A kind of nano-suspension concrete early strength agent and preparation method thereof

A nano-suspension and concrete technology, applied in the field of nano-technology-based concrete early-strength agent and its preparation, and early-strength concrete admixture, can solve problems such as insufficient early-strength effect, decreased concrete durability, and complicated preparation process. Achieve the effect of being conducive to active excitation, excellent early strength performance, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] (1) Preparation of polymer dispersant

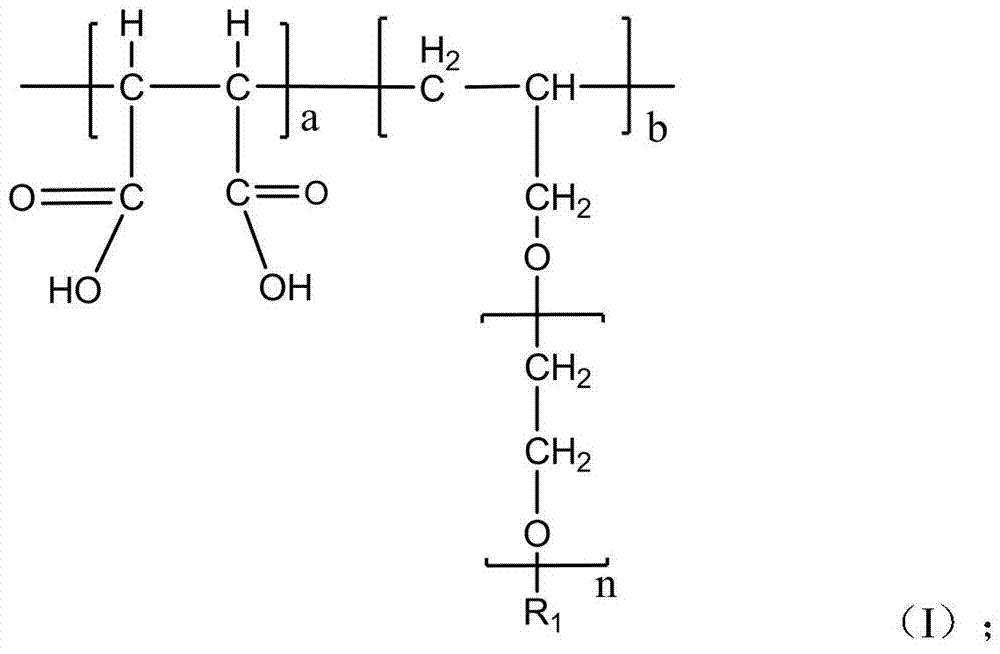

[0021] Prepare the polymer with molecular formula (I) according to Chinese patent 20110393582.0, and without neutralization, its molecular formula is:

[0022]

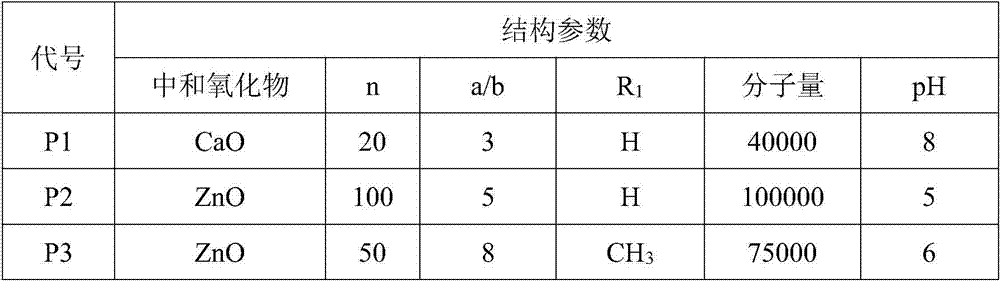

[0023] The above polymer solution was neutralized with calcium oxide or zinc oxide to obtain a polymer dispersant with a solid content of 40%, as shown in Table 1.

[0024] Table 1 Parameters and codes of polymer dispersants

[0025]

[0026] (2) Preparation of nano-suspension concrete early strength agent

[0027] The solution that the high molecular polymer dispersant that step (1) makes and soluble calcium salt, soluble zinc salt, soluble aluminum salt is formed adds in the there-necked flask of 500ml, under the condition of 10-20 ℃, stirs rapidly; Then put The soluble silicate is formulated into an aqueous solution, which is slowly added dropwise to the above mixed solution for 5-8 hours. Concrete preparation example is as follows:

preparation Embodiment 1

[0029] In a 500mml three-necked flask, 75g P1, 11.8g Ca(NO 3 ) 2 4H 2 O, 19.0gAl(NO 3 ) 3 9H 2 O, 7.5gZnNO 3 ·7H 2 O was dissolved into 136.7g of water, and then Na with a mass concentration of 5.7% 2 SiO 3 9H 2 Add 250 g of O sodium silicate solution dropwise to the mixed solution for 8 hours, and keep the temperature of the solution at 18° C. during the dropwise addition.

preparation Embodiment 2

[0031]In a 500mml three-necked flask, 100g P3, 11.3g Ca(NO 2 ) 2 2H 2 O), 15.0g (Al(NO 3 ) 3 9H 2 O, 6.0g ZnNO 3 ·7H 2 O was dissolved into 167.7g of water, and then the mass concentration was 7.2% Na 2 SiO 3 9H 2 Add 200 g of O sodium silicate solution dropwise to the mixed solution for 6 hours, and keep the solution temperature at 20°C during the dropwise addition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com