High-activity catalyst regenerative liquid and preparation method thereof, and resurrection device

A high-activity catalyst and regeneration liquid technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as degradation of service characteristics, inability to maintain normal operation, and end of catalyst life. The effect of enhancing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

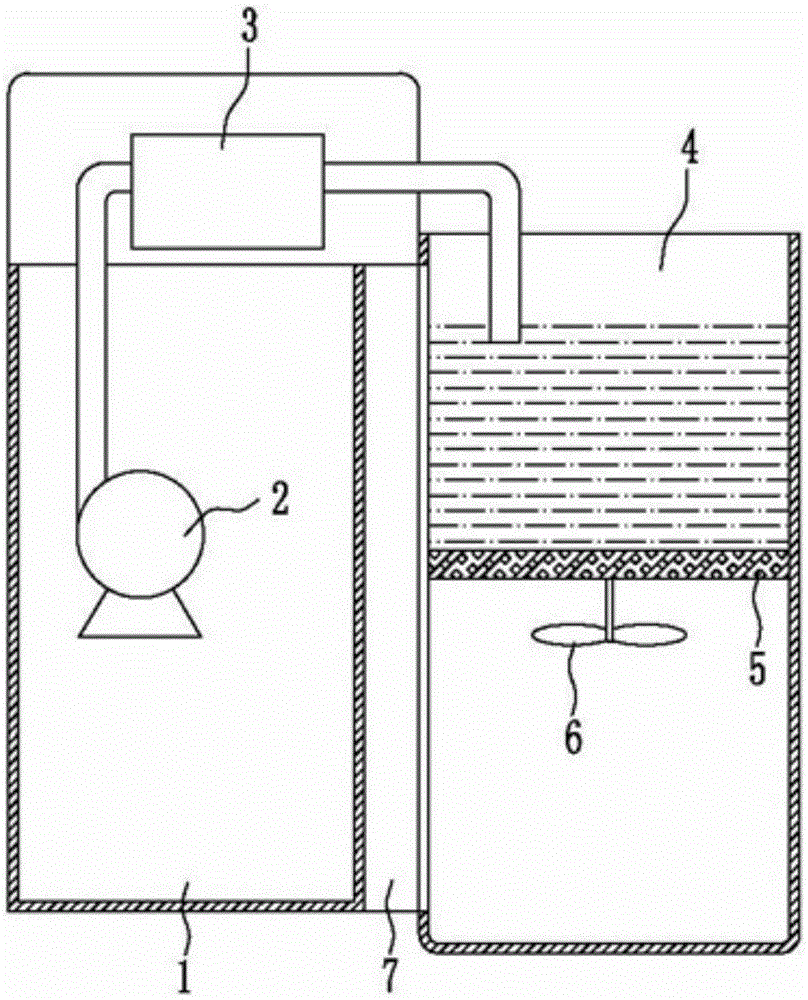

Image

Examples

Embodiment 1

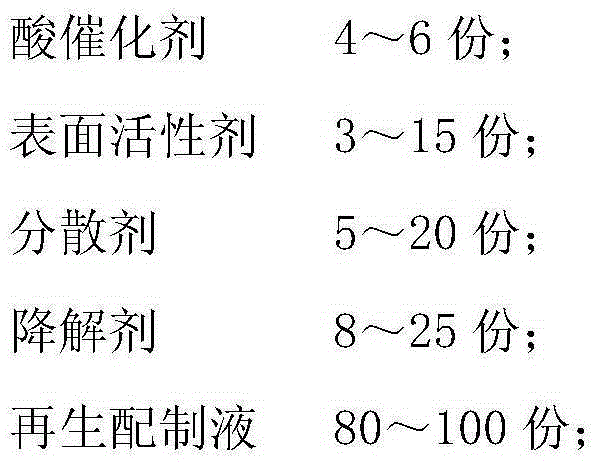

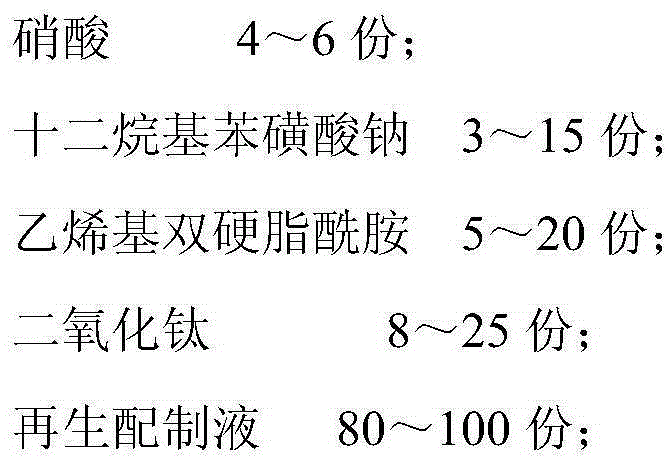

[0029] Highly active catalyst regeneration solution, including the following components by weight:

[0030]

[0031] Wherein, the regeneration preparation liquid includes sodium chloride and ethanol aqueous solution, the concentration of sodium chloride is 0.5 mol / l, and the concentration of ethanol aqueous solution is 60wt%.

[0032] The preparation method comprises the following steps:

[0033] (1) measure nitric acid and regeneration preparation solution, join nitric acid in regeneration preparation solution, mix completely, make A solution;

[0034] (2) Weigh sodium dodecylbenzene sulfonate, vinylbisstearamide and titanium dioxide respectively, first mix vinylbisstearamide and titanium dioxide completely, add to 60wt% ethanol aqueous solution and stir to dissolve, then add ten Sodium dialkylbenzene sulfonate, obtains the B solution that is equivalent to the volume of A solution;

[0035] (3) The solution A is added to the solution B by means of dropwise addition to ob...

Embodiment 2

[0037] Highly active catalyst regeneration solution, including the following components by weight:

[0038]

[0039] Wherein, the regeneration preparation liquid includes sodium sulfate and ethanol aqueous solution, the concentration of sodium sulfate is 2mol / l, and the concentration of ethanol aqueous solution is 50wt%.

[0040] The preparation method comprises the following steps:

[0041] (1) Measure sulfuric acid and regeneration preparation solution, join sulfuric acid in regeneration preparation solution, mix completely, make A solution;

[0042] (2) Take sodium lauryl sulfate, stearic acid monoglyceride and titanium dioxide respectively, first stearic acid monoglyceride and titanium dioxide are completely mixed, join in 50wt% ethanol aqueous solution and stir to dissolve, then add dodecane Sodium sulfate to prepare B solution, the volume ratio of A solution to B solution is 1~3:2;

[0043] (3) The solution A is added to the solution B by means of dropwise addition ...

Embodiment 3

[0045] Highly active catalyst regeneration solution, including the following components by weight:

[0046]

[0047] Wherein, the regeneration preparation liquid includes sodium chloride and ethanol aqueous solution, the concentration of sodium chloride is 1.5 mol / l, and the concentration of ethanol aqueous solution is 40wt%.

[0048] The preparation method comprises the following steps:

[0049] (1) Measure the hydrochloric acid and the regeneration preparation solution, add the hydrochloric acid to the regeneration preparation solution, mix completely, and prepare the A solution;

[0050] (2) Weigh polyethylene glycol, polyvinylpyrrolidone and titanium dioxide respectively, first mix polyvinylpyrrolidone and titanium dioxide completely, add to 40wt% ethanol aqueous solution and stir to dissolve, then add polyethylene glycol to prepare B solution, A The volume ratio of the solution to the B solution is 1 to 3:2;

[0051] (3) The solution A is added to the solution B by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com