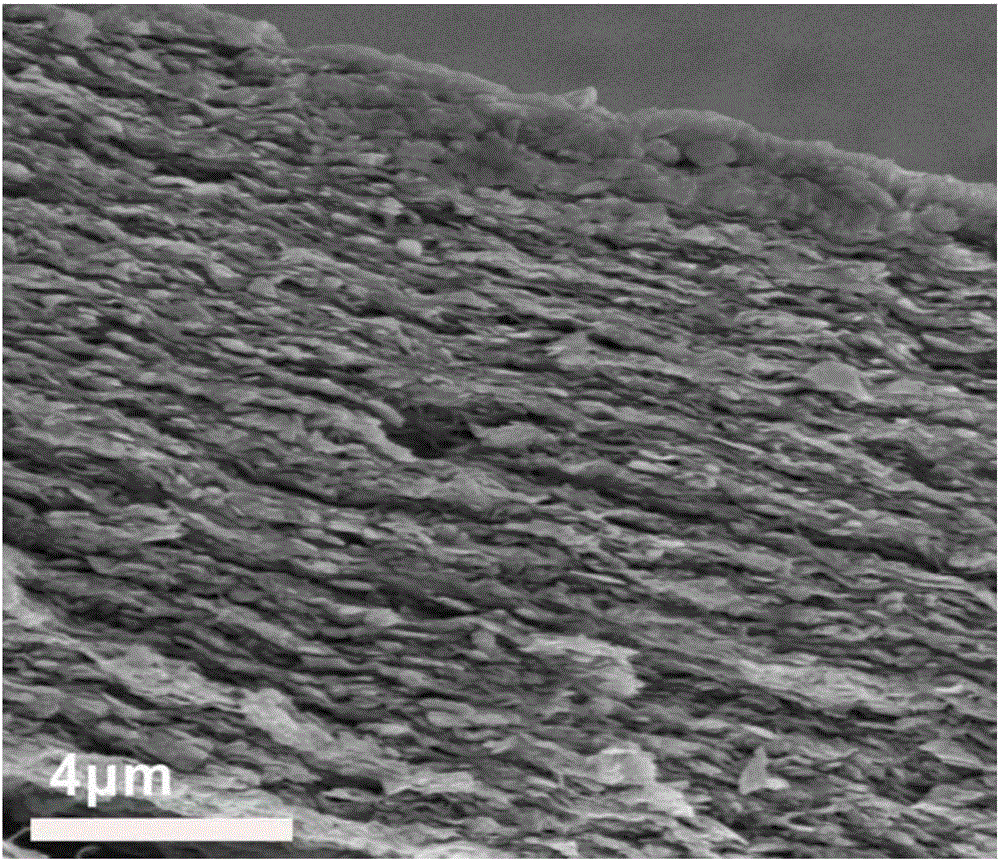

Boron nitride doped composite material and preparation method and application thereof

A composite material and boron nitride technology, applied in the field of doped boron nitride composite material and its preparation, can solve the problems of poor thermal conductivity, complex preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

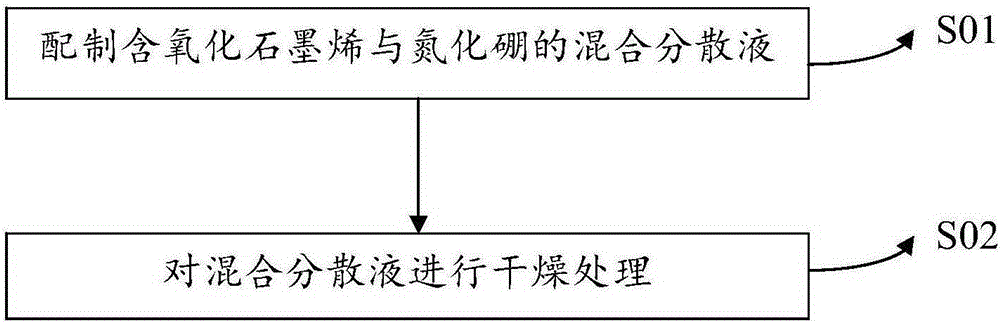

[0031] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned doped boron nitride composite material. The process flow of the nano-silicon-carbon composite negative electrode material preparation method is as follows: figure 1 As shown, it includes the following steps:

[0032] Step S01. Prepare a mixed dispersion containing graphene oxide and boron nitride:

[0033] The graphene oxide dispersion and the boron nitride dispersion are mixed to form a mixed dispersion;

[0034] Step S02. Drying the mixed dispersion:

[0035] The mixed dispersion liquid is subjected to drying treatment.

[0036] Specifically, in order to ensure that the prepared doped boron nitride composite material has satisfactory thermal conductivity and high thermal conductivity, in the embodiment, in the process of preparing the mixed dispersion in the above step S01, the graphite oxide The olefin dispersion and the boron nitride dispersion are ...

Embodiment 1

[0052] A doped boron nitride composite material and a preparation method thereof. The preparation method of doped boron nitride composite material comprises the following specific steps:

[0053] S11. Preparation of graphene oxide dispersion:

[0054] Weigh 1.0 g of graphene oxide powder, add 500 ml of deionized water, and ultrasonically treat for 120 min with a power of 500 W to obtain a graphene oxide dispersion with a mass concentration of 2 mg / ml.

[0055] Wherein, the concrete method of preparing graphene oxide is:

[0056] a. Under the condition of ice bath, 1g of graphite powder, 1g of sodium nitrate and 46ml of concentrated sulfuric acid were stirred evenly at 1000r / min for 15min, then slowly added 6g of potassium permanganate at a rate of 1g / 10min at 600r / min Continue to stir for 60 minutes, keeping the system temperature below 20°C to obtain a mixed solution;

[0057] b. Warm up the mixed solution to 35°C and continue to stir for 1.5h; add 80ml of deionized water ...

Embodiment 2

[0065] The preparation method is the same as that of Example 1, the only difference being that the mass ratio of graphene oxide: boron nitride in step S13 is changed from 1:99 to 10:90.

[0066] After testing, the 80 μm thick graphene oxide-doped boron nitride composite paper can be prepared by the method of Example 2, and the thermal conductivity in the plane direction is 10 W / m·k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com