High-elasticity epoxy resin encapsulating material and preparation method thereof

A technology of epoxy resin and potting materials, which is applied in the field of potting materials, can solve problems such as complex preparation process conditions, high manufacturing costs, and insufficient elasticity, and achieve the effects of simple preparation methods, improved mechanical properties, and improved elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

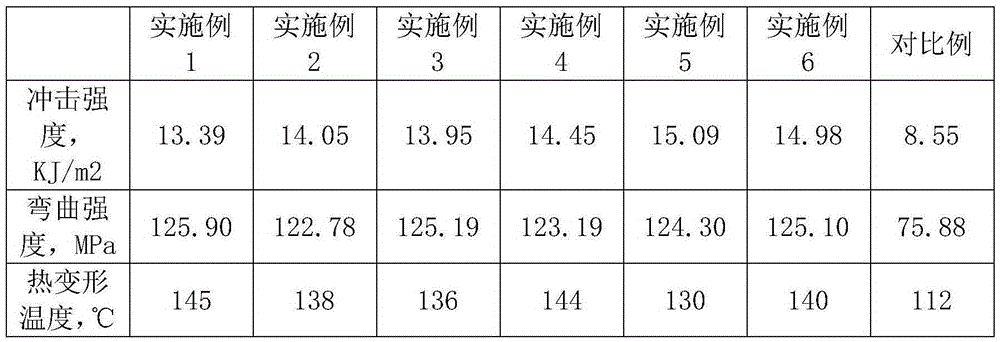

Examples

Embodiment 1

[0035] A high elasticity epoxy resin potting material, in parts by weight, comprises the following components:

[0036] 30 parts of epoxy resin, 2 parts of polypropylene fiber,

[0037] 10 parts of polymethyl methacrylate,

[0038] 5 parts of carboxyl-terminated polybutadiene-acrylonitrile,

[0039] 1 part of precipitated silica, 5 parts of active diluent,

[0040] 1 part of crosslinking agent, 3 parts of curing agent.

[0041] Its preparation method comprises the following steps:

[0042] (1) Add epoxy resin, polymethyl methacrylate and carboxyl-terminated polybutadiene-acrylonitrile into a high-speed kneader, and knead at 40-50°C for 30 minutes to obtain a mixture 1;

[0043] (2) Mix and stir the precipitated silica, polypropylene fiber, reactive diluent and crosslinking agent evenly, and ultrasonically stir for 1 hour at a power of 500W to obtain a uniform dispersion;

[0044] (3) Mix the mixed material 1 obtained in step (1) with the uniform dispersion and curing agen...

Embodiment 2

[0046] A high elasticity epoxy resin potting material, in parts by weight, comprises the following components:

[0047] 60 parts of epoxy resin, 5 parts of polypropylene fiber,

[0048] 15 parts of polymethyl methacrylate,

[0049] 10 parts of carboxyl-terminated polybutadiene-acrylonitrile,

[0050] 3 parts of precipitated silica, 12 parts of active diluent,

[0051] 5 parts of crosslinking agent, 7 parts of curing agent.

[0052] Its preparation method comprises the following steps:

[0053] (1) Add epoxy resin, polymethyl methacrylate and carboxyl-terminated polybutadiene-acrylonitrile into a high-speed kneader, and knead at 40-50°C for 60 minutes to obtain a mixture 1;

[0054] (2) Mix and stir the precipitated silica, polypropylene fiber, reactive diluent and crosslinking agent evenly, and ultrasonically stir for 2 hours at a power of 800W to obtain a uniform dispersion;

[0055] (3) Mix the mixed material 1 obtained in step (1) with the uniform dispersion and curing...

Embodiment 3

[0057] A high elasticity epoxy resin potting material, in parts by weight, comprises the following components:

[0058] 40 parts of epoxy resin, 3 parts of polypropylene fiber,

[0059] 11 parts of polymethyl methacrylate,

[0060] 6 parts of carboxyl-terminated polybutadiene-acrylonitrile,

[0061] 1.5 parts of precipitated silica, 7 parts of reactive diluent,

[0062] 2 parts of crosslinking agent, 4 parts of curing agent.

[0063] Its preparation method comprises the following steps:

[0064] (1) Add epoxy resin, polymethyl methacrylate and carboxyl-terminated polybutadiene-acrylonitrile into a high-speed kneader, and knead at 40-50°C for 40 minutes to obtain a mixture 1;

[0065] (2) Mix and stir the precipitated silica, polypropylene fiber, reactive diluent and crosslinking agent evenly, and ultrasonically stir for 1.2h under the power of 600W to obtain a uniform dispersion;

[0066] (3) Mix the mixed material 1 obtained in step (1) with the uniform dispersion and cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com