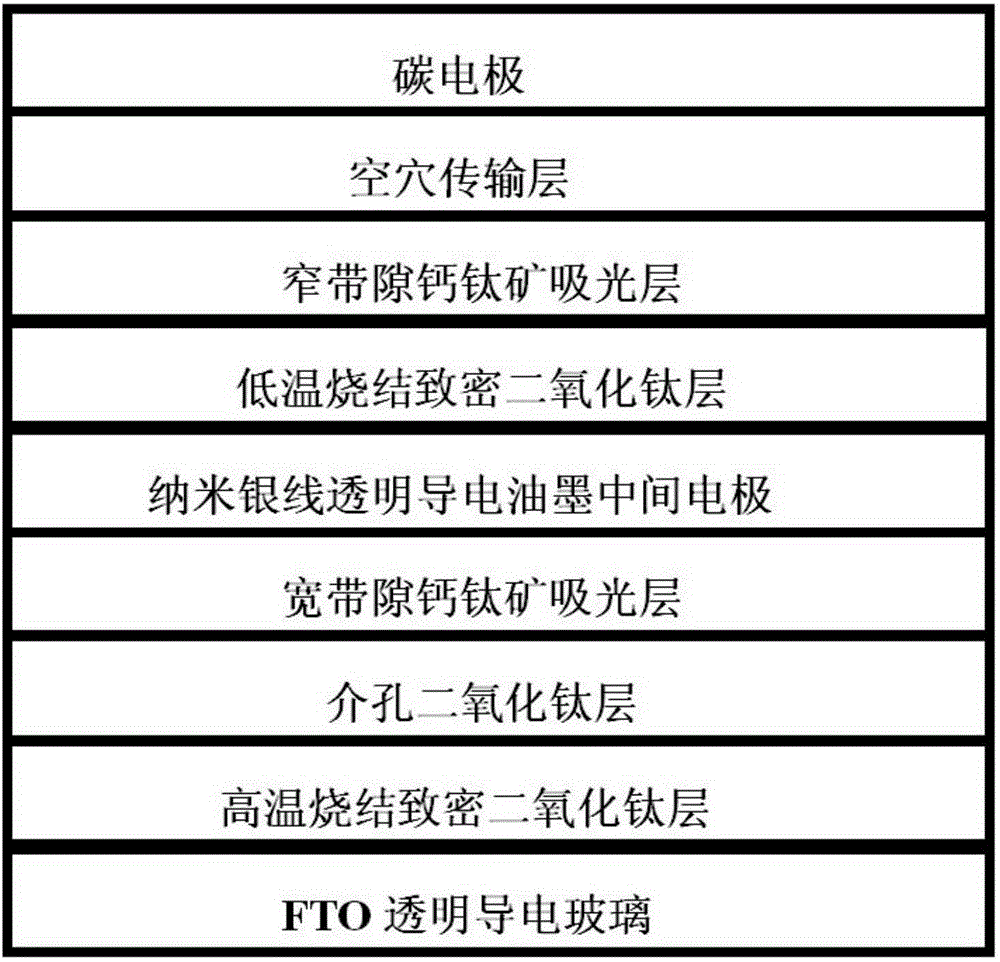

Integrated stack double-junction perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc. Through the effect of large loss, ultra-low energy consumption, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Cleaning FTO transparent conductive glass: FTO transparent conductive glass is ultrasonically cleaned with deionized water, acetone, and ethanol for 15 minutes, dried with nitrogen, and then treated with a UV ozone cleaner to remove residual organic matter;

[0027] (2) Preparation of titanium dioxide dense layer: use spray pyrolysis to deposit a titanium dioxide dense layer on cleaned FTO transparent conductive glass, and annealed at 500°C for 60 minutes to obtain a titanium dioxide dense layer with a thickness of 50nm;

[0028] (3) Preparation of wide band gap perovskite light-absorbing layer: preheated CsSnI with a mass percentage concentration of 40% at 75°C in a glove box 3 The solution (using dimethylformamide as the solvent) was spin-coated on the titanium dioxide mesoporous layer preheated at 120°C at a speed of 2500 rpm. During the spin-coating period, hot air was blown to the surface of the titanium dioxide mesoporous layer to obtain a thickness of 500 nm. The n...

Embodiment 2

[0035] (1) Cleaning transparent conductive FTO glass: FTO glass is ultrasonically cleaned with deionized water, acetone, and ethanol for 15 minutes in sequence, dried with nitrogen, and then treated with an ultraviolet ozone cleaner to remove residual organic matter;

[0036] (2) Preparation of titanium dioxide dense layer: use spray pyrolysis to deposit a titanium dioxide dense layer on cleaned FTO conductive glass, and anneal it at 500°C for 60 minutes to obtain a titanium dioxide dense layer with a thickness of 50 nm;

[0037] (3) Preparation of wide band gap perovskite light-absorbing layer: preheated CsSnI with a mass percentage concentration of 40% at 75°C in a glove box 3 The solution (using dimethylformamide as the solvent) was spin-coated on the titanium dioxide mesoporous layer preheated at 120°C at a speed of 2500 rpm. During the spin-coating period, hot air was blown to the surface of the titanium dioxide mesoporous layer to obtain a thickness of 500 nm. The narrow band ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com