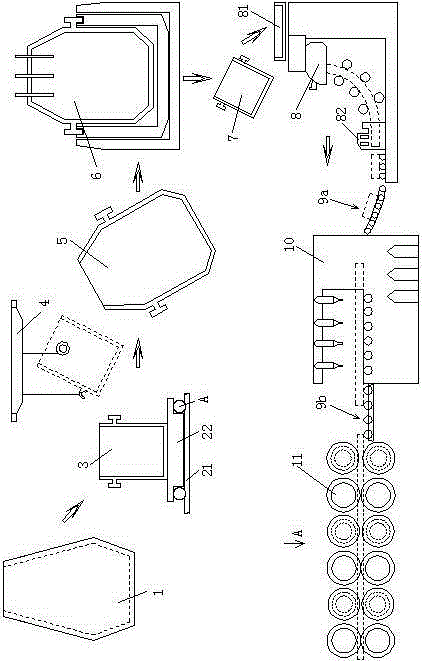

Blast furnace steelmaking continuous casting and rolling stainless steel round bar production system and production technology

A technology of steelmaking and continuous casting and production system, which is applied to furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of high cost and high energy consumption, and achieve the effects of simple production process, low energy consumption and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

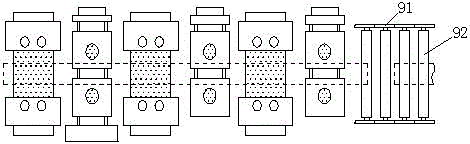

Method used

Image

Examples

Embodiment 1

[0030] A blast furnace steelmaking continuous casting and rolling stainless steel round bar production process comprises a blast furnace steelmaking continuous casting and rolling stainless steel round bar production system, comprising the following steps:

[0031] 1) Add anthracite, sintered nickel ore and coke into the blast furnace, the mass ratio is 6% of anthracite, 63% of sintered nickel ore, and 37% of coke, and feed rich oxygen into the blast furnace to smelt the additives into molten nickel iron, at the same time The tapping temperature of blast furnace is 1400℃;

[0032] 2) Transport the molten nickel iron smelted in step (1) into the AOD furnace through the ladle tank, and add lime, ferrosilicon, fluorite, high-carbon ferrochromium, electrolytic manganese and ferronickel into the AOD furnace, and the mass ratio is 6% lime, 1% ferrosilicon, 1% fluorspar, 20% high-carbon ferrochrome, 1% electrolytic manganese, 70% ferronickel, while oxygen, argon and nitrogen are intr...

Embodiment 2

[0037] A blast furnace steelmaking continuous casting and rolling stainless steel round bar production process comprises a blast furnace steelmaking continuous casting and rolling stainless steel round bar production system, comprising the following steps:

[0038] 1) Put anthracite, sintered nickel ore and coke into the blast furnace, the mass ratio is 9% of anthracite, 63% of sintered nickel ore, and 33% of coke, and feed rich oxygen into the blast furnace to smelt the additives into molten nickel iron, at the same time The blast furnace tapping temperature is controlled at 1440~1460°C;

[0039]2) Transport the molten nickel iron smelted in step (1) into the AOD furnace through the ladle tank, and add lime, ferrosilicon, fluorite, high-carbon ferrochromium, electrolytic manganese and ferronickel into the AOD furnace, and the mass ratio is 8% lime, 1.5% ferrosilicon, 1.5% fluorspar, 30% high-carbon ferrochrome, 1% electrolytic manganese, 60% ferronickel, while feeding oxygen,...

Embodiment 3

[0044] A blast furnace steelmaking continuous casting and rolling stainless steel round bar production process comprises a blast furnace steelmaking continuous casting and rolling stainless steel round bar production system, comprising the following steps:

[0045] 1) Add anthracite, sintered nickel ore and coke into the blast furnace, the mass ratio is 7.5% of anthracite, 60% of sintered nickel ore, and 33% of coke, and feed rich oxygen into the blast furnace to smelt the additives into molten nickel iron, at the same time The blast furnace tapping temperature is controlled at 1500°C;

[0046] 2) Transport the molten nickel iron smelted in step (1) into the AOD furnace through the ladle tank, and add lime, ferrosilicon, fluorite, high-carbon ferrochromium, electrolytic manganese and ferronickel into the AOD furnace, and the mass ratio is 7% lime, 1.2% ferrosilicon, 1.3% fluorspar, 25% high-carbon ferrochrome, 6% electrolytic manganese, 65% ferronickel, while feeding oxygen, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com