A kind of in-situ reinforced and toughened urea-formaldehyde resin molding compound and its preparation method

A technology for strengthening and toughening urea-formaldehyde resin, applied in the field of in-situ strengthening and toughening urea-formaldehyde resin molding compound and its preparation field, can solve the problems of difficulty in strengthening and toughening modification of urea-formaldehyde resin molding compound, limited strengthening and toughening effect, etc. The effect of curing cross-linking point, increasing strength and improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

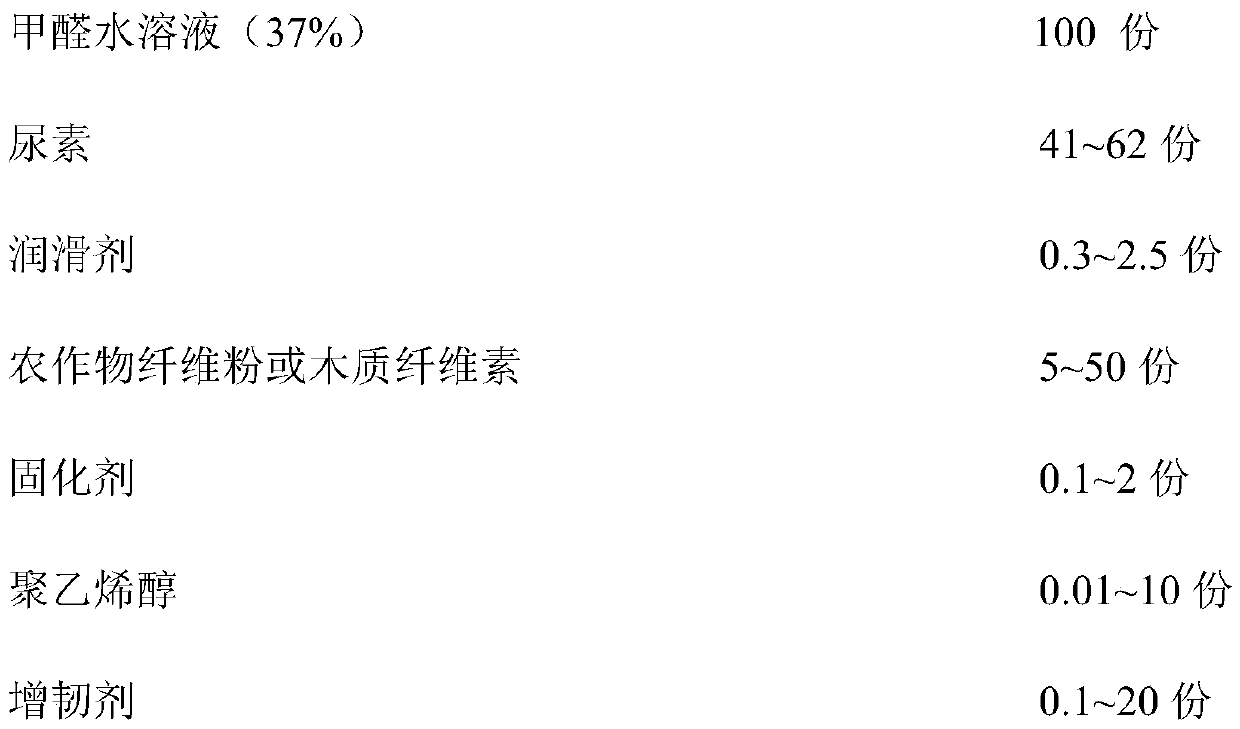

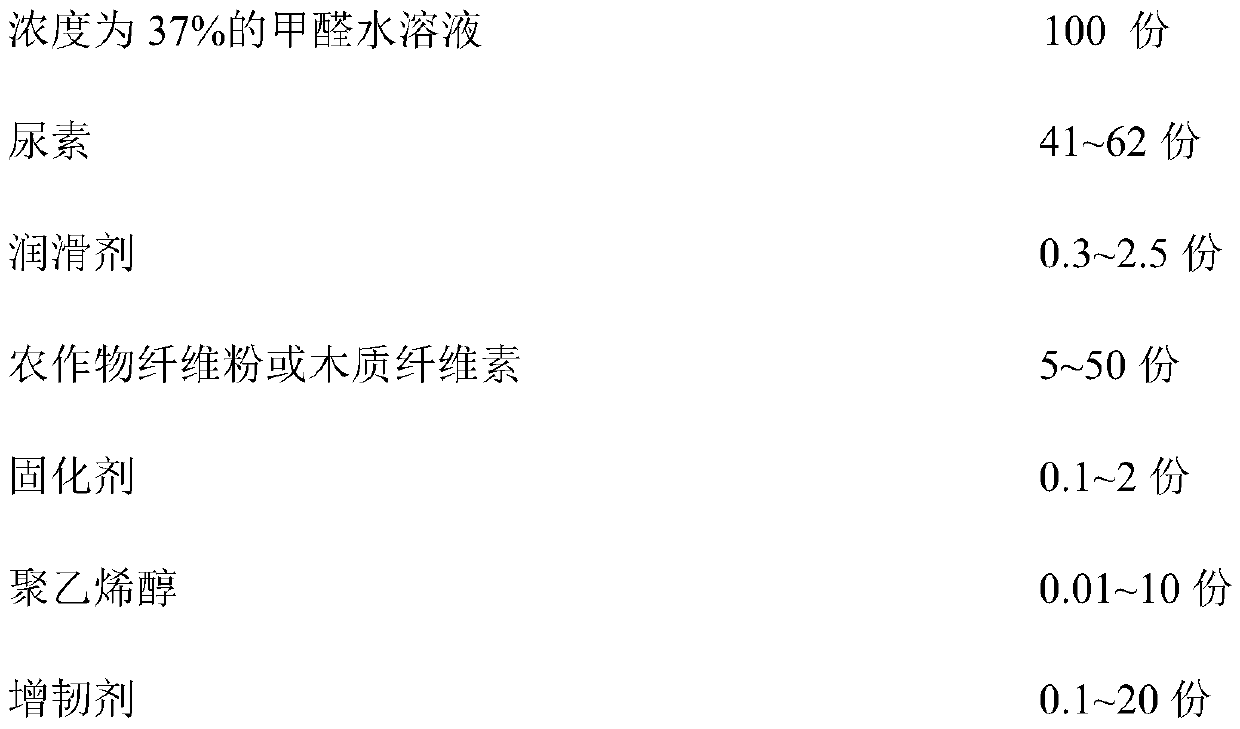

Method used

Image

Examples

Embodiment 1

[0023] Take 0.5 part of polyvinyl alcohol with a degree of polymerization of 1000 and a degree of alcoholysis of 88%, dissolve it in distilled water at 95°C for 3 hours, configure it into a 15% aqueous solution, and cool it to room temperature for use; then control the temperature of the reactor to 20 ℃, put 100 parts of formaldehyde, polyvinyl alcohol aqueous solution and 5 parts of polyether polyurethane in the reaction kettle, stir and react for 20 minutes, then add 50 parts of urea, continue stirring and reacting for 30 minutes; finally add 1.5 parts of stearic acid / stearic acid Mixture of amide / polypropylene glycol, 30 parts of corn stalk powder, 0.2 parts of curing agent ammonium chloride and diammonium hydrogen phosphate, after the system is fully mixed, close the reactor, turn on the vacuum, and heat up the reactor to 95°C; knead After drying for 250 minutes, remove the vacuum, cool and pulverize to obtain a reinforced and toughened urea-formaldehyde resin molding compo...

Embodiment 2

[0026] Take 8 parts of polyvinyl alcohol with a degree of polymerization of 2400 and a degree of alcoholysis of 88%, dissolve it in distilled water at 95°C for 3 hours, configure it into a 5% aqueous solution, and cool it to room temperature for use; then control the temperature of the reactor to 80 ℃, put 100 parts of formaldehyde, polyvinyl alcohol aqueous solution and 10 parts of amino-terminated polyether in the reactor, stir for 50 minutes, add 40 parts of urea, continue stirring for 60 minutes; finally add 2 parts of zinc stearate / stearic acid Amide / calcium stearate mixture, 10 parts of lignocellulose, 0.5 parts of curing agent p-toluenesulfonic acid, after the system is fully mixed, close the reaction kettle, turn on the vacuum, and heat the reaction kettle to 60°C; knead and dry for 300 minutes Finally, remove the vacuum, cool and pulverize to obtain a reinforced and toughened urea-formaldehyde resin molding compound.

[0027] Compared with the original urea-formaldehy...

Embodiment 3

[0029] Take 10 parts of polyvinyl alcohol with a degree of polymerization of 2000 and a degree of alcoholysis of 99%, dissolve it in distilled water at 95°C for 3 hours, configure it into a 5% aqueous solution, and cool it to room temperature for use; then control the temperature of the reactor to 50 ℃, put 100 parts of formaldehyde, polyvinyl alcohol aqueous solution and 20 parts of amino-terminated liquid nitrile rubber in the reaction kettle, add 60 parts of urea after stirring for 90 minutes, continue stirring and reacting for 60 minutes; finally add 2.5 parts of zinc stearate / polyethylene A mixture of propylene glycol, 40 parts of lignocellulose, and 0.1 part of curing agent ammonium sulfamate. After the system is fully mixed, close the reactor, turn on the vacuum, and the temperature of the reactor is raised to 70°C; after kneading and drying for 60 minutes, remove the vacuum, cool, Grinding to obtain reinforced and toughened urea-formaldehyde resin molding compound.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com