Fenbendazole micro-capsules and preparation method thereof

A technology of fenbendazole microcapsules and fenbendazole, which is applied in the directions of microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of frequent medication, short elimination half-life, etc., and achieves improved fluidity and compressibility, reduced Incompatibility, effect of prolonging half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

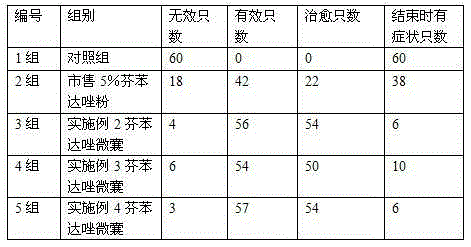

Examples

Embodiment 1

[0021] A fenbendazole microcapsule is prepared from the following raw materials in parts by weight: 1 part of fenbendazole, 2-6 parts of gum arabic, and 1-5 parts of gelatin.

[0022] The preparation method of fenbendazole microcapsules as described above comprises the following steps:

[0023] (1) Preparation of fenbendazole milk: Take 2-6 parts by weight of gum arabic and add it to 90-120 parts by weight of distilled water to dissolve, then add 1 part of fenbendazole and emulsify it in a tissue masher for 2-5 minutes, tissue The speed of the masher is 9000~12000r / min, standby;

[0024] (2) Preparation of gelatin solution: Take 1-5 parts by weight of gelatin and 100-140 parts by weight of distilled water to swell for 10-13 hours to make a sol, heat the sol at 45-60°C for 15-35 minutes, and filter to obtain a gelatin solution;

[0025] (3) Add the gelatin solution obtained in step (2) to the fenbendazole emulsion obtained in step (1), stir continuously, and add dropwise an ac...

Embodiment 2

[0028] The fenbendazole microcapsules provided by the invention are prepared from the following raw materials in parts by weight: 1 part of fenbendazole, 5 parts of gum arabic, and 5 parts of gelatin.

[0029] The above-mentioned fenbendazole microcapsules are prepared by the following steps.

[0030] (1) Preparation of fenbendazole milk: take 5g of gum arabic and add it to 100ml of distilled water to dissolve, then add 1g of fenbendazole and emulsify it in a tissue grinder for 3 minutes, the speed of the tissue grinder is 12000r / min, and set aside;

[0031] (2) Preparation of gelatin solution: Swell 5g gelatin and 100ml distilled water for 10 hours to make a sol, heat the sol at 50°C for 20 minutes, and filter to obtain a gelatin solution;

[0032] (3) Add the gelatin solution to the fenbendazole emulsion, stir continuously, and add dropwise acetic acid solution with a concentration of 15% by weight at 50°C to pH 3.9; stir and cool to 5°C in an ice-water bath, add weight 20m...

Embodiment 3

[0035] The fenbendazole microcapsules provided by the invention are prepared from the following raw materials in parts by weight: 1 part of fenbendazole, 5 parts of gum arabic, and 4 parts of gelatin.

[0036] The above-mentioned fenbendazole microcapsules are prepared by the following steps.

[0037] (1) Preparation of fenbendazole milk: Take 4 g of gum arabic and add it to 90 ml of distilled water to dissolve, then add 1 g of fenbendazole and emulsify in a tissue grinder for 4 minutes, the speed of the tissue grinder is 9000 r / min, and set aside;

[0038] (2) Preparation of gelatin solution: swell 4g gelatin and 120ml distilled water for 11 hours to make a sol, heat the sol at 55°C for 20 minutes, and filter to obtain a gelatin solution;

[0039] (3) Add the gelatin solution to the fenbendazole emulsion, stir continuously, and add dropwise acetic acid solution with a concentration of 15% by weight at 60°C to pH 4.1; stir and cool to 5°C in an ice-water bath, add weight Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com