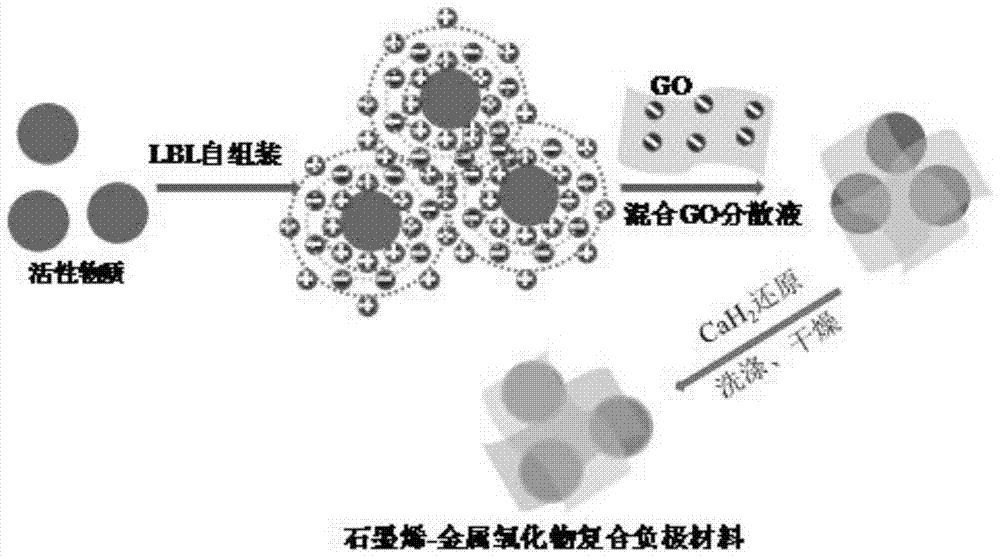

A kind of graphene-metal oxide composite negative electrode material and preparation method thereof

A negative electrode material and oxide technology, which is applied in the field of graphene-metal oxide composite negative electrode materials and its preparation, can solve rare and other problems, and achieve the effects of increasing oxygen vacancies, improving electrical conductivity, and obvious electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

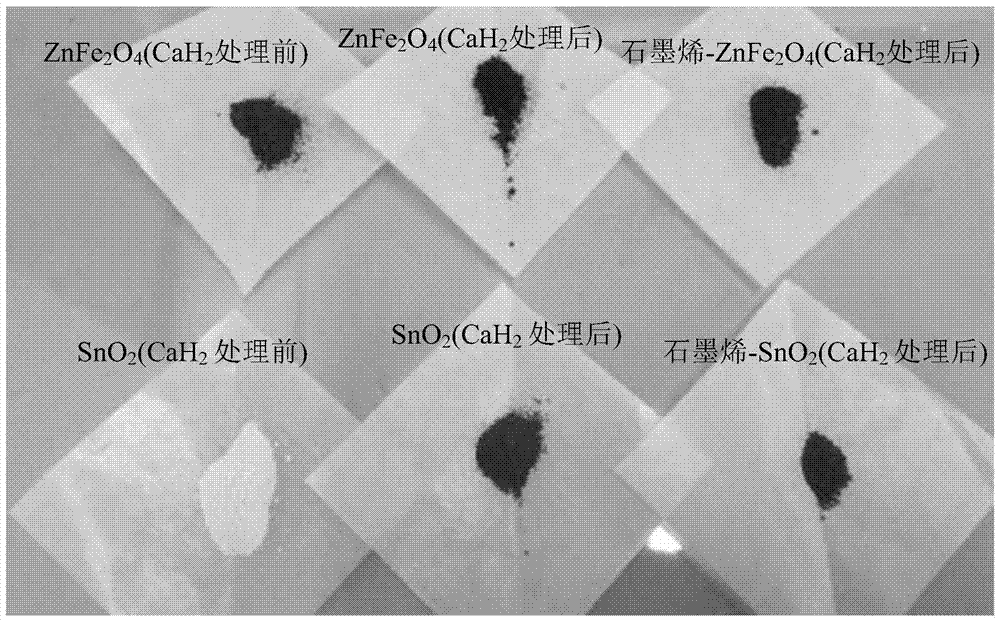

Embodiment 1

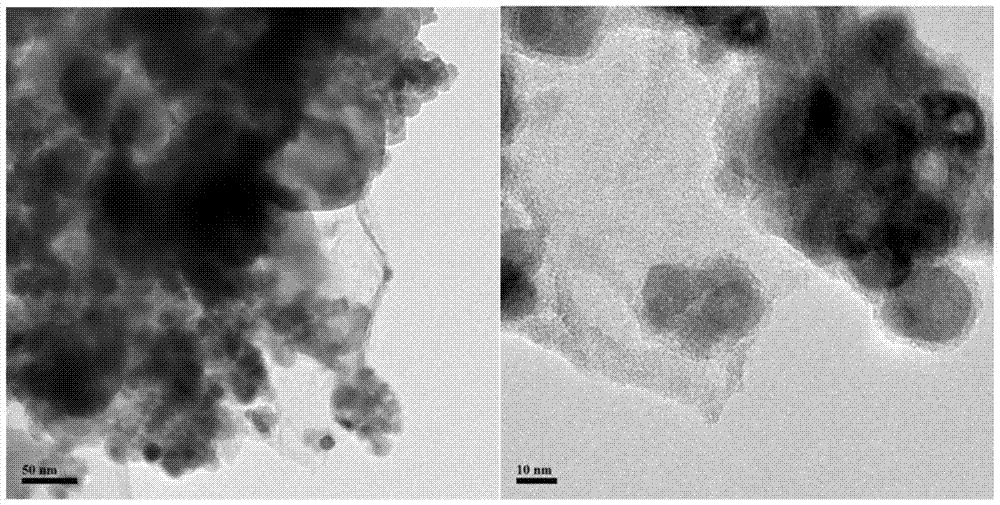

[0040] (1) Prepare two 200mL aqueous solutions containing 1wt.% PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonic dispersion for 10 minutes; Zinc ferrite (with a particle size of 100nm) was sequentially modified by PDDA-PSS-PDDA, filtered, and vacuum-dried at 70°C for 2h. Grind after drying, mark and store;

[0041] (2) Take 0.1 g of the above-mentioned modified zinc ferrite powder and redisperse it in 50 mL of deionized water, and disperse it by ultrasonic for 2 hours to make it uniformly dispersed;

[0042](3) 1 g of graphene oxide was added to 1000 mL of deionized water, ultrasonically dispersed for 5 hours to make it evenly peeled off, and then the insoluble matter was removed by centrifugation to obtain a transparent graphene oxide aqueous solution with a concentration of about 0.2 mg / mL.

[0043] (4) Under the situation of high-speed stirring, get above-mentioned zinc ferrite solution and pour in the graphene aqueous solution of 100mL, continue to stir for 2...

Embodiment 2

[0048] (1) Prepare two 200mL aqueous solutions containing 1wt.% PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonic dispersion for 10 minutes; SnO 2 (particle size is 100-200nm), modified by PDDA-PSS-PDDA treatment sequentially, filtered, and vacuum-dried at 70°C for 2h. Grind after drying, mark and store;

[0049] (2) Take the above modified SnO 2 Powder 0.1g re-dispersed in 50mL deionized water, ultrasonically dispersed for 2 hours to make it evenly dispersed;

[0050] (3) 1 g of graphene oxide was added to 1000 mL of deionized water, ultrasonically dispersed for 5 hours to make it evenly peeled off, and then the insoluble matter was removed by centrifugation to obtain a transparent graphene oxide aqueous solution with a concentration of about 0.2 mg / mL.

[0051] (4) In the case of high-speed stirring, take the above SnO 2 The solution was poured into 50mL of graphene aqueous solution, and left to stand after stirring for 2 hours, vacuum-dried after filtration;...

Embodiment 3

[0056] (1) Prepare two 200mL aqueous solutions containing 1wt.% PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonic dispersion for 10 minutes; Fe 2 o 3 (particle size is 50-70nm), modified by PDDA-PSS-PDDA sequentially, filtered, and vacuum-dried at 70°C for 2h. Grind after drying, mark and store;

[0057] (2) Take the above-mentioned modified Fe 2 o 3 Powder 0.1g re-dispersed in 50mL deionized water, ultrasonically dispersed for 2 hours to make it evenly dispersed;

[0058] (3) 0.1 g of graphene oxide (single layer) was added into 100 mL of deionized water, and ultrasonically dispersed for 5 hours to obtain a transparent graphene oxide aqueous solution.

[0059] (4) In the case of high-speed stirring, take the above-mentioned Fe 2 o 3 The solution is poured into the above-mentioned graphene aqueous solution, and the stirring is continued for 2 hours, then left to stand, filtered and dried in vacuum;

[0060] (5) The dried powder and 0.2g of CaH 2 Mix and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com