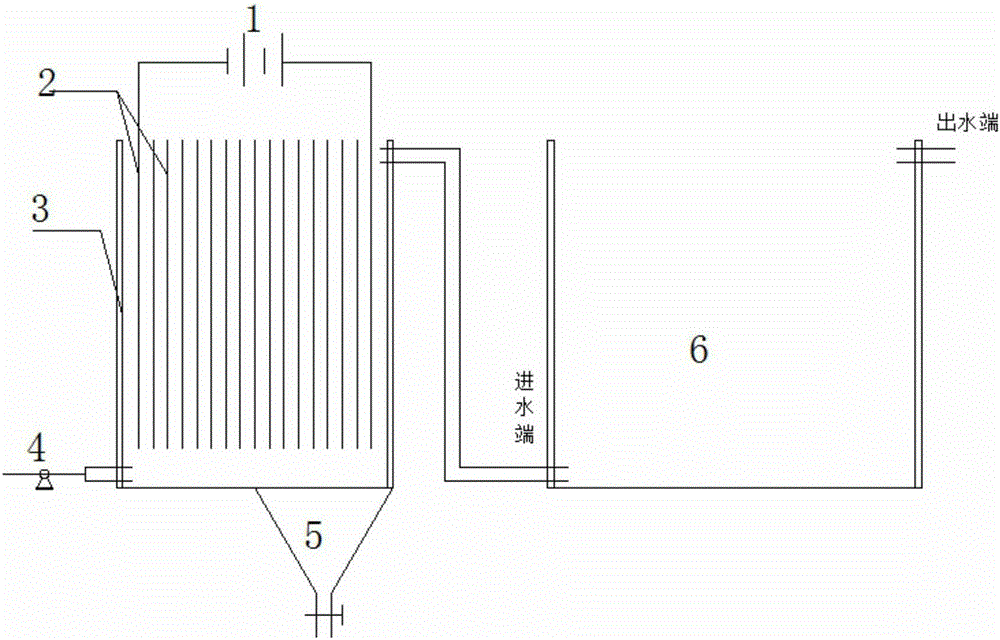

[0031] like figure 1 Shown is a schematic diagram of equipment for pretreatment of high-concentration glyphosate wastewater by electrocoagulation technology. The pulse power supply 1 is set above the reaction tank 3, the aluminum plate 2 is vertically placed in the reaction tank 3, the pump 4 is set at the lower end of the reaction tank 3, the mud discharge bucket 5 is set at the bottom of the reaction tank 3, and the bottom of the sedimentation tank 6 is connected to the bottom of the reaction tank 3. The upper end of the reaction tank 3 is connected by a water pipe.

[0032] The pump 4 is set at the lower end of the reaction tank 3, so that the reaction tank 3 adopts the water flow mode of the bottom end and the upper end of the water outlet, the aluminum plate 2 is vertically placed in the reaction tank 3, and the direction of the water flow is opposite to the direction of the floc precipitation produced by the electrolytic reaction. It can increase the contact time betwee...

Embodiment 2

[0040] After filtering the glyphosate wastewater, adjust the pH value to 7.0, and install it in the electrolytic cell with a surface area of 176cm 2 Aluminum plates with a spacing of 10mm. Turn on the pump to pass the wastewater into the electrolyzer and start the pulse power supply at the same time, adjust the current density to 8.52mA / cm 2 , start the electrolytic reaction, adjust the flow rate and set the reaction time to 15min. Leave the water to settle for 30 minutes to scrape off the foam on the liquid surface and remove the sludge at the bottom. The supernatant water discharged is the pretreated drainage.

[0041] Processing effect two:

[0042] Using the electrocoagulation pretreatment method of glyphosate high-concentration wastewater of the present invention, another kind of glyphosate high-concentration polluted wastewater is pretreated, and the treatment effect is as shown in Table 2:

[0043] Table 2

[0044]

[0045] As can be seen from Table 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com