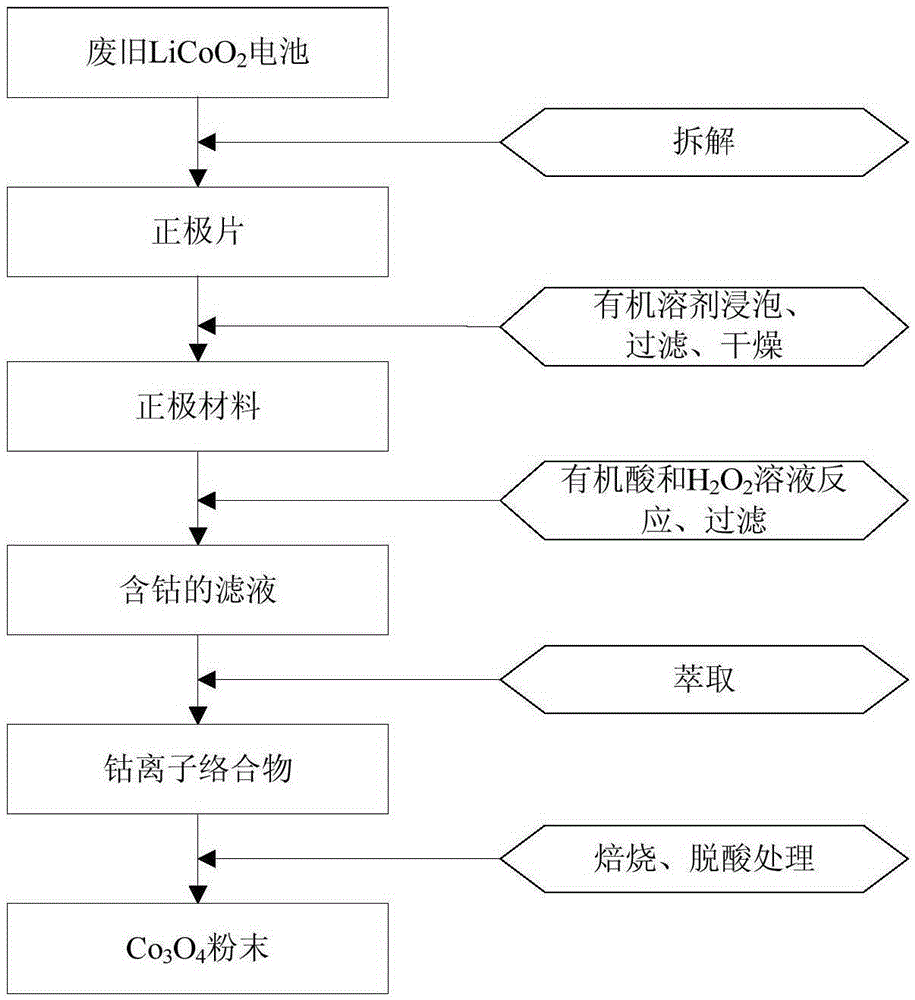

Method for recycling Co3O4 from positive electrode material of waste lithium cobalt oxide battery

A battery positive electrode and old lithium cobalt oxide technology, which is applied in the field of recycling waste lithium cobalt oxide battery positive electrode materials, can solve the problems of dust and heavy metal pollution, toxic and harmful gases, secondary pollution, etc., and achieve excellent material performance, stable chemical properties, Simple and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The spent LiCoO 2 The battery is broken and disassembled by hand, and the positive electrode sheet is taken out. Soak the above-mentioned positive electrode sheet in NMP solution, stir it mechanically for 10 min at room temperature with a solid-to-liquid ratio (g / ml) of 1:5, filter and dry to collect the black powder therein.

[0031] Take the black powder obtained in the separation stage, add citric acid for leaching, the amount of acid is 30g / l, add 1% H with a volume fraction of 1:1.5 2 o 2 , the solid-to-liquid ratio is controlled at 10g / l, stirred and leached at 30°C for 5h, and filtered to obtain a cobalt-containing filtrate.

[0032] Add tertiary carbon carboxylic acid Versatic911 to the filtrate and extract for 1 hour to obtain relatively pure Co ion complex.

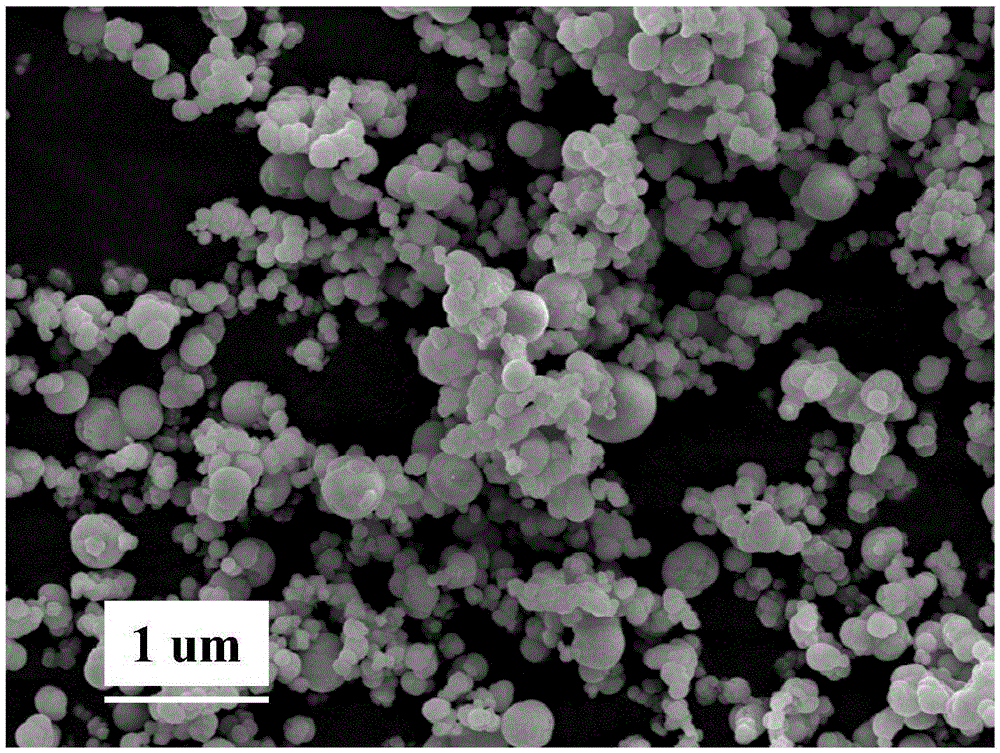

[0033] After extraction, the cobaltate leaching liquid is sent into the roasting furnace through a pneumatic feeding device, and air is blown in, the temperature of the heating area of the roasting f...

Embodiment 2

[0035] The spent LiCoO 2 The battery is broken and disassembled by hand, and the positive electrode sheet is taken out. Soak the above-mentioned positive electrode sheet in DMF solution, with a solid-to-liquid ratio (g / ml) of 1:15 at room temperature, with mechanical stirring for 30 minutes, filter and dry to collect the black powder therein.

[0036] Take the black powder obtained in the separation stage, add acetic acid for leaching, the amount of acid is 50g / l, add 1% H with a volume fraction of 1:2 2 o 2 , the solid-to-liquid ratio is controlled at 20g / l, stirred and leached at 60°C for 3h, and filtered to obtain a cobalt-containing filtrate.

[0037] Add bis(2-hydroxy-5-octyl)benzylamine to the filtrate and extract for 1 hour to obtain relatively pure Co ion complex.

[0038] After extraction, the cobaltate leaching liquid is sent to the roasting furnace through a pneumatic feeding device, and air is blown in to control the temperature of the heating area of the roas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com