YAB/SiO2 near-infrared micro-nano luminescent material and preparation method and application thereof

A luminescent material, micro-nano technology, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve the limitation of the improvement of solar cell efficiency, the inability to use sunlight at a high level, and the decrease in light transmittance of EVA film, etc. problems, to achieve the effect of improving transmittance, easy long-term storage, and stable fluorescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

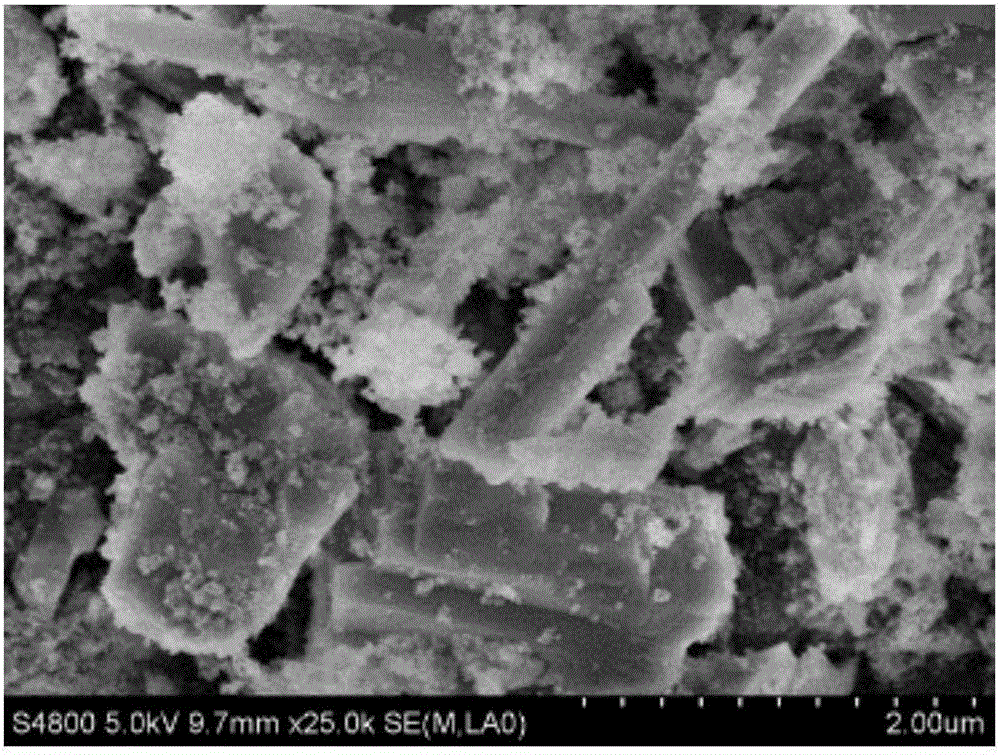

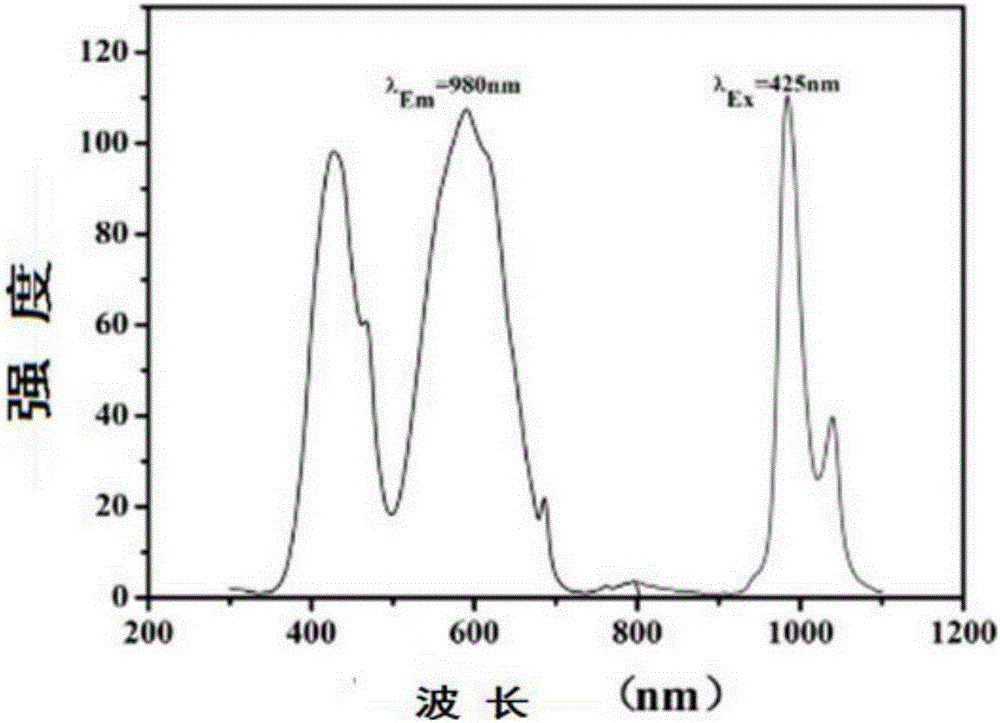

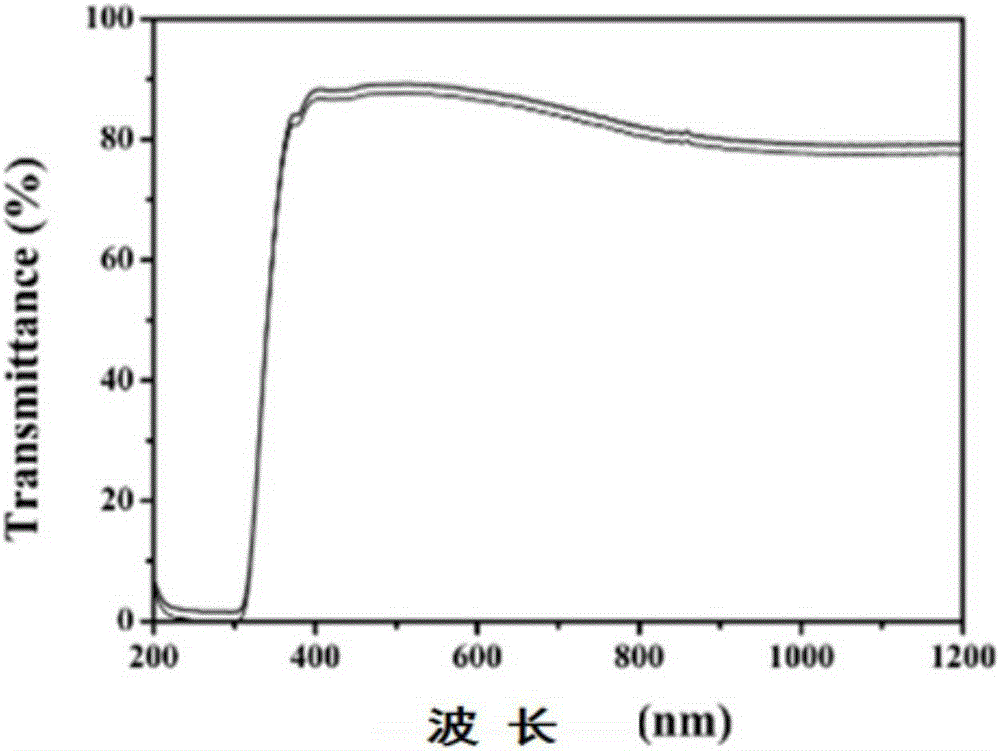

[0045] A kind of YAB / SiO provided by the present embodiment 2 The preparation method of the micro-nano near-infrared emitting material, the specific steps are as follows:

[0046] 1) Weigh 99.3608g (0.44mol) Y 2 o 3 , 149.4300g (1.465mol) Al 2 o 3 , 249.2986g (4.033mol) H 3 BO 3 , 24.2548g (0.05mol) Bi (NO 3 ) 3 ·5H 2 O, 13.7900g (0.035mol) Yb 2 o 3 , 28.010g (0.07mol) Cr(NO 3 ) 3 9H 2 O, the raw materials are wet mechanically stirred in 50% absolute ethanol of the total weight of the mixture until uniformly mixed, and ground and mixed;

[0047] 2) Place the above-mentioned raw materials in a blast drying oven, and dry them at 80°C;

[0048] 3) heating the dried powder to 1200°C in a high-temperature furnace (heating rate 2°C / min), and sintering at a high temperature for 6 hours to obtain a YAB near-infrared luminescent material;

[0049] 4) Wash the above-mentioned YAB near-infrared luminescent material after cooling, centrifuge until the supernatant is colorle...

Embodiment 2

[0057] A kind of YAB / SiO provided by the present embodiment 2 The preparation method of the micro-nano near-infrared emitting material, the specific steps are as follows:

[0058] 1) Weigh 99.3608g (0.44mol) Y 2 o 3 , 149.4300g (1.465mol) Al 2 o 3 , 249.2986g (4.033mol) H 3 BO 3 , 24.2548g (0.05mol) Bi (NO 3 ) 3 ·5H 2 O, 13.7900g (0.035mol) Yb 2 o 3 , 28.010g (0.07mol) Cr(NO 3 ) 3 9H 2 O, the raw materials are mixed and stirred evenly in a high-speed disperser;

[0059] 2) The above-mentioned uniformly mixed powder is heated to 1200°C in a high-temperature furnace (heating rate 2°C / min), and sintered at high temperature for 6 hours to obtain a YAB near-infrared luminescent material;

[0060] 3) Take 200g of the above-mentioned YAB near-infrared luminescent material, and after cooling to room temperature, add 80nm nano-SiO 2 16g, after adding agate beads for ball milling and 5ml deionized water, ball mill for 12 hours;

[0061] 4) The above ball-milled slurry is...

Embodiment 3

[0066] A kind of YAB / SiO provided by the present embodiment 2 The preparation method of the micro-nano near-infrared emitting material, the specific steps are as follows:

[0067] 1) Weigh 99.3608g (0.44mol) Y 2 o 3 , 149.4300g (1.465mol) Al 2 o 3 , 249.2986g (4.033mol) H 3 BO 3 , 24.2548g (0.05mol) Bi (NO 3 ) 3 ·5H 2 O, 13.7900g (0.035mol) Yb 2 o 3 , 28.010g (0.07mol) Cr(NO 3 ) 3 9H 2 O, the raw materials are wet mechanically stirred in 50% absolute ethanol of the total weight of the mixture until uniformly mixed, and ground and mixed;

[0068] 2) Place the above-mentioned raw materials in a blast drying oven, and dry them at 120°C;

[0069] 3) heating the dried powder to 1200°C in a high-temperature furnace (heating rate 2°C / min), and sintering at a high temperature for 6 hours to obtain a YAB near-infrared luminescent material;

[0070] 4) after cooling the YAB near-infrared luminescent material prepared above to room temperature, ball milling for 12 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com