Particle manipulation method and particle manipulation device

An operating method and technology for operating devices, applied in separation methods, peptide preparation methods, chemical instruments and methods, etc., can solve problems such as unusability and complex device structure, and achieve the effects of eliminating pollution, easy operation and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

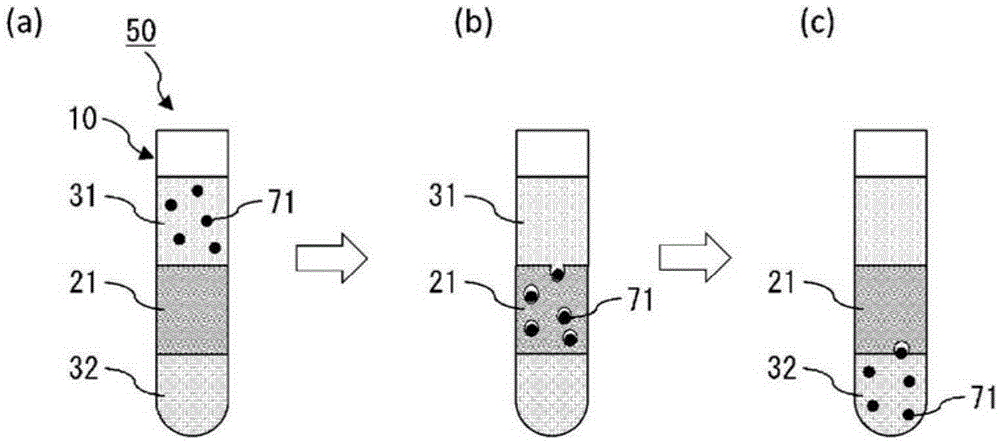

[0136] In Example 1, genomic DNA was extracted from human whole blood using magnetic beads. As magnetic beads, a nucleic acid extraction kit manufactured by Toyobo (MagExtractor TM The magnetic beads attached to -Genome) were resuspended in distilled water to a concentration of 650 mg / Ml.

[0137]

[0138] First, one end of a polypropylene tube (inner diameter 2 mm, outer diameter 3.8 mm, manufactured by Renryi Co., Ltd.) was heated, melted and sealed to obtain a container. In this container, 150 μL of an eluent (distilled water: DNase, RNasefree; manufactured by Nacala Tissue Co., Ltd.), 20 μL of silicone gel (trade name “KSG-15”, manufactured by Shin-Etsu Chemical Co., Ltd.), and the second Cleaning solution (70% ethanol, 10mM Tris-HCl, 10mM EDTA, pH8.0) 150 μL, silicone gel (KSG-15) 20 μL, first cleaning solution (30% ethanol, 2M guanidine hydrochloride) 150 μL, and silicone gel Glue (KSG-15) 20μL. so, such as Figure 4 As shown in (a), the first gel-like medium 121, ...

Embodiment 2

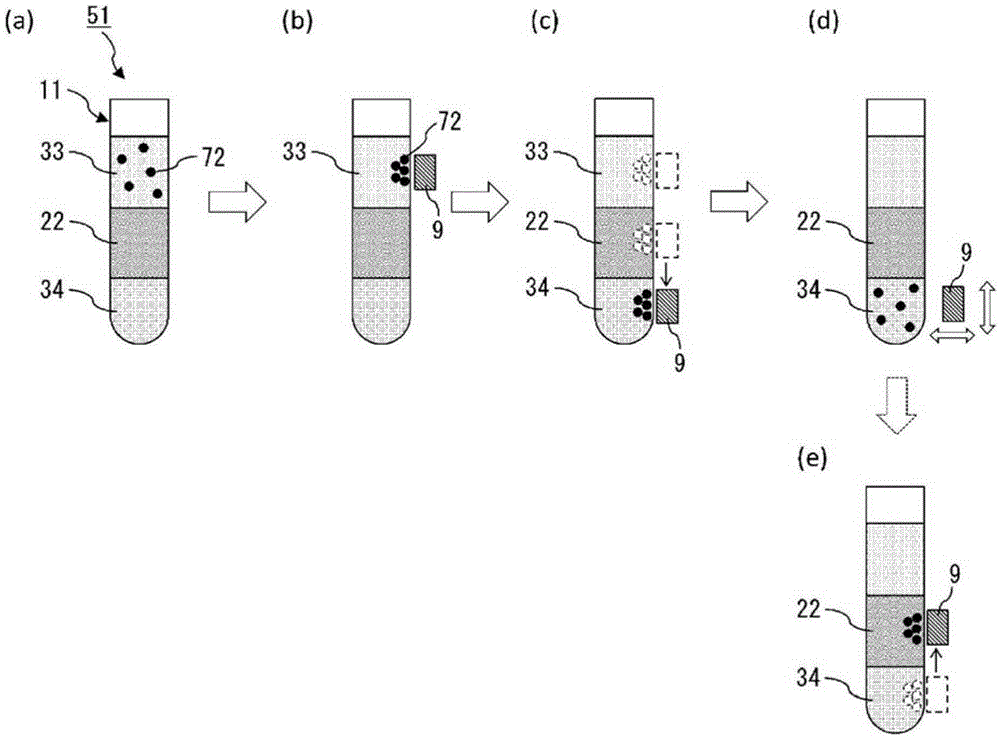

[0159] In Example 2, preparation of a sample for enzyme immunochemical measurement was performed using magnetic beads. As the magnetic beads, protein G-coated magnetic particles (Dynabeads Protein G, manufactured by Life Sciences) were used.

[0160]

[0161] In order to coat the inner wall surface of borosilicate glass capillary tubes (manufactured by Hirschman Laboratories, ringcaps, 200 μl) with silicone, the tube is filled with a silicone coating agent (manufactured by Fuji Rika, siliconized L-25 solution ), the liquid was drawn off after 10 minutes. After washing with distilled water, the inside of the tube was dried with nitrogen gas. Then, the opening at one end of the capillary was sealed with a sealant (cha-seal). From the other opening of the capillary, 60 µL of a PBST solution (0.02% Tween20 containing phosphate-buffered saline) and 20 µL of silicone gel (KSG-15) were filled sequentially from the bottom. After this was repeated 3 times, 40 μL of PBST solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com